Vers. 210422 8

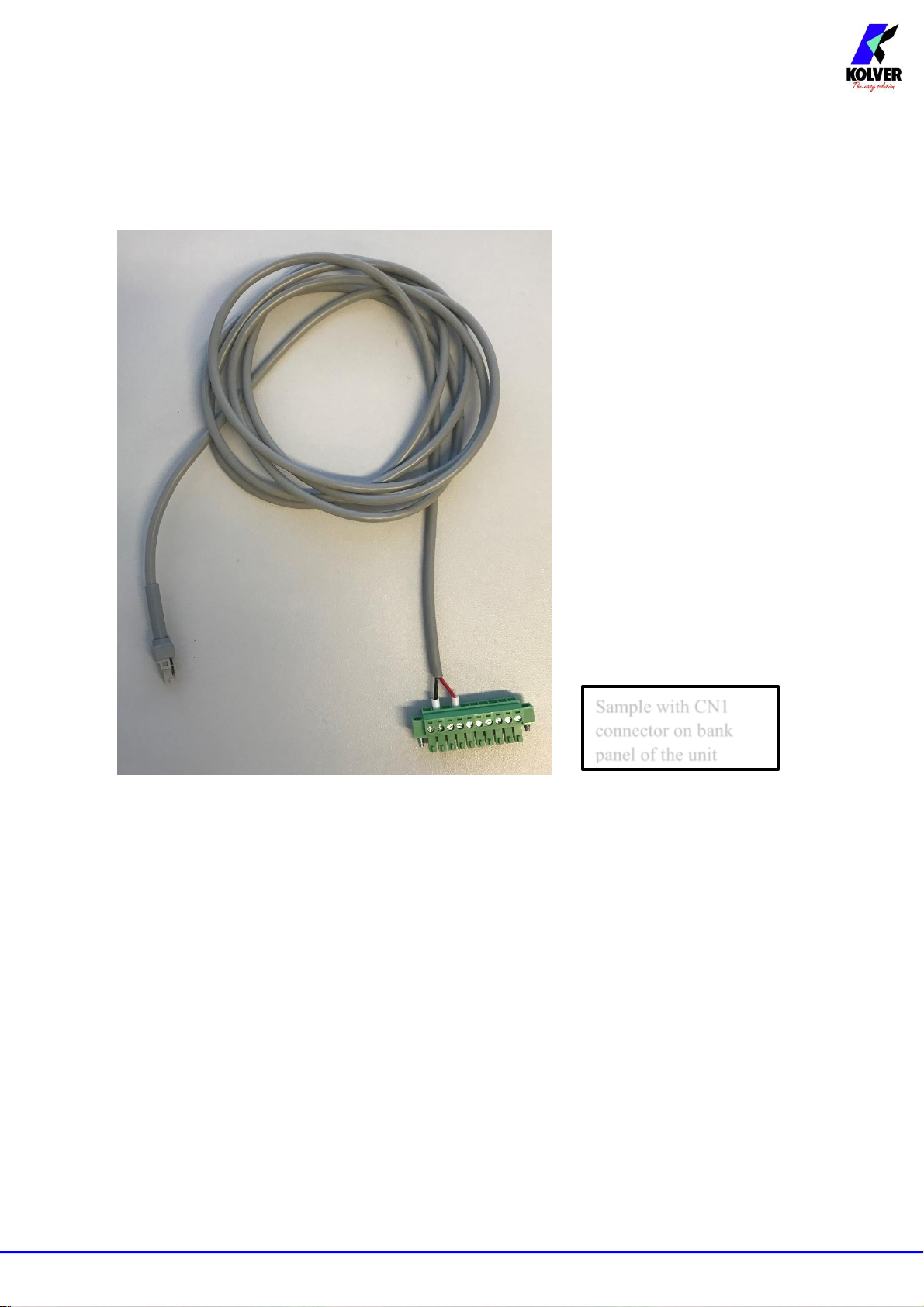

Cable between the control unit and the electrovalve

Cable 2 mt to connect the per connessione elettrovalvola cod.

895092/2M.

The 2 mt cable for connection to the electrovalve (code 895092/2M), it

is supplied with a moulded electrovalve connector on one side and 2

wired pin on the opposite side. The red cable must be connected to the

24V “lever / W” or “Motor ON” signal present in the Output connectors

of the Kolver units; while the black one will be connected to the common

0VDC.

NB: some unit models have specific output signals for use with a self-

advancing arm called “Lever / W”.