Vers. 062721 3

Table of Contents

INTRODUCTION ...............................................................................................................................5

MODELS...............................................................................................................................................5

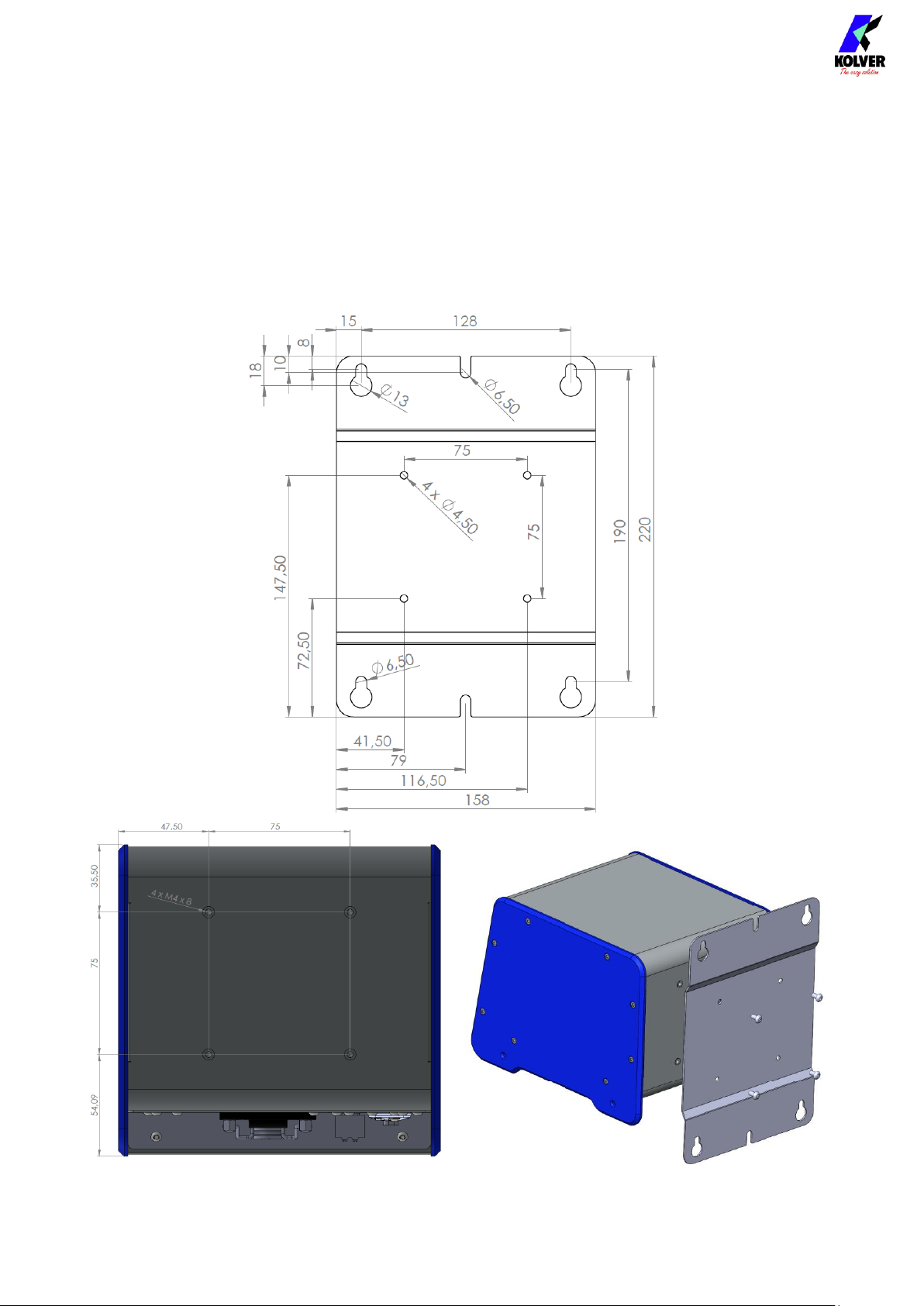

INSTALLATION .................................................................................................................................7

Installation of KDU unit.................................................................................................................7

Connectors .......................................................................................................................................8

Installation of KDS screwdriver....................................................................................................9

Installation of reaction arm......................................................................................................10

QUICK START...................................................................................................................................13

TERMINOLOGY ...............................................................................................................................16

OPERATING THE KDS SCREWDRIVER .....................................................................................18

OPERATING THE K-DUCER CONTROL UNIT.........................................................................20

Main Screen – Program Mode.....................................................................................................20

Main Screen – Program Mode – navigation tree ......................................................................22

Main Screen – Sequence Mode....................................................................................................23

Main Screen – Sequence Mode – navigation tree .....................................................................25

Retrieving and storing the screwdriving results......................................................................26

Connecting a barcode scanner ....................................................................................................28

Connecting Kolver accessories SWBX88, CBS880 ....................................................................28

CONFIGURING THE K-DUCER ...................................................................................................30

MAIN MENU ................................................................................................................................30

PROGRAMS menu .......................................................................................................................31

PROGRAMS menu tree............................................................................................................32

TORQUE & ANGLE menu ......................................................................................................35

RAMP & TIME menu ...............................................................................................................37

REV & PRE-REV menu ............................................................................................................39

OTHER menu ............................................................................................................................40

SEQUENCE SETTINGS menu ....................................................................................................43

SEQUENCE SETTINGS menu tree.........................................................................................44

CURRENT SEQ. menu .............................................................................................................45

GENERAL SETTINGS menu.......................................................................................................47

USB menu.......................................................................................................................................51

USB menu tree...........................................................................................................................53