Vers. 140323 rev

NB. We recommend to grease the JS each 1000 cycles.

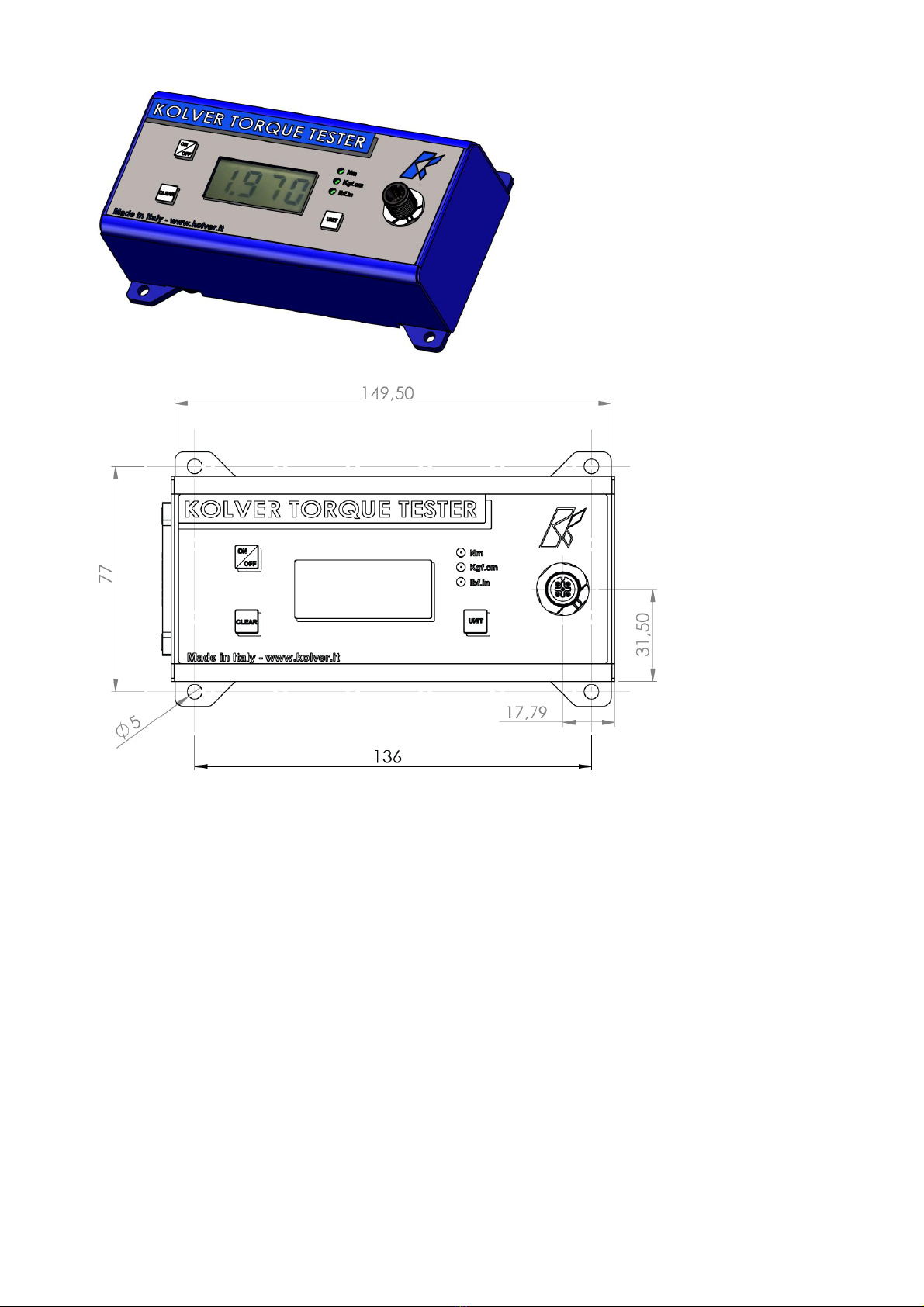

6. STARTING AND OPERATING THE TESTER

1. Immobilize the tester when checking torque values over 1 Nm. This is critical for the safety the operator as

well as for the accuracy of torque measurements during operation.

2. Switch the tester on pushing the ON/OFF key.

If used only with battery check its status. If the tester does not switch on or the display is not clear enough,

please replace the battery. When used it the AC adapter, this will disable the battery. The battery is not

rechargeable. The display will show the main screen:

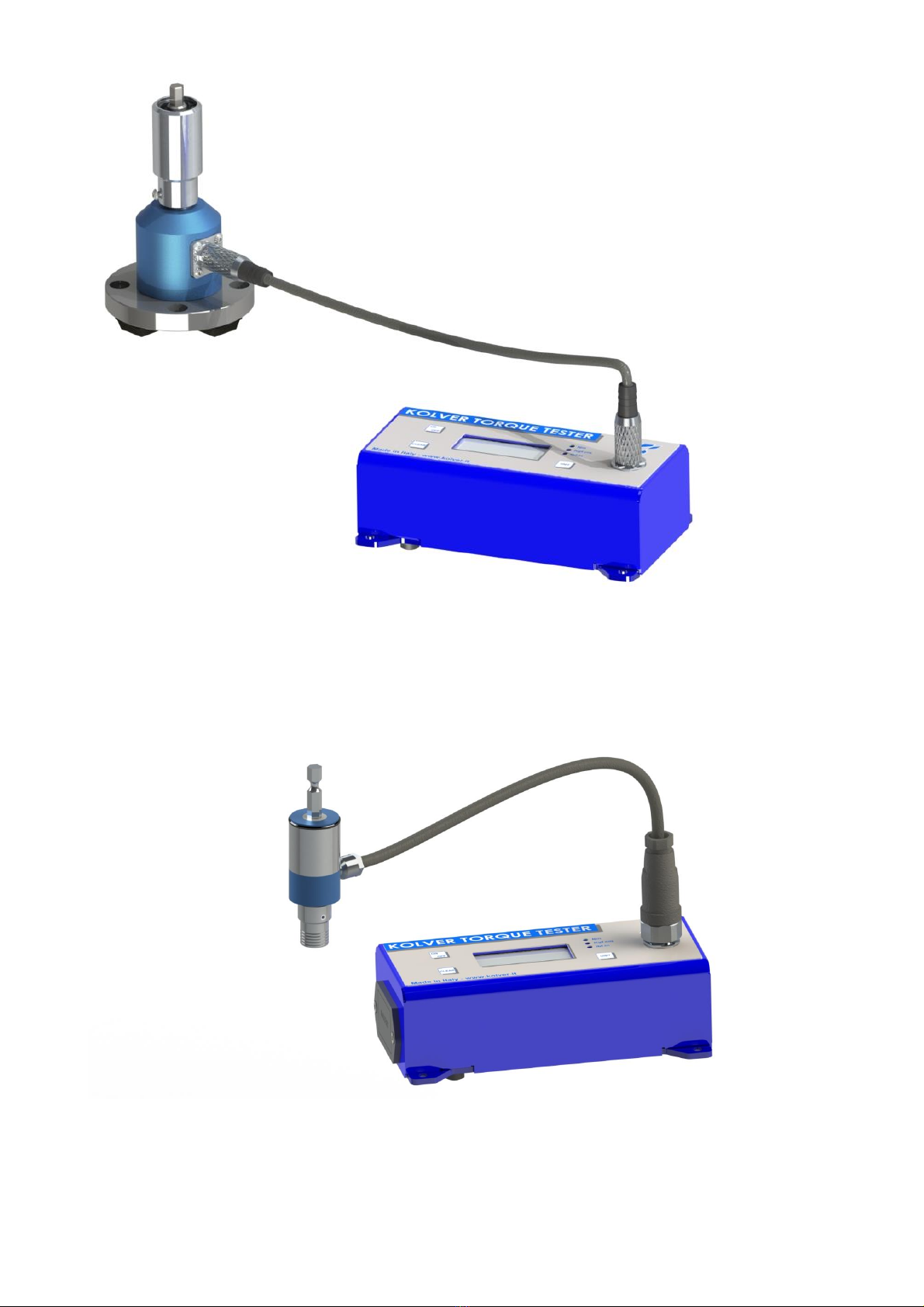

3. Insert the joint simulator into its 13mm hex seat and make sure the screw is in its upper position (if not run

the driver anticlockwise to unscrew it). The tester is ready for a measuring cycle.

In minik1, only unscrew before measuring.

4. Run the joint simulator screw all the way down until it stops and read the torque value on the display. Run

the screw up to be ready for the next cycle.

5. Press the “ON/ESC” key for 3 seconds to switch the tester off. The tester features a built-in auto shut off

mode function to save power when not in use. If there is no activity for 3 minutes, such as key press or no

torque input, the tester will shut down. To restore power press the “ON/ESC” key for 3 seconds

NB. Before starting, always check that the screen displays 0.000. Instead push CLEAR.

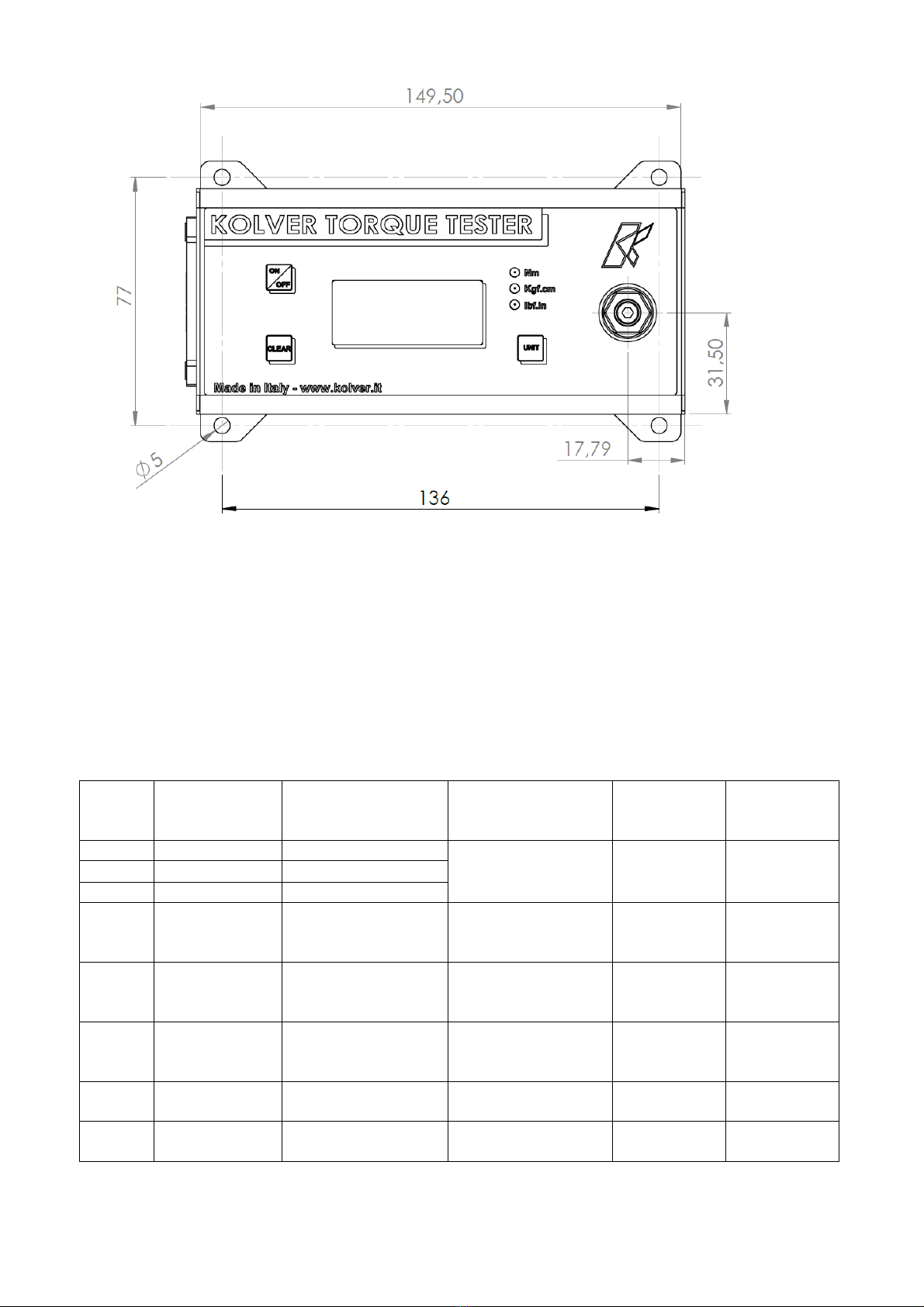

7. SELECTING THE UNIT

MEASURING UNIT: Nm, kgf.cm and lbf.in

To change unit: press Unit key until the desired unit has been selected.

Each unit is indicated by a LED of different color: red for Nm, green for kgf.cm and yellow for lbf.in.

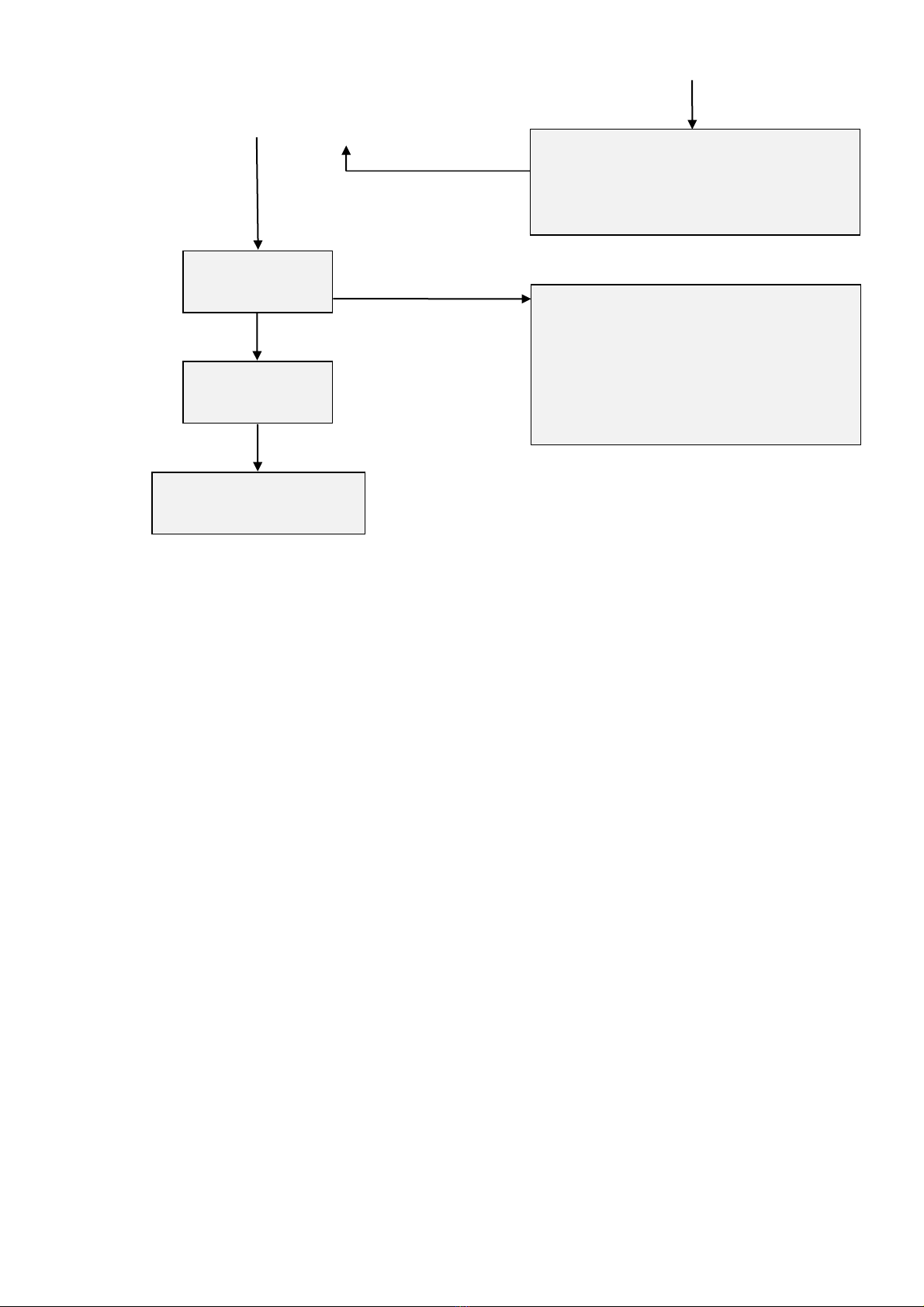

8. SELECTING MANUAL OR AUTO RESET

The flow chart below shows how to select Manual or Auto Reset.

Sens, Cal and Fatc functions (sensitivity, calibration and correction factor) can be modified only by

authorized personnel.

When you select Manual Reset “Coff”: you need to push “CLEAR” to remove readings from the display

and reset all values to zero.

When you select Auto reset “Con”: any new measure will replace the previous one without resetting the

value to zero.