Instruction manual

2 PrimoBox ACB 910 mixing unit for condensing boilers

Table of Contents

1Explanations to the installation and operation manual............................................3

1.1 Safety messages and hazard categories .....................................................3

2Information on safety ...............................................................................................3

2.1 Intended use.................................................................................................3

2.2 Quality control...............................................................................................3

2.3 Qualification of personnel.............................................................................4

2.4 Modifications to the product..........................................................................4

2.5 Using additional parts and accessories........................................................4

2.6 Liability..........................................................................................................4

3Product description..................................................................................................5

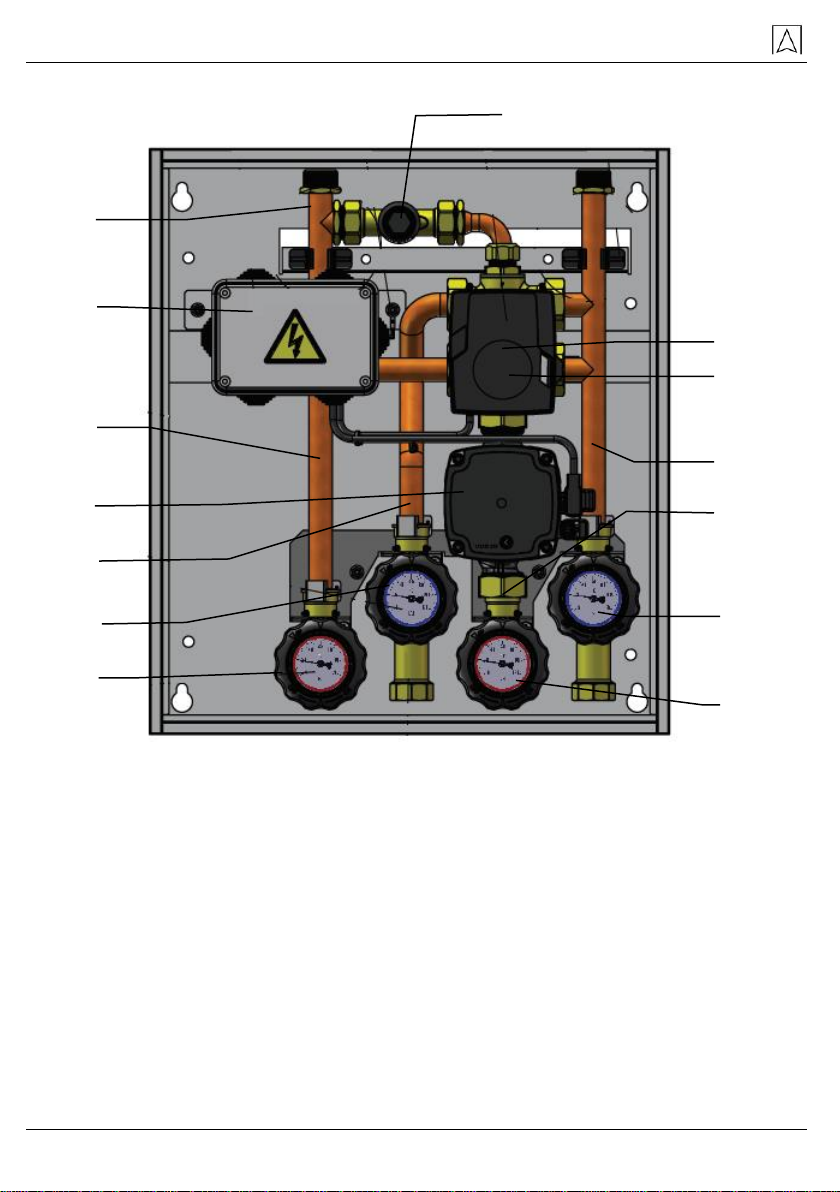

3.1 Construction ................................................................................................6

3.2 Operation......................................................................................................7

3.3 Hydraulic diagram of the ACB 910 unit ........................................................9

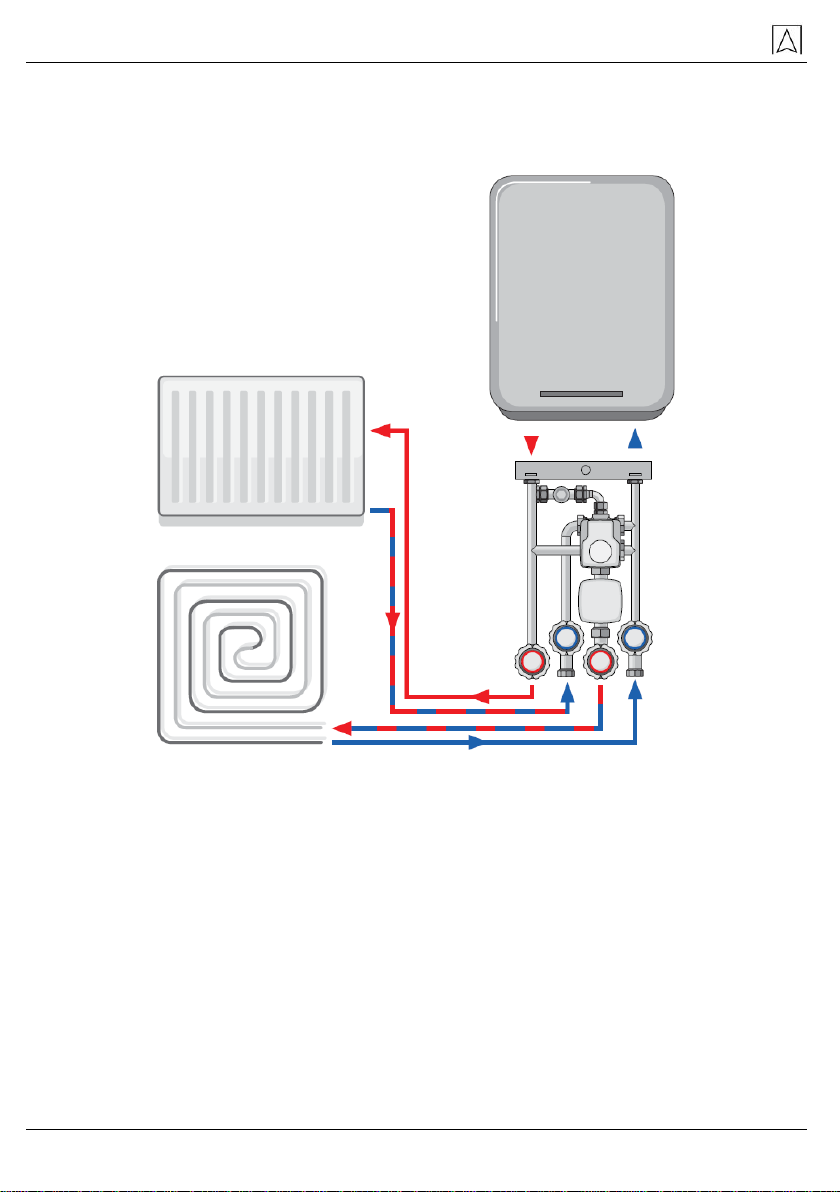

3.4 Application scheme ....................................................................................10

4Specification...........................................................................................................11

4.1 Approvals....................................................................................................11

4.2 Available pressure chart.............................................................................12

5Transport and storage ...........................................................................................12

6Installation and commissioning..............................................................................13

6.1 Wall mounting.............................................................................................13

6.2 Flush mounting...........................................................................................14

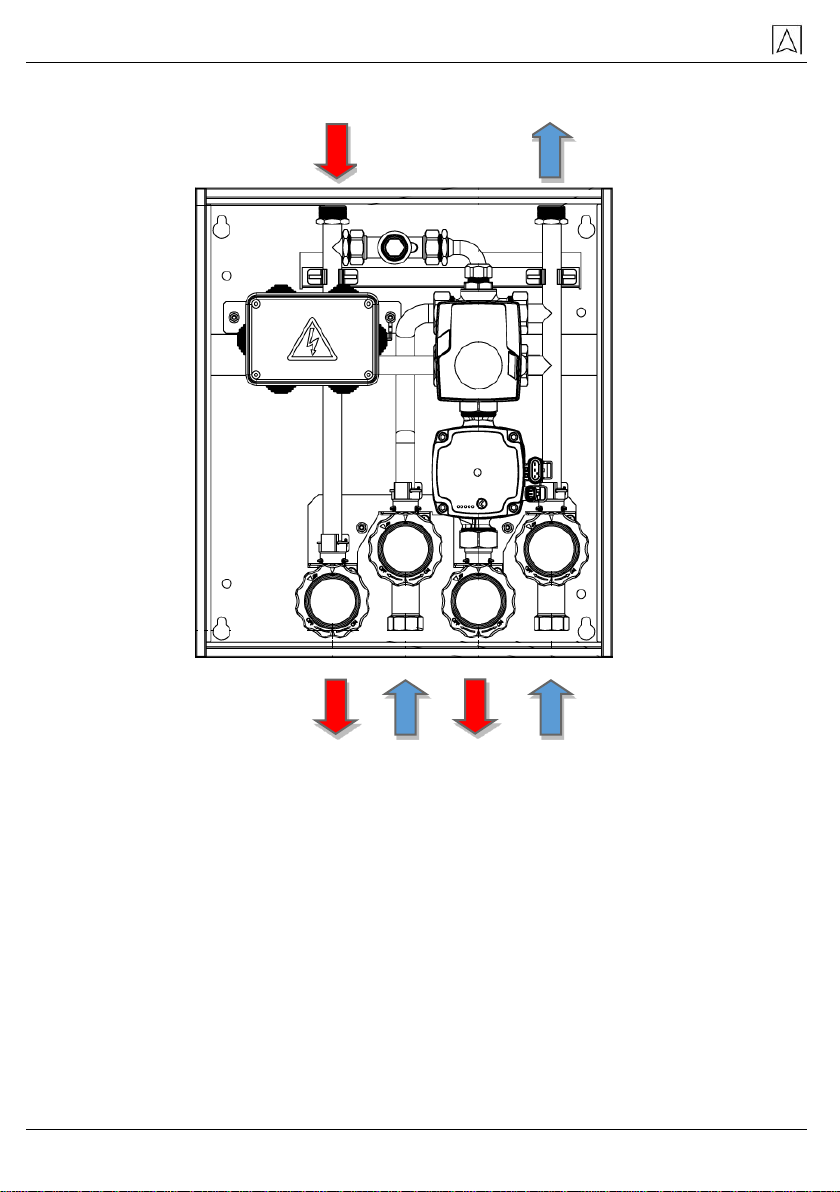

6.3 Hydraulic connections ................................................................................14

6.3.1 Connection to the heat source ...................................................................14

6.3.2 Connection of individual heating circuits ....................................................15

(direct circuit and mixing circuit) ............................................................................15

6.4 Differential pressure relief valve DU...........................................................15

6.5 Electrical connections.................................................................................15

6.6 Filling and venting.......................................................................................17

7Assembly of the ARM ProClick actuator................................................................18

8Switching the actuator to manual operation ..........................................................19

9Maintenance ..........................................................................................................19

10 Decommissioning, scrapping.................................................................................20

11 Warranty ................................................................................................................20

12 Copyright................................................................................................................20

13 Customer satisfaction ............................................................................................20

14 Addresses..............................................................................................................20