TriangleTube PSRKIT80 User manual

Other TriangleTube Boiler Supplies manuals

TriangleTube

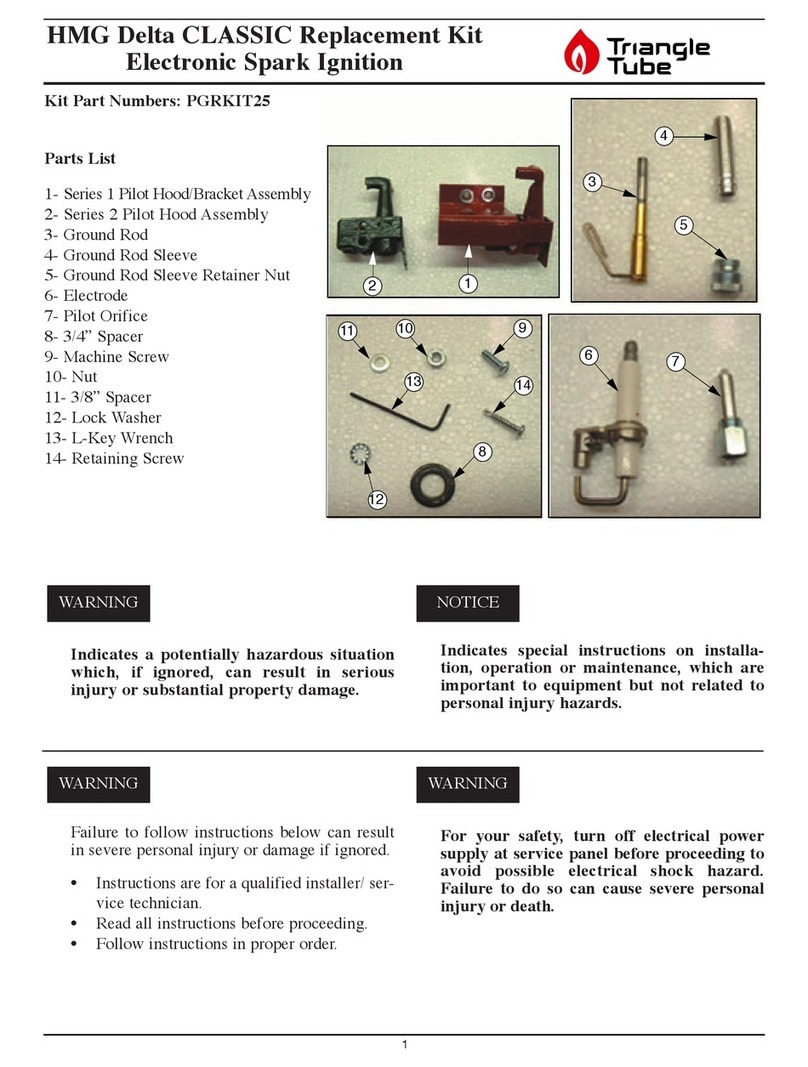

TriangleTube PGRKIT25 User manual

TriangleTube

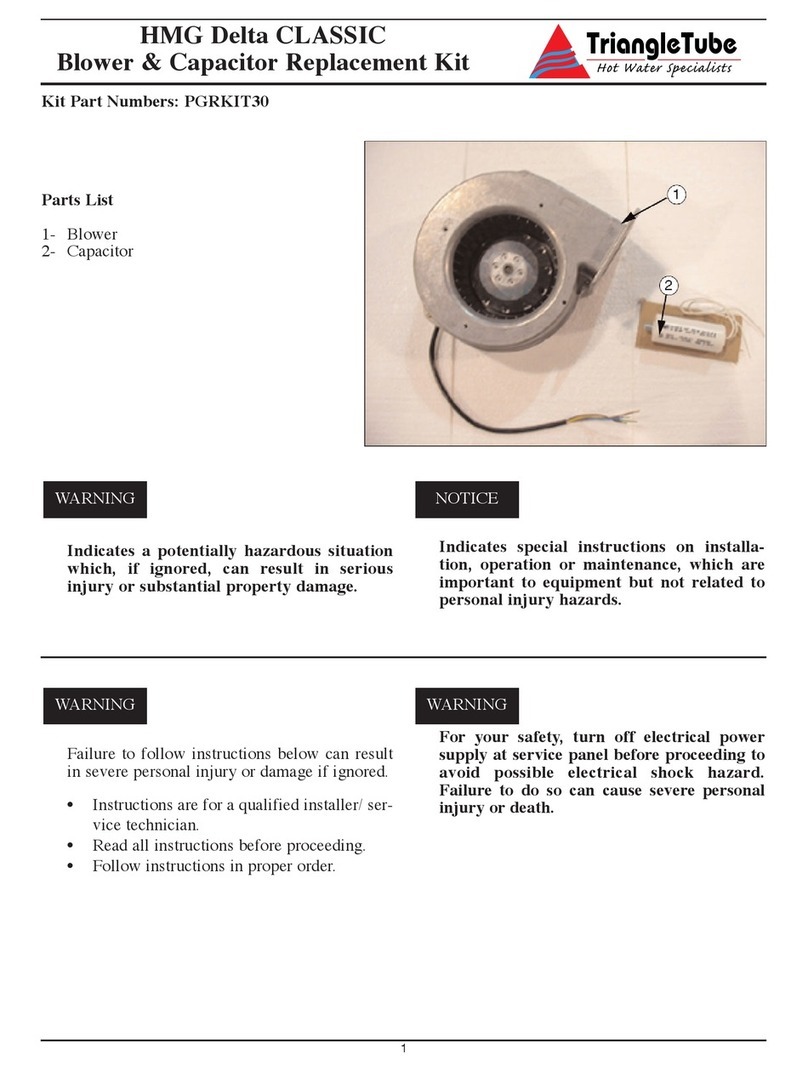

TriangleTube PGRKIT30 User manual

TriangleTube

TriangleTube Instinct INSRKIT134 Use and care manual

TriangleTube

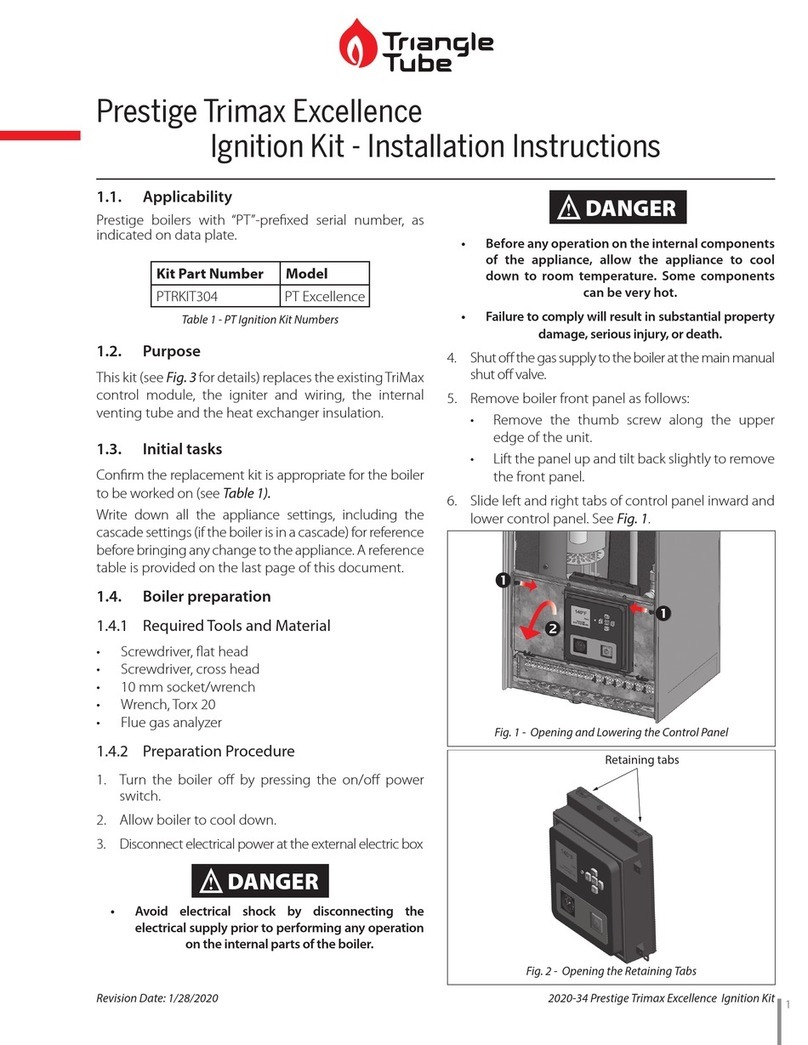

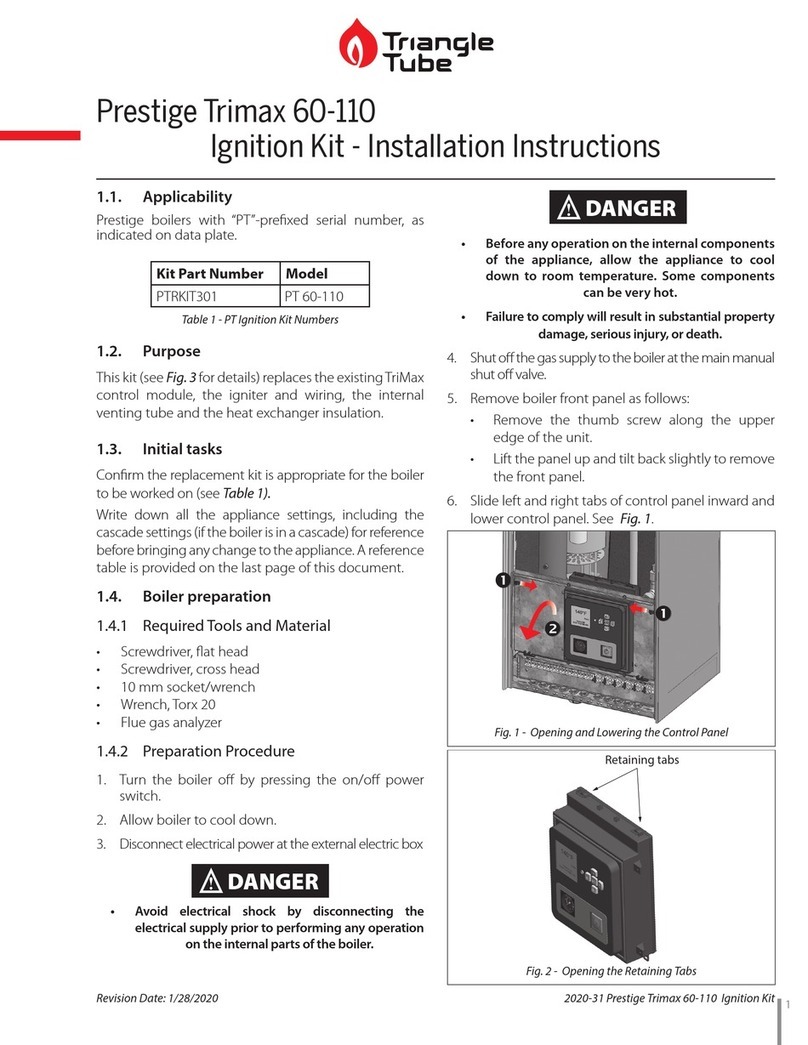

TriangleTube PTRKIT304 User manual

TriangleTube

TriangleTube PSRKIT36 User manual

TriangleTube

TriangleTube CCRKIT32 User manual

TriangleTube

TriangleTube CHALLENGER CCRKIT38 User manual

TriangleTube

TriangleTube PSRKIT44 User manual

TriangleTube

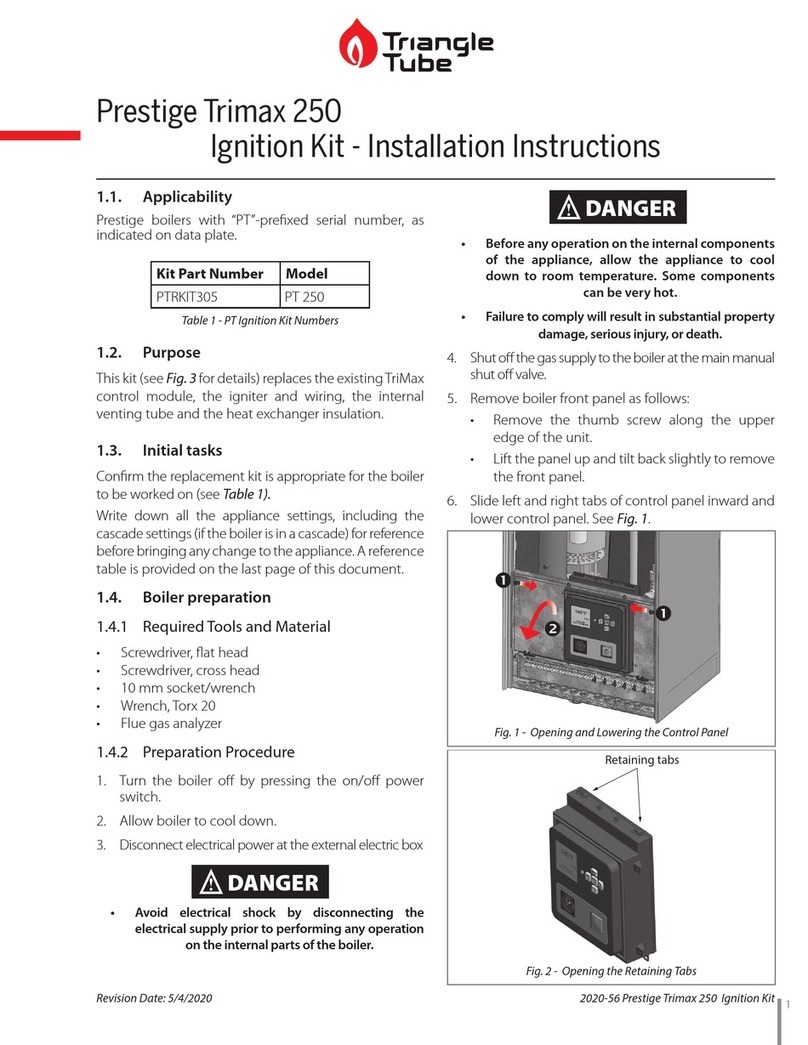

TriangleTube PTRKIT305 User manual

TriangleTube

TriangleTube PSRKIT19 User manual

TriangleTube

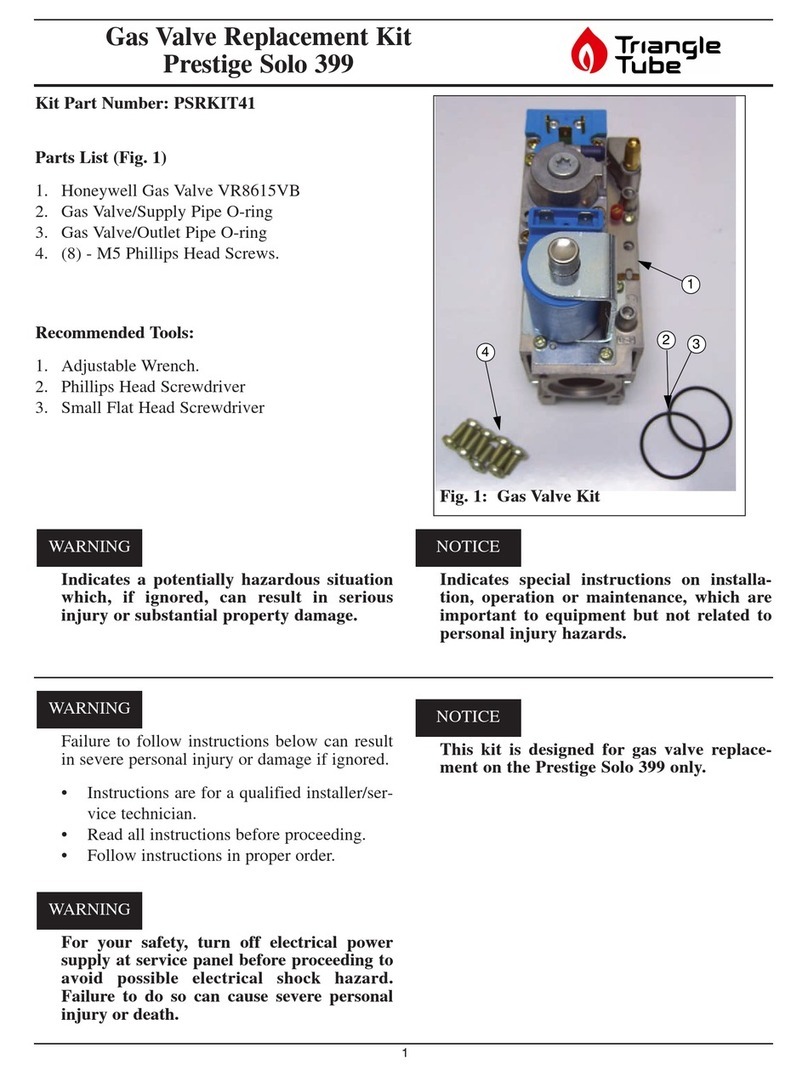

TriangleTube PSRKIT41 User manual

TriangleTube

TriangleTube Instinct SOLO 155-199 User manual

TriangleTube

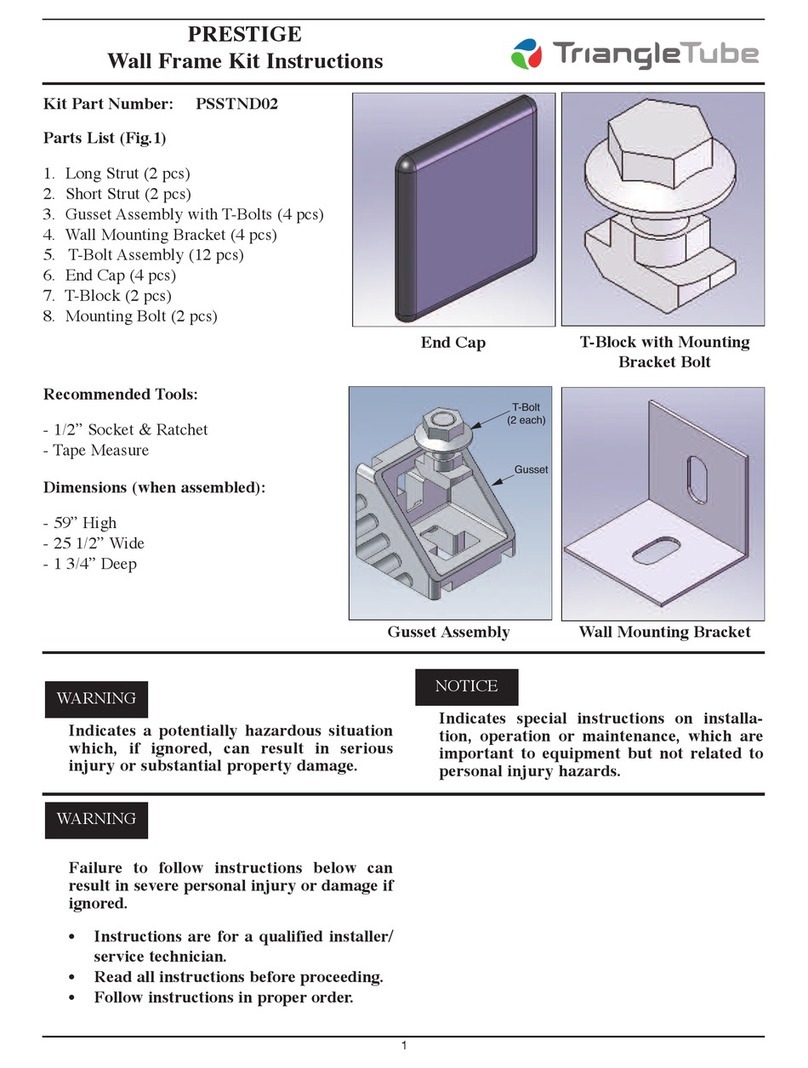

TriangleTube PSSTND02 User manual

TriangleTube

TriangleTube PSRKIT51 User manual

TriangleTube

TriangleTube PSRKIT84 User manual

TriangleTube

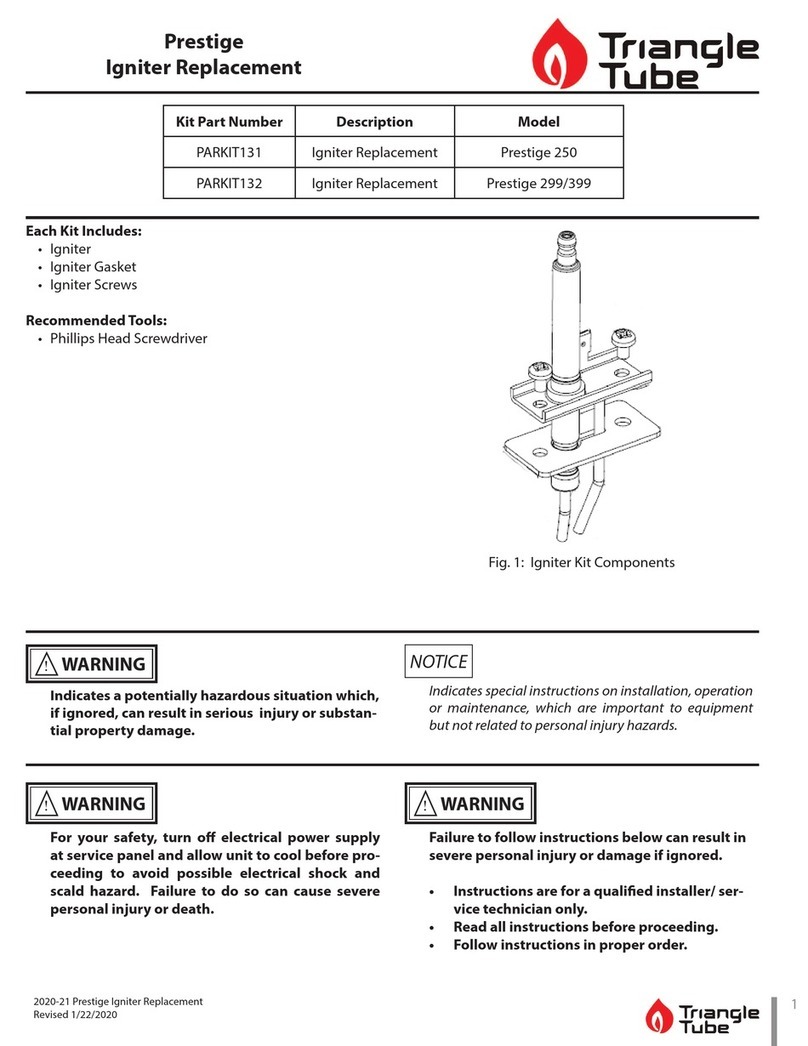

TriangleTube PARKIT131 Use and care manual

TriangleTube

TriangleTube PSRKIT53 User manual

TriangleTube

TriangleTube PTRKIT301 User manual

Popular Boiler Supplies manuals by other brands

Bosch

Bosch CB 28 Original instructions

Volt Polska

Volt Polska GREEN BOOST 3000 product manual

Immergas

Immergas 3.031483 Instruction and warning book

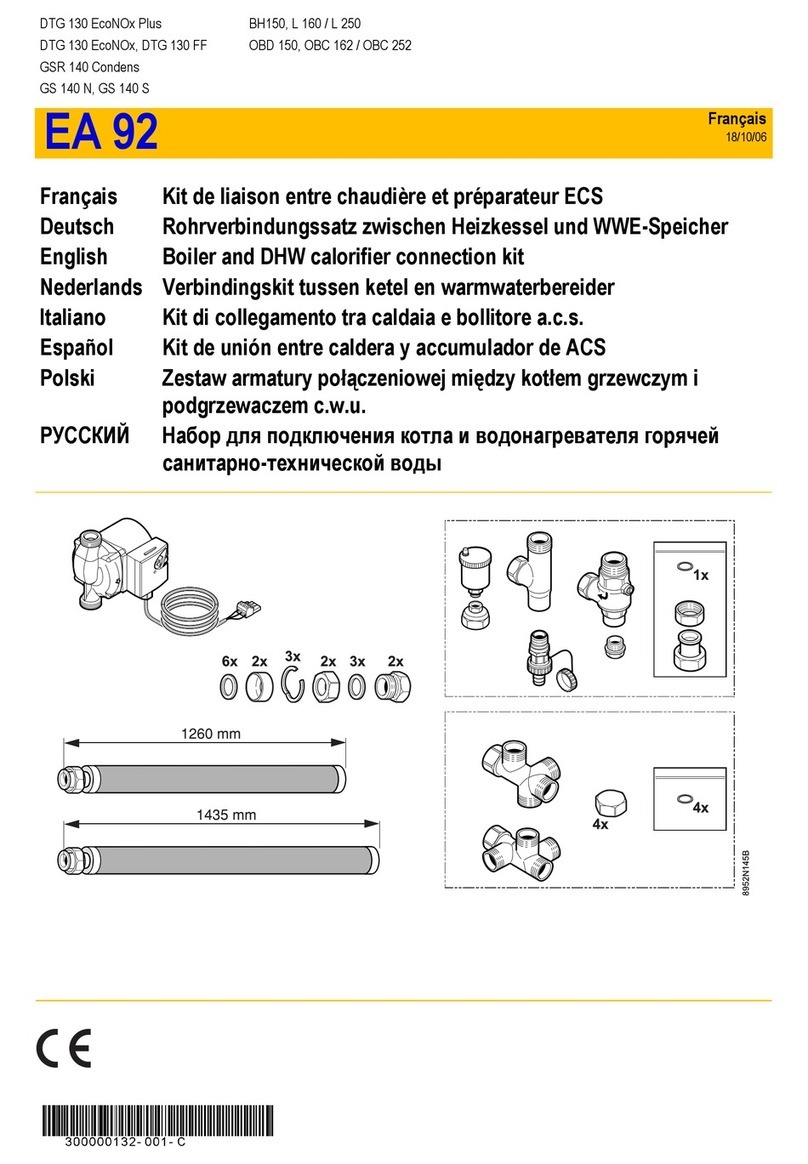

DeDietrich

DeDietrich EA 92 manual

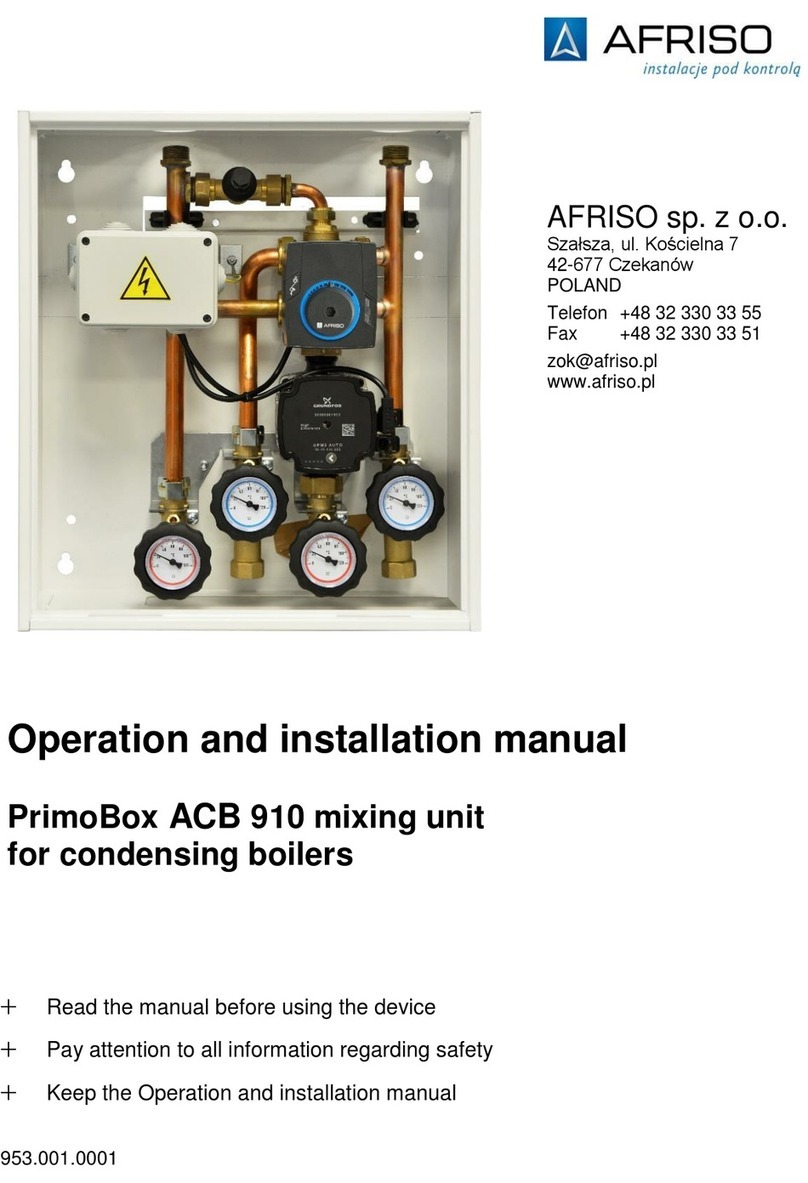

AFRISO

AFRISO PrimoBox ACB 910 Operation and installation manual

Beretta

Beretta CONNECT BASE MIX 1 LE installer and user manual