1.1

Operating

instructions

(Ol)

Theseoperating

instructions

apply

tothe

komax

kappa

220

-

software

versionF103b

andareavailable

rn

German,

English.

French.ltalian.

Spantsh

andPortuguese:

other

languages

areavailableon

request

Thorr cnnqrqt nf 67 n:r

_,,*3€S,

nUrnoereo

consecutlvety.

The

instructions

contain

complete

rnformation

onthe

controls.

theoperationoftheentire

machine.

maintenanceand

adlustmentsas

well

astechnicalspecificatrons.

Electricaldiagrams

anda Iist

of

accessoriesarealso

rncluded.Theoperating

instructionsforthe

variousaccessoriesaredeliveredwith

eachdevice.

Makesuretheyare

not

lostwhen

thedevice

isunpackedandset

up.

The

operating

instructionsarean

integral

pad

ofthekappa

220.Keepthem

near

at

handso

you

can

readilyrefer

to

the

rnformationinthem

atanytime.

Theinstructions

must

beunderstoodandall

itemsin

them

followedbvanvone

responsiblefor

the

transport,rnstallation.

operationand

repair

of

themachine.

Payspecialattention

to Chapter2andthesafetynotesincluded

there.

komaxreseryesthe

right

tomake

technicalchanges

in

thesystem

depictedand

indicatedin

these

instructions

if

suchchangesare

necessary

to

improve

the

komaxkappa.

lf

youneedadditional

copies

of

the

documents,

please

contact

your

komaxrepresen-

tative.

2

Y

a

3

lt

t

I

=

f

j

I

t

r

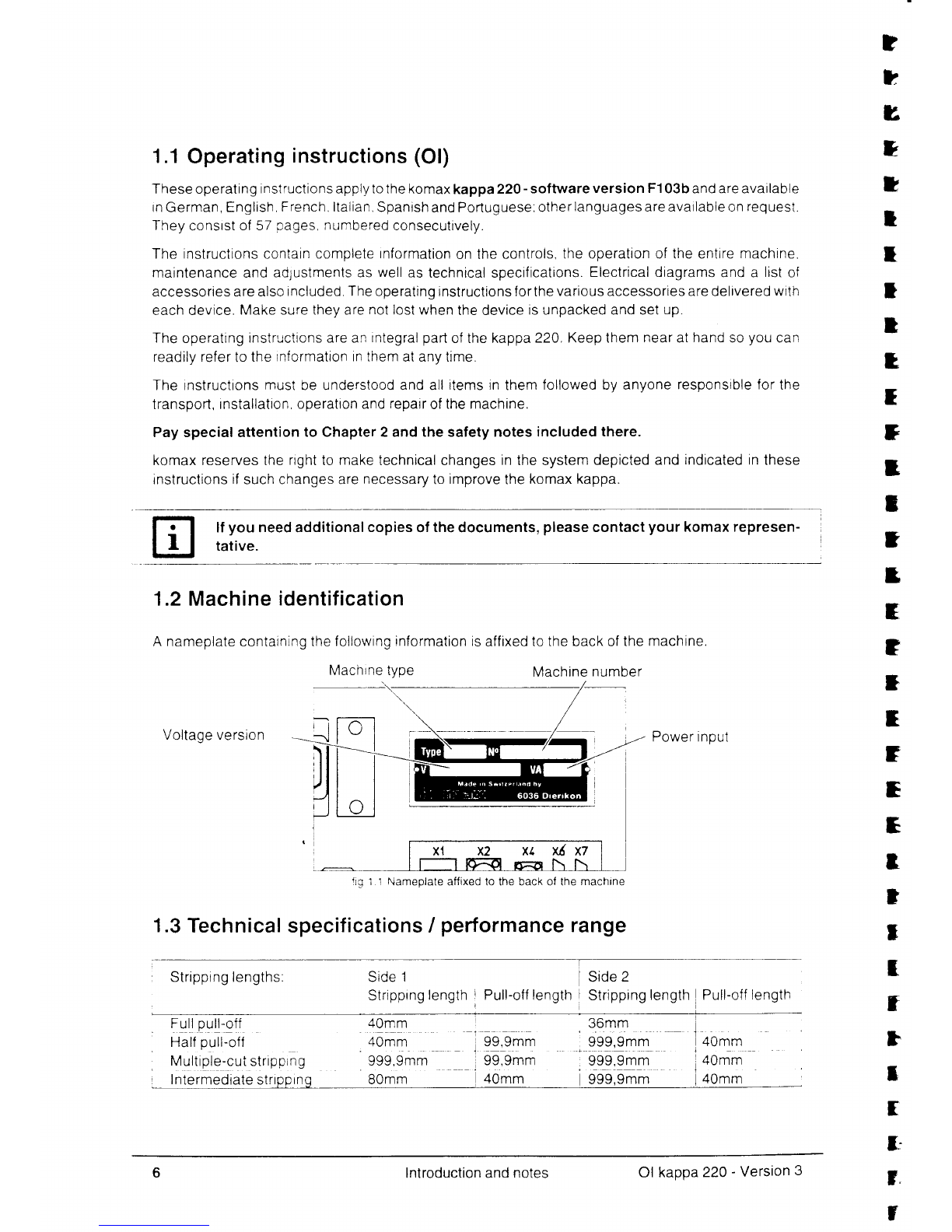

1.2Machine

identification

Anameplatecontainrng

thefollowrnginformationis

affixed

tothebackofthe

machine

Machrnetype Machine

number

Voltageversion Powerinput

fjq 1 1 Nameplateaffixedto the back ol the machine

1.3

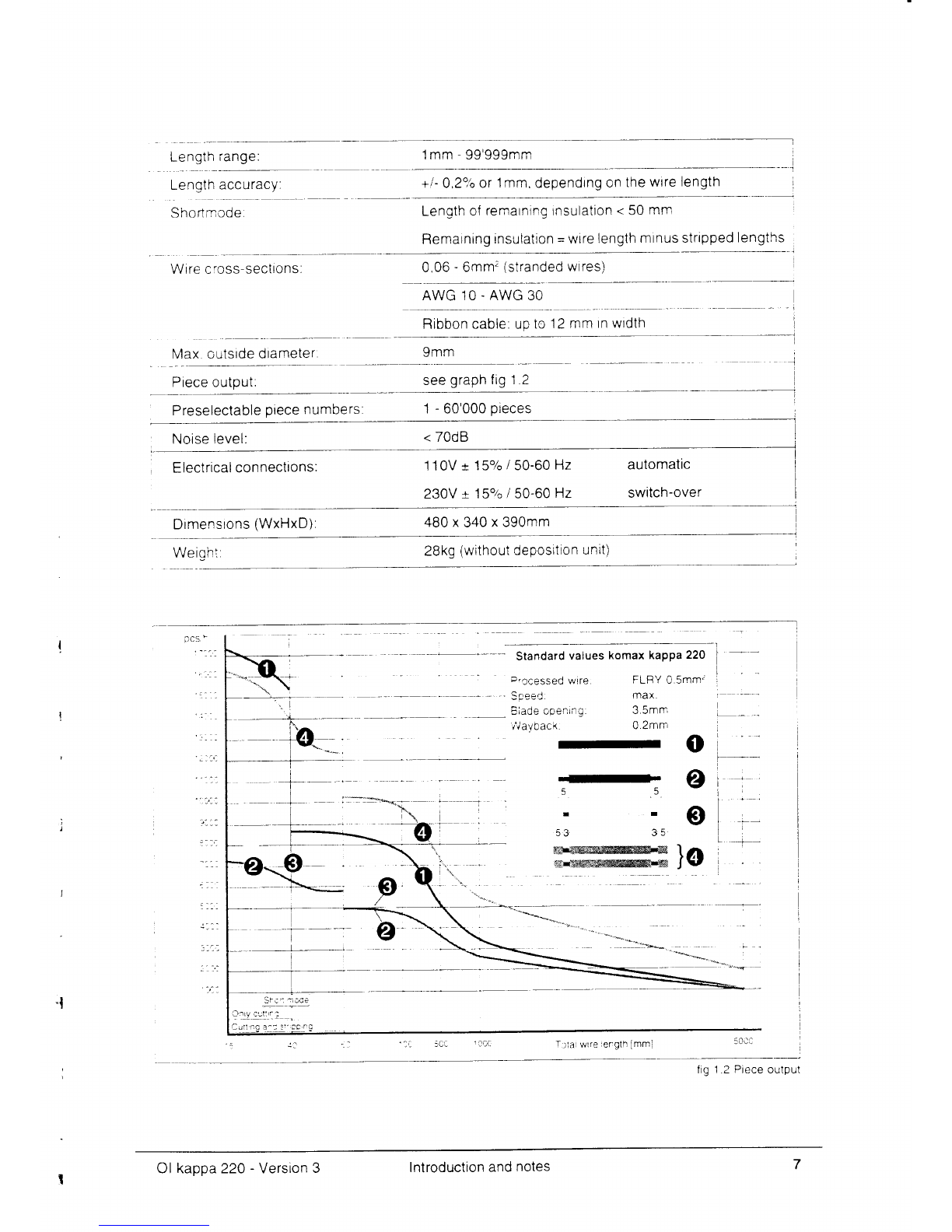

Technicalspecifications/ performance

range

f

f,

C

T

f

r

E

E

t

t

f

xt x6xz

Stripprnglengths Side

1

Strrpprng

length Pull-off

length Side

2

Stripprng

lengthPull-off

length

rq!

pull

9lr

Half

pull-off

, Mullip]glcutstripprng

lntormodiaio qtrinn

_.,,r_rt-le

i sg.srt

99,9mm

40mm

. 36mm

.999,9mm

, 999,pqq

999,9mm

40mm

40mm

999,9mm

B0mm

40mm

40mm

40mm

f

r

]

T

f,

r.

r

lntroductionand

notes Olkappa

220

-

Version

3