CP690HS Preface

ID 20955, Rev. 05 Page iii

P R E L I M I N A R Y

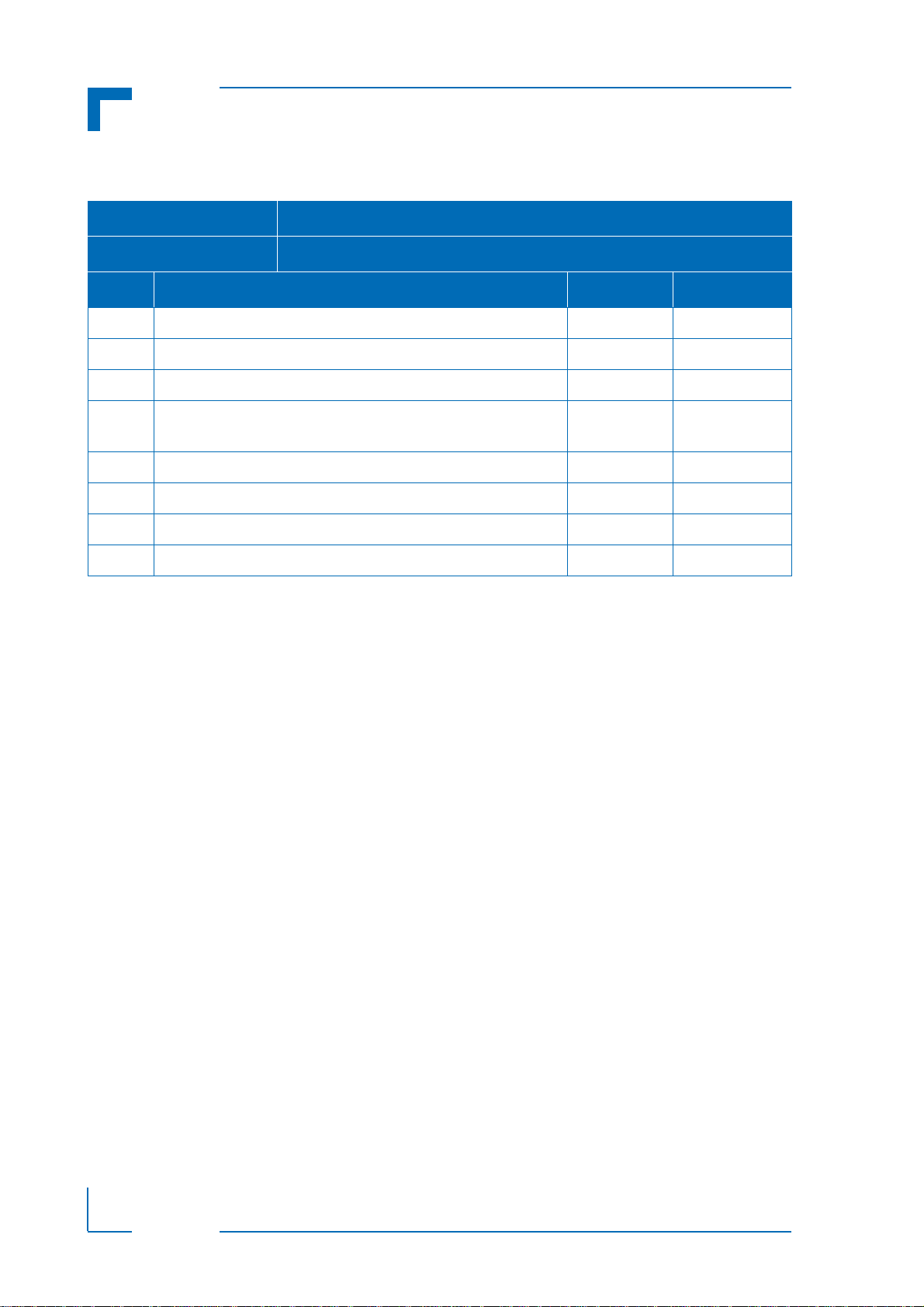

Table of Contents

Revision History .........................................................................................................ii

Imprint ........................................................................................................................ii

Disclaimer ..................................................................................................................ii

Table of Contents ......................................................................................................iii

List of Tables ............................................................................................................vii

List of Figures ...........................................................................................................ix

Proprietary Note ........................................................................................................xi

Trademarks ...............................................................................................................xi

Environmental Protection Statement .........................................................................xi

Explanation of Symbols ...........................................................................................xii

For Your Safety .......................................................................................................xiii

High Voltage Safety Instructions .........................................................................xiii

Special Handling and Unpacking Instructions ....................................................xiii

General Instructions on Usage ...............................................................................xiv

Two Year Warranty ...................................................................................................xv

1. Introduction ............................................................................. 1 - 3

1.1 Overview .................................................................................................1 - 3

1.2 Optional Modules ....................................................................................1 - 4

1.2.1 CP-RIO6-90 Dual PIM Rear I/O Transition Module ........................1 - 4

1.3 System Relevant Information ..................................................................1 - 4

1.4 Functional Block Diagram .......................................................................1 - 5

1.5 Front Panel ..............................................................................................1 - 6

1.6 Board Layout ...........................................................................................1 - 7

1.7 Technical Specifications .........................................................................1 - 8

1.8 Standards ................................................................................................1 - 9

1.9 Related Publications .............................................................................1 - 10

2.1 Board Interfaces ......................................................................................2 - 3

2.1.1 PMC Slots .......................................................................................2 - 3

2.1.1.1 PMC Connectors Pinout .......................................................2 - 4

2.1.2 CompactPCI Bus Connector ...........................................................2 - 7

2.1.2.1 CompactPCI Connector Keying .............................................2 - 7

2.1.2.2 Hot Swap Support ..................................................................2 - 7

2.1.2.3 CompactPCI Connectors J1 and J2 Pinouts ..........................2 - 8