110013961AA

date of change: 18.08.2008

page: 2/19

Contents

ContentsContents

Contents

page

1

11

1

Technical data

Technical dataTechnical data

Technical data of control unit

of control unit of control unit

of control unit ................................

................................................................

................................................................

................................................................

................................................................

................................................................

.......................................................

..............................................

....................... 3

33

3

2

22

2

General description of the control unit

General description of the control unitGeneral description of the control unit

General description of the control unit................................

................................................................

................................................................

................................................................

................................................................

................................................................

.......................................

..............

....... 4

44

4

2.1

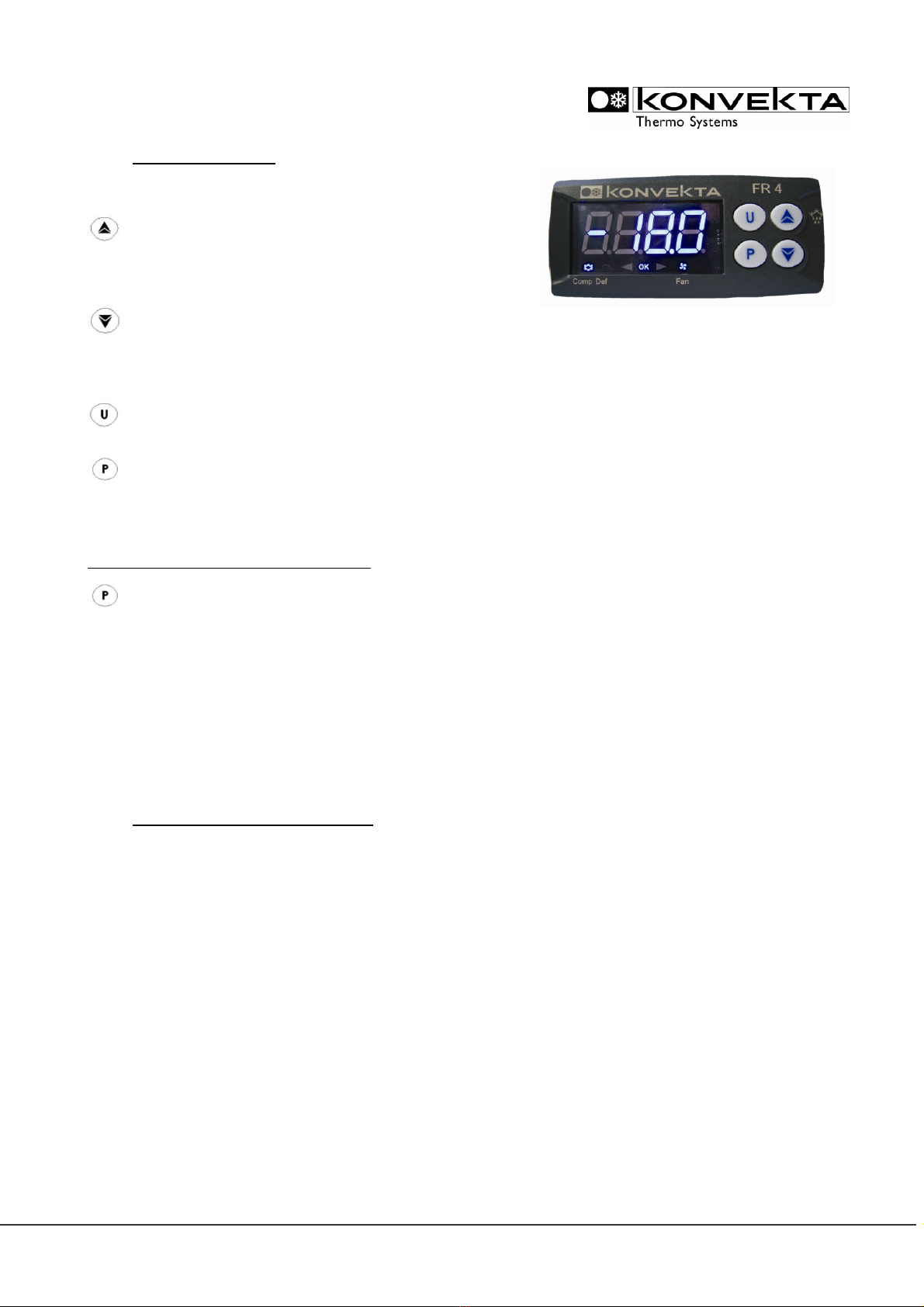

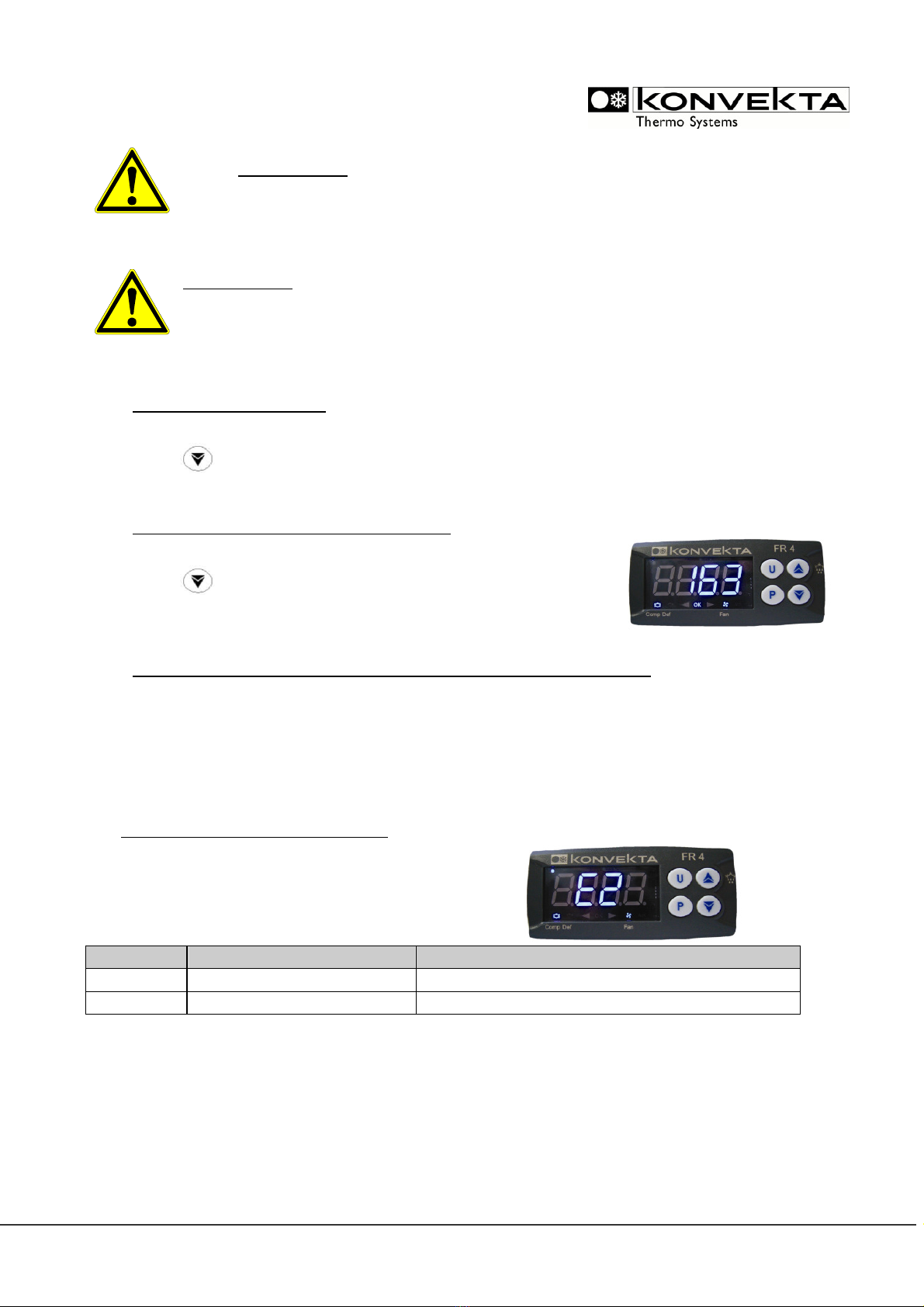

LED-display ...............................................................................................................................................................4

2.2

Programming Menu.................................................................................................................................................4

2.3

Connecting and Safety instructions.....................................................................................................................5

2.4

Functions of buttons...............................................................................................................................................6

2.5

Factory setting / delivery state FR4.....................................................................................................................6

3

33

3

Switching

SwitchingSwitching

Switching-

--

-on the unit

on the uniton the unit

on the unit ................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

......................................

............

...... 7

77

7

3.1

Switching-on the refrigeration unit by button [U] of FR4.............................................................................7

3.2

Indication and change of setpoint........................................................................................................................7

3.3

Sampling of operating hours .................................................................................................................................8

3.4

Sampling of operating hours since last service ................................................................................................8

3.5

Sampling of the temperature values of room sensor and evaporator sensor..........................................8

4

44

4

Faults

FaultsFaults

Faults

–

––

–

indications and signals

indications and signalsindications and signals

indications and signals ................................

................................................................

................................................................

................................................................

................................................................

................................................................

......................................................

............................................

...................... 8

88

8

5

55

5

Adjustment of

Adjustment of Adjustment of

Adjustment of P

PP

Parameters in the

arameters in the arameters in the

arameters in the m

mm

men

enen

enu

uu

u................................

................................................................

................................................................

................................................................

................................................................

................................................................

.......................................

..............

....... 9

99

9

5.1

Example for change of a parameter, here parameter defrost interval “di nt”..........................................9

5.2

Conversion to cooling with recirculated air defrosting / or replace a FR1, FR2 or FR3.......................9

5.3

Conversion to cooling – heating with hotgas – defrosting with hotgas.................................................. 10

6

66

6

Control of defrosting

Control of defrostingControl of defrosting

Control of defrosting................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

....................................

........

.... 10

1010

10

7

77

7

Configuration of the parameters with “FR 4

Configuration of the parameters with “FR 4 Configuration of the parameters with “FR 4

Configuration of the parameters with “FR 4 c

cc

copy

opyopy

opy-

--

-k

kk

key”

ey”ey”

ey” ................................

................................................................

................................................................

................................................................

.........................................

..................

......... 11

1111

11

8

88

8

Logi

LogiLogi

Logic

cc

c >>

>> >>

>> Explanations for the functions of the control conditions

Explanations for the functions of the control conditionsExplanations for the functions of the control conditions

Explanations for the functions of the control conditions................................

................................................................

.......................................................

..............................................

....................... 12

1212

12

8.1

Cooling and defrosting with hot gas >> delivery state FR4 ............................................................... 12

8.2

Cooling and defrosting with recirculated air >> see changes in parameters point 5.2....................... 12

8.3

Neutral zone cooling + heating with hot gas) and defrosting with hot gas >> see changes in

parameters point 5.3. .......................................................................................................................................... 12

9

99

9

Connection diag

Connection diagConnection diag

Connection diagram

ramram

ram

a

aa

and

nd nd

nd p

pp

parameter

arameterarameter

arameter chart

chart chart

chart ................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................ 13

1313

13

9.1

Connection diagram ............................................................................................................................................ 13

9.2

Parameter chart.................................................................................................................................................... 13