Precautions

(1) Use the push button switch for both positive and negative (KASUGA ELECTRIC WORKS LTD. BSW-330B). (This cannot be

used for RES-4024, RES-7524.)

(2) Use N120-H of GS or equivalent for the battery.

(3) If the battery charge has become low and load is given to the motor (i.e. larger electricity flows), the voltage will decrease

extremely. Charge the battery or replace it with a new one. If you use a battery with a low charge, excess current will flow at

startup, which may cause the voltage to decrease. As such, the brake will not open nor will the motor rotate, which may

result in burnout. To avoid such events, always check the battery charge. Charge the battery if the voltage drops by 3 V or

more at startup. It drops by only 0.4 V for a new or freshly charged battery.

(4) Use a power supply cord with a diameter of 5.5mm2.

(5) Be sure to use a safety breaker and fuse to protect the motor. (For safety breaker, we recommend Tempearl Industrial Co.,

Ltd.'s wiring breaker.)

(1) CAUTIONARY INSTRUCTIONS

1) Use a push-button switch of forward-stop-reverse type.

2) Use a GS battery of N120H or an equivalent.

3) When battery capacity is lowered charge or replace the battery with a new one as the voltage drops extremely when load is

applied to the motor. Please pay attention to battery capacity at all times. Perform charging if the voltage drops more than 3V

at start-up. With a new battery, voltage drop is up to 0.4V only.

4) Use 5.5mm2wires (cords) of 6 cores between the push-button switch and the motor lead wires and 5.5mm2wires of 2 cores

between the battery and the motor lead wires.

5) Be sure to use safety breakers and fuses to protect the motor.

6) Refrain from extending the wire over 10 m as far as possible. If longer extension is necessary, use a wire of 5.5mm2or larger.

7) Connect the solderless terminals firmly with screws and nuts. Loose fastening can generate heat and may cause burning.

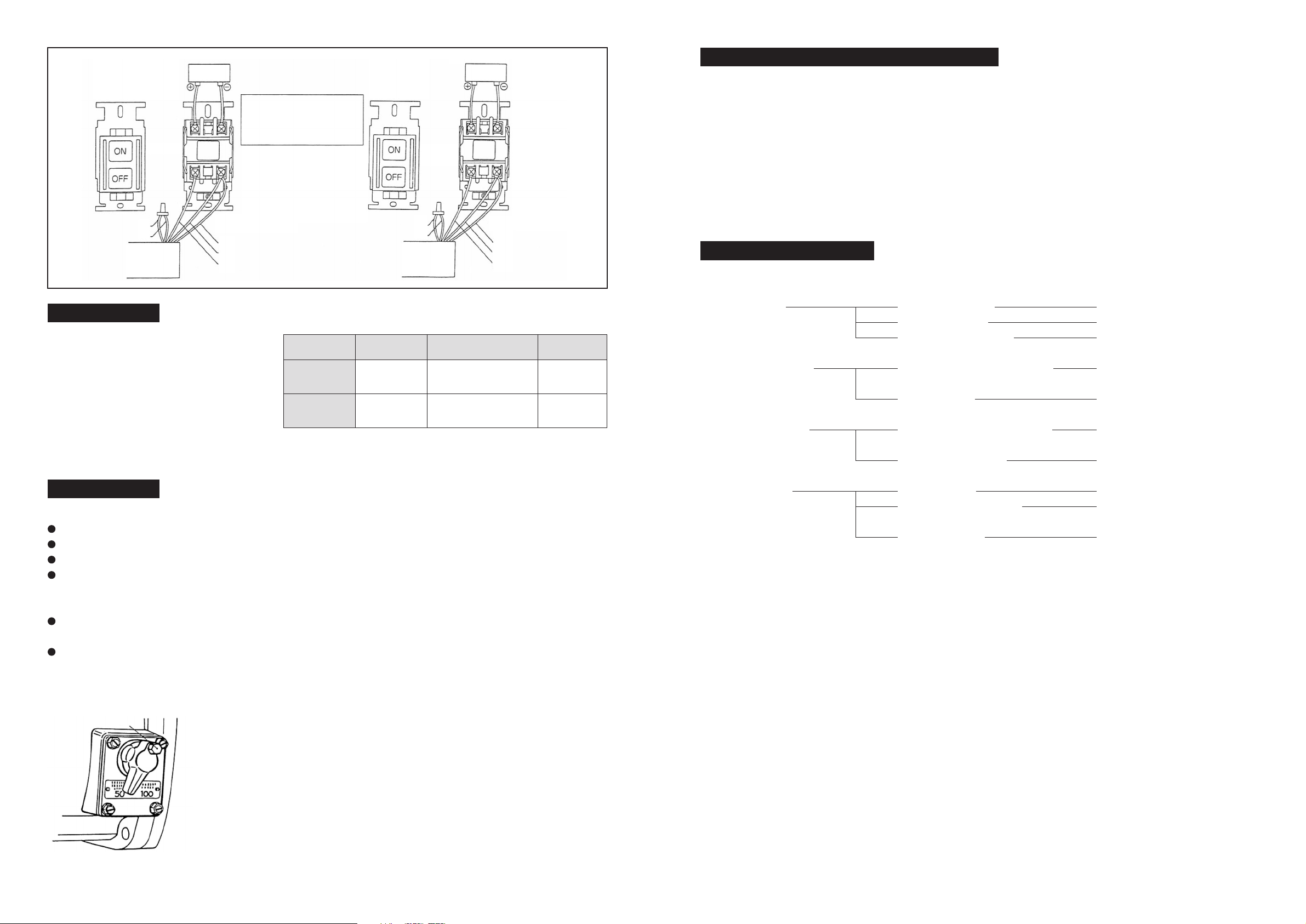

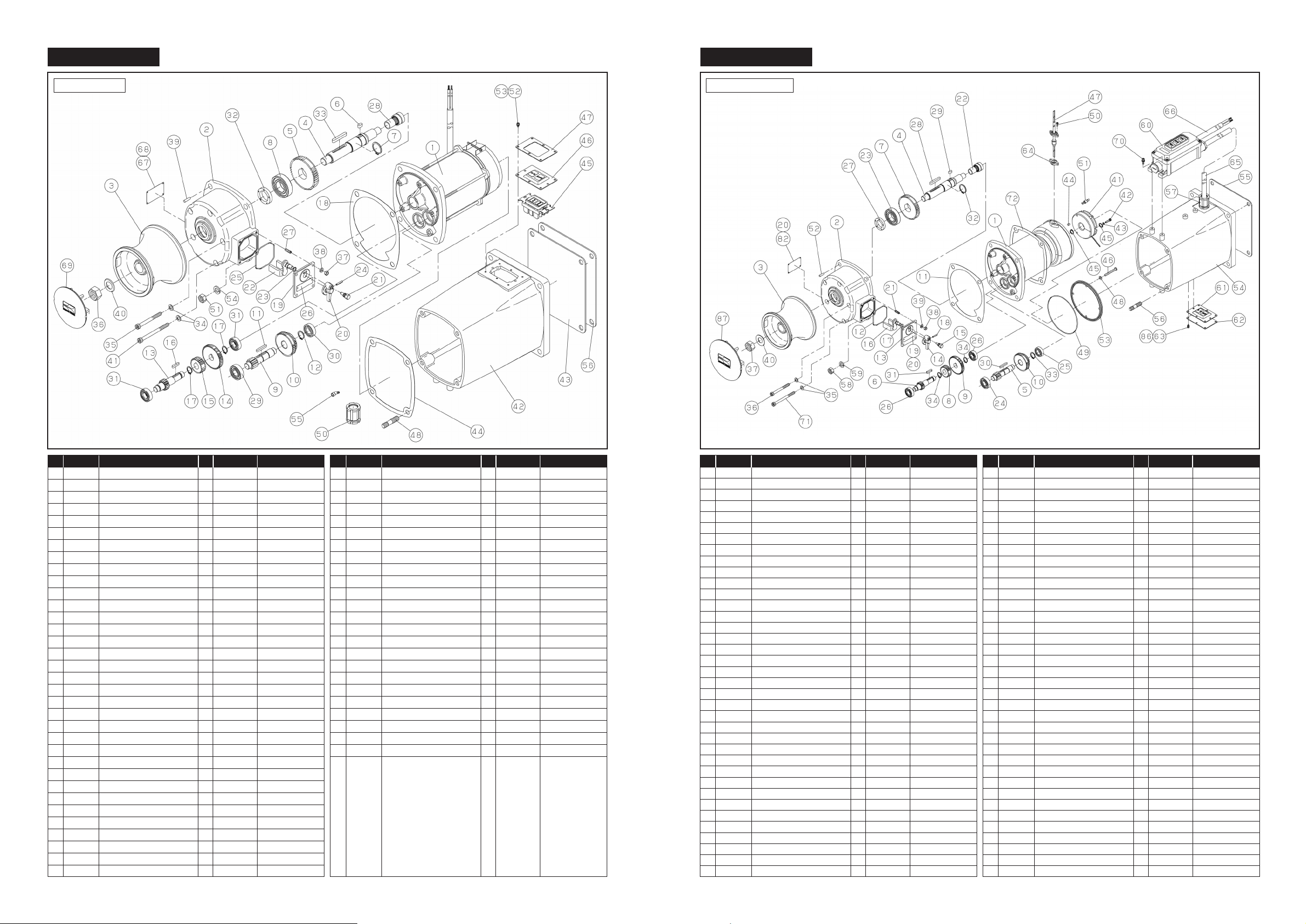

(2) CONNECTING METHOD

Open the upper cover of the push-button switches, then the terminals blocks T,S,R,W,U and V are exposed as shown in the

above drawing.

1) Connect R terminal block of the push-button switch (the switch in the following text) with red lead wire of the motor.

2) Connect S terminal block of the switch with yellow lead wire of the motor.

3) Connect T terminal block of the switch with black lead wire of the motor.

4) Connect V terminal block of the switch with green lead wire of the motor and also connect the wire from V terminal block of

the switch to the wire from negative (-) side of the battery.

5) Connect U terminal block of the switch with blue lead wire of the motor.

6) Connect the wire from W terminal block of the switch with the wire from positive (+) side of the battery.

7) Insert a safety breaker into the wiring from the lead wires of the motor to the battery.

How to connect

You will find terminal blocks T, S, R, W, U, and V as shown in figure II when opening the push button switch cover.

(1) Connect terminal block R of the push button switch (hereafter referred to as "switch") using a black motor lead wire.

(2) Connect terminal block S using a red motor lead wire.

(3) Connect terminal block T using a black (white) electromagnetic break lead wire.

(4) Connect terminal block V using both a white (black) electromagnetic break lead wire and white electric wire from the positive

side of the battery.

(5) Short-circuit terminal blocks U and W and connect terminal block U with a black electric wire from the negative side of the battery.

(6) Install a safety breaker in the electric wire from the motor lead wire to the battery. If you press the positive side of the switch,

the roller operates clockwise from the roller side; and if you press the negative, it does counterclockwise.

(6) Avoid as much as possible using an electric wire over 10m long. If necessary for use, use a wire with a diameter of 8.0mm2or more.

(7) Connect firmly between crimp terminals using screws and nuts. Loose connections may generate heat and result in burnout.

3 4

WRITING

Magnet motor type

Simultaneous use of both positive and negative rotation

RES-5524LB , RES-7524

RES-4024

*Since RES-4024 does not have a break,

wiring for the electromagnetic break lead wire can be omitted.

WHEN USED FOR BOTH FORWARD AND REVERSE TURN

REL-2512(L) .RES-2512(L) .4024 A view of the push-button switch with is upper cover removed.

Note:

1. (R)-(T) (*)-(V) is also available for electromagnetic break cord connection.

2. Short-circuit between switches (W) and (U).

Red

Black

Black

White

White

Positive (+) side

Negative

(-) side

Black

Battery

T

V

R

SV

VU

U

Load

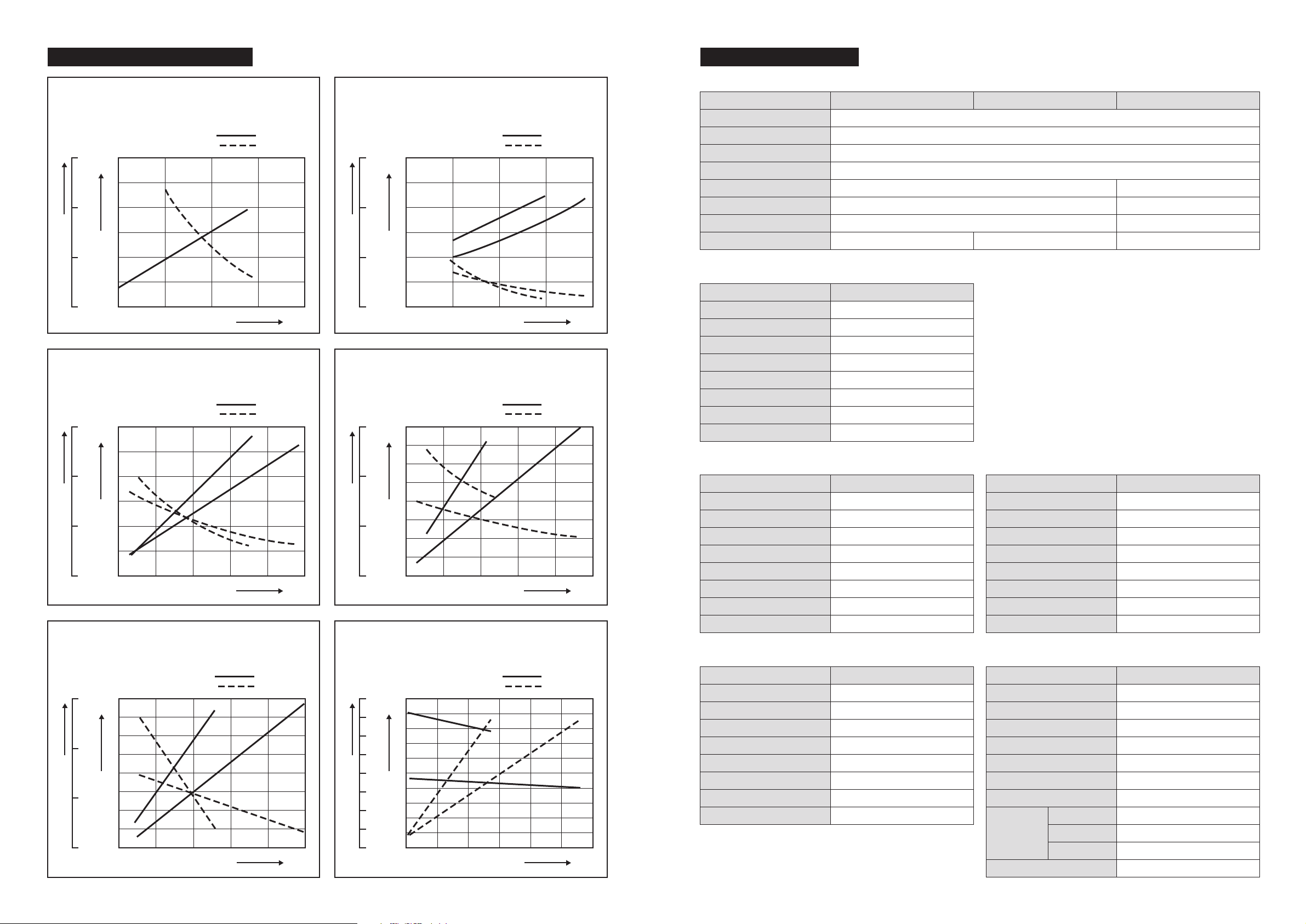

Breaking current

200kg

40A

400kg

60A

600kg

80A

Load

Shut-off current

RES-4012

90kg (100rpm)

180kg (50rpm)

60A

130kg (100rpm)

260kg (50rpm)

80A

Load

Breaking current

200kg

40A

400kg

60A

600kg

80A

(See the performance curve for more details.)

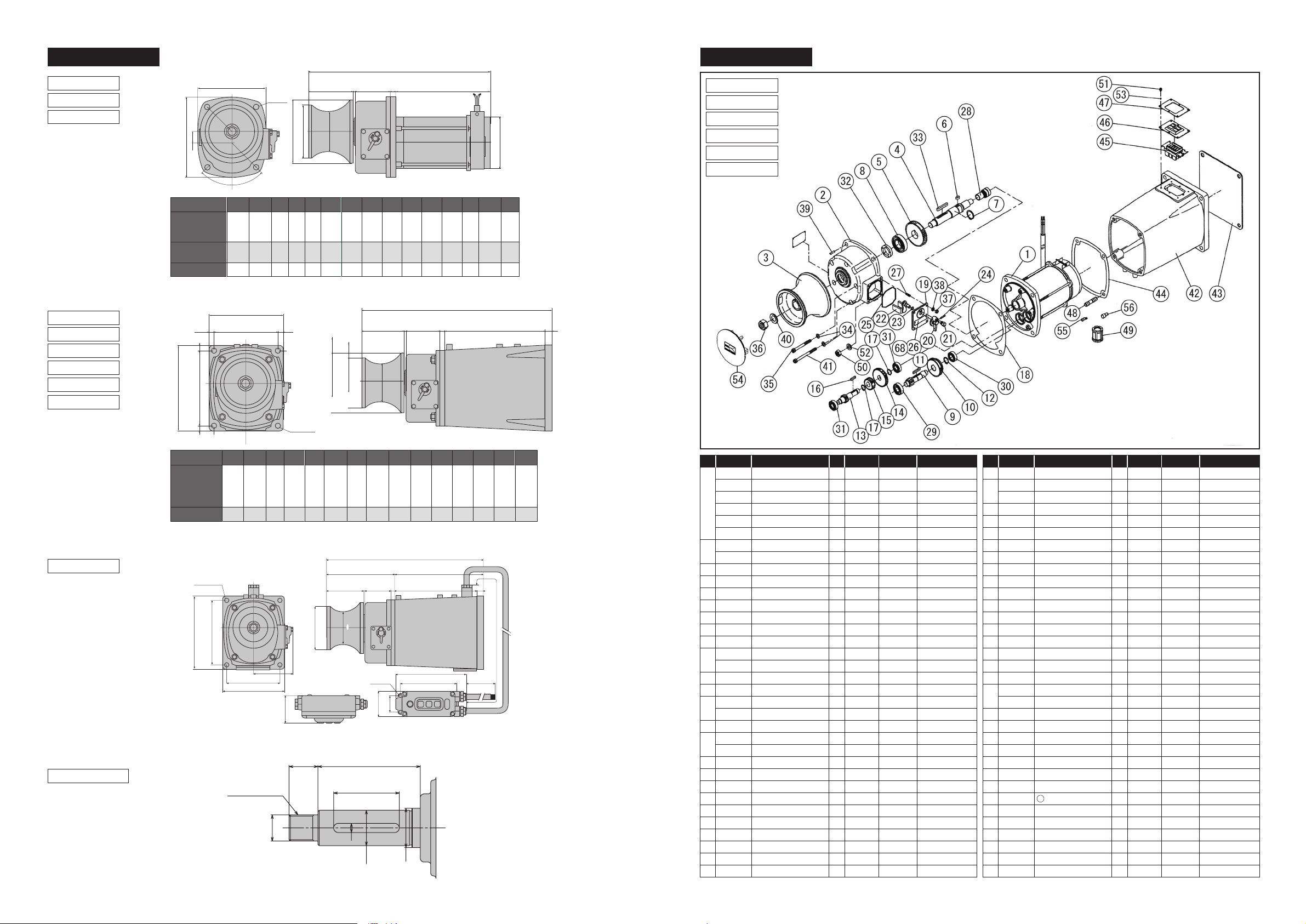

Lead wires

of the motor

Black

Black

White

White

Safety breaker

Positive

(+) side

Negative

(-) side

Battery

1

2

3

4

5

1 Black

Green

Blue

Red

Yellow

2

3

4

5

Lead-wire for

Electromagnetic Brake

Lead-wire for Motor

Motor (Black) - Switch

Motor (Black) - Switch

- Switch

- Switch

Battery - Switch

Battery - Switch

Switch - Switch

R

R

V

T

V

U

U

Safety Breaker