3 4

ExternalOptions

forSWL

SWLZ

Robotic

HandChanger

SWL

RoboticHandChanger modelSWL Features

SelectionConditions

ReferenceDocument

Accessories

ExternalOptions

Cautions

CrossSection

ActionDescription

ModelNo.

Indication

External

Dimensions

Specifications

PerformanceCurve

CrossSection

MasterCylinder(SWL

□

0-M)

ToolAdapter(SWL

□

0-T)

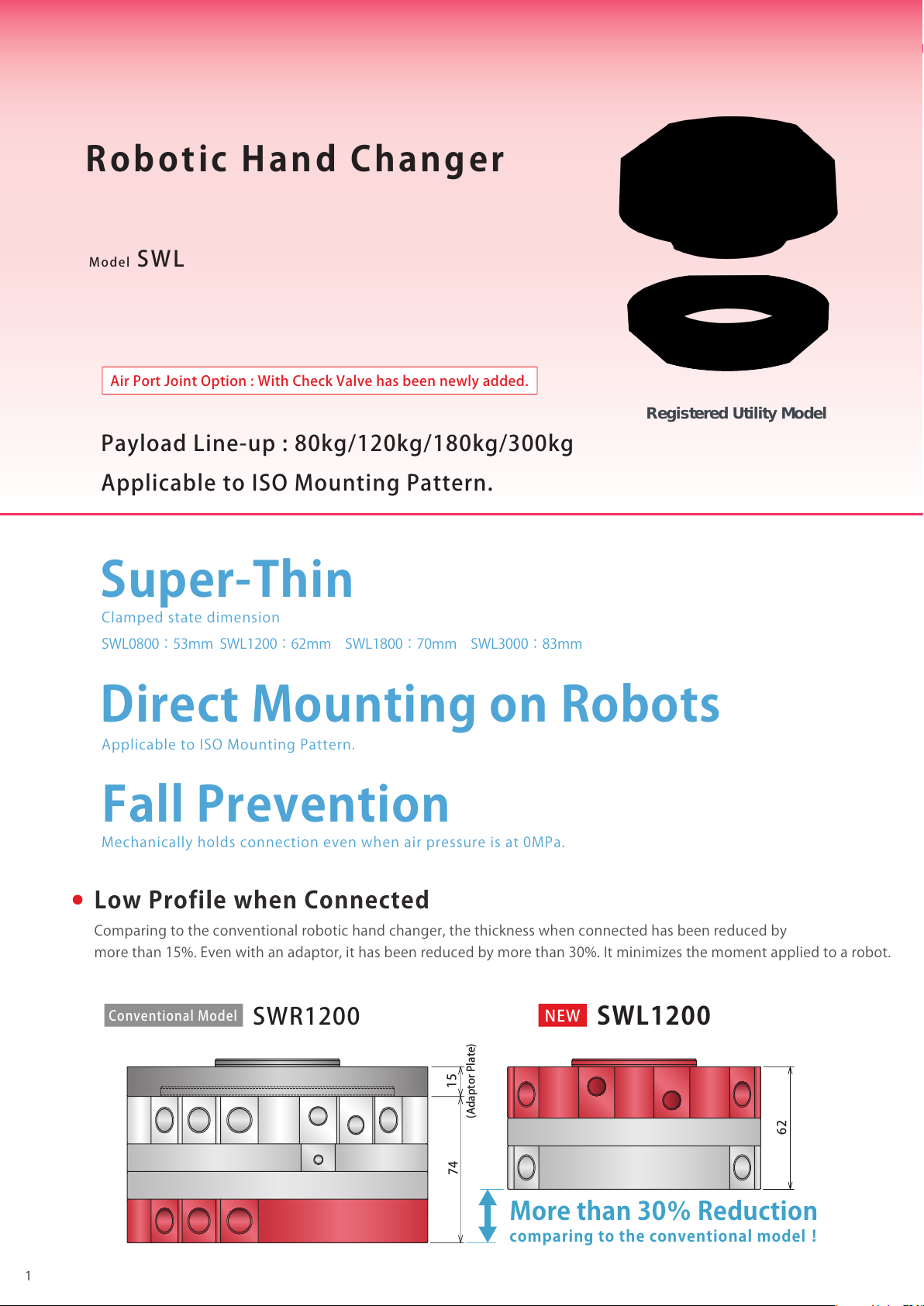

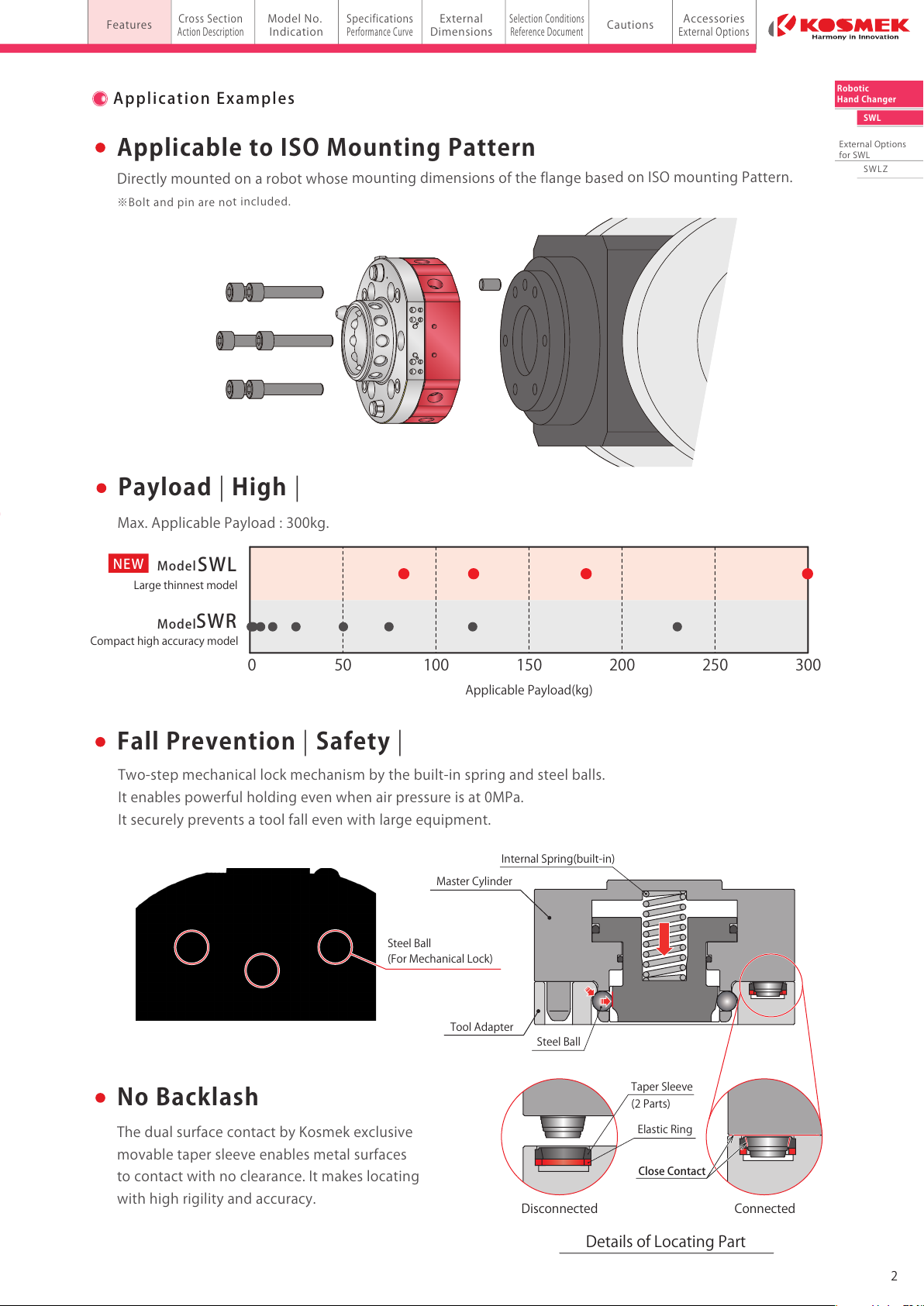

DisconectedState(ReleasedState)ConnectedState(LockedState)

ActionDescription

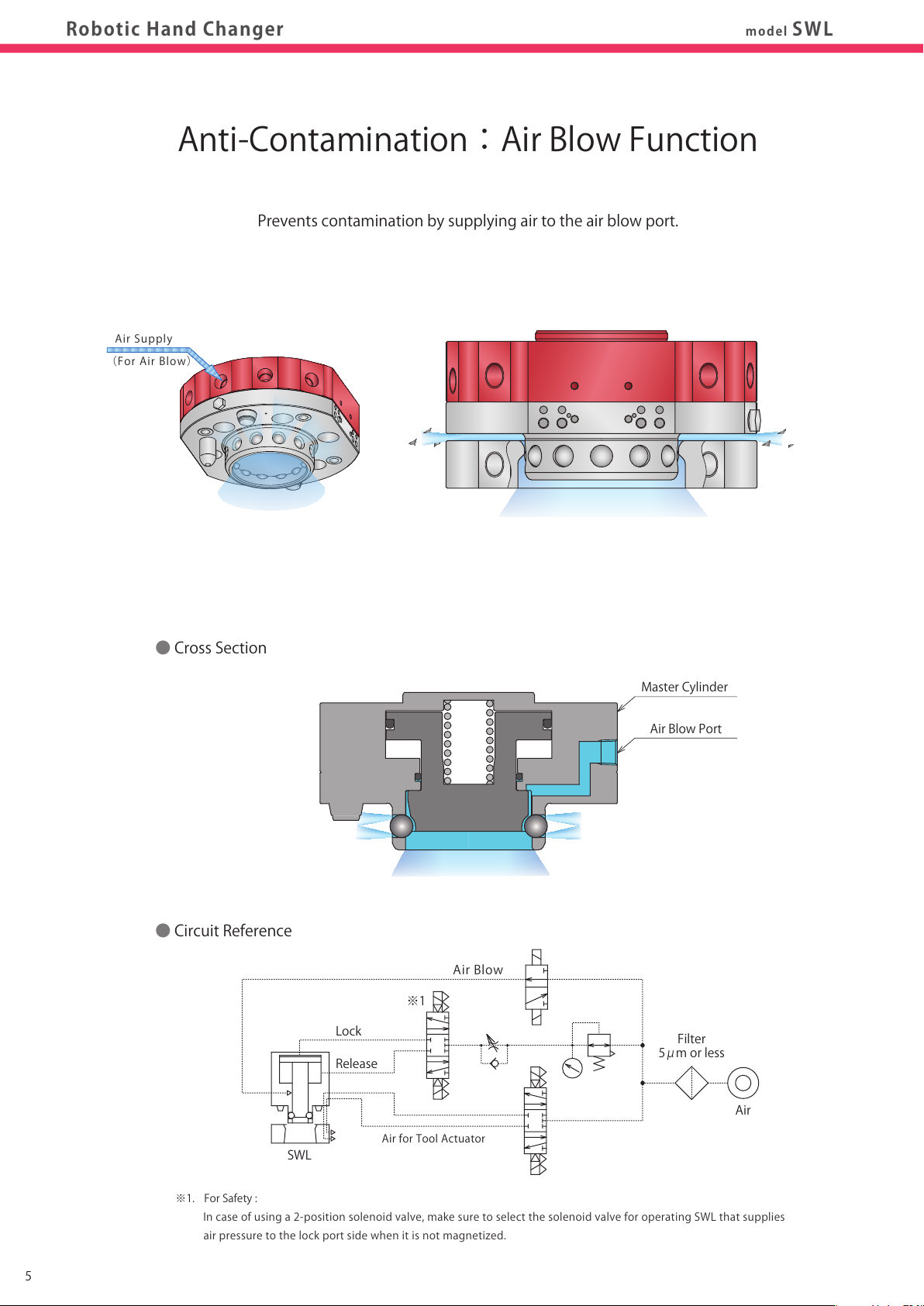

AirBlowPort

RoughGuide

SeatingConfirmationPort

LockAirPort

Locatingpart(2parts)

TaperSleeve(2parts)

ElasticRing

ReleaseAirPort RobotSide

Release

Air

SteelBall

InternalSpring

SteelBall

Nomoveback

StraightSurface

PistonRod

Lock

Air

HandSide

Supplyairtothelockport.Thepistonrodwillbepulleddownwith

pistonthrustandaninternalspring,andthetooladapterwillbe

pulledtotheseatingsurfacebythesteelballs.Whenthetool

adapterispulled,thelocatingpartcontactsthetaperedsurface,

andlocatingiscompleted.

APart

Material:StainlessSteel

(HighHardnessbyHeatTreatment)

Material:Duralumin

AirBlow-outHoleforSeatingConfirmation

Whenlockairpressureislost,mechanicallockmechanismis

activatedandpreventsatoolfall.

Mechanicallockmechanismenablesholdingforcetobe

5timesoftheallowableweightevenwhenairpressureisat0MPa.

APart:MechanicalLockMechanism

Tool

Adapter

Piston

Rod

MechanicalLockMechanism

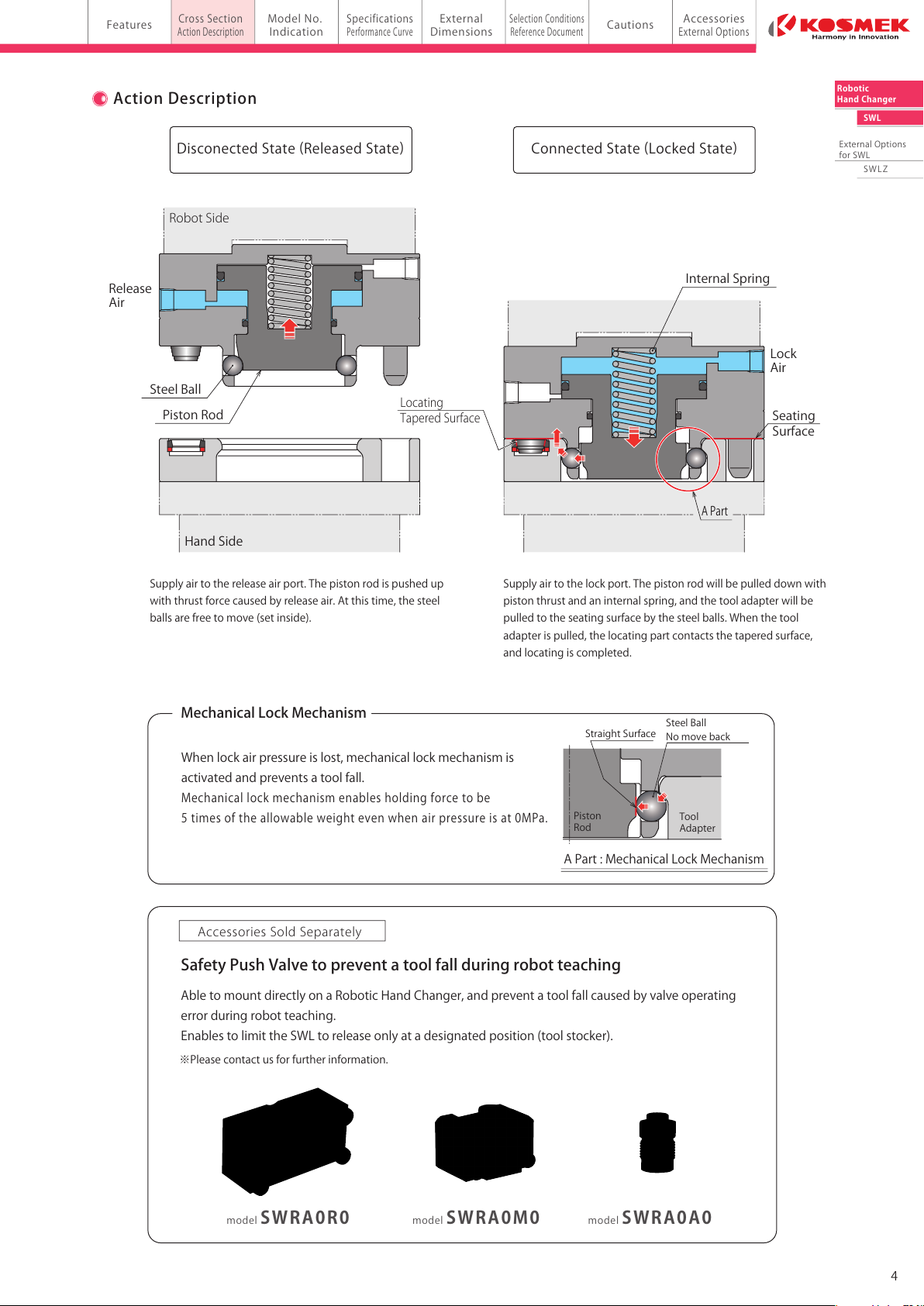

SafetyPushValvetopreventatoolfallduringrobotteaching

AirPort(4ports)

AirPort(4ports)

Seating

Surface

AbletomountdirectlyonaRoboticHandChanger,andpreventatoolfallcausedbyvalveoperating

errorduringrobotteaching.

EnablestolimittheSWLtoreleaseonlyatadesignatedposition(toolstocker).

※Pleasecontactusforfurtherinformation.

modelSWRA0M0modelSWRA0R0 modelSWRA0A0

Locating

TaperedSurface

Supplyairtothereleaseairport.Thepistonrodispushedup

withthrustforcecausedbyreleaseair.Atthistime,thesteel

ballsarefreetomove(setinside).

AccessoriesSoldSeparately

Material:StainlessSteel

(HighHardnessbyHeatTreatment)