4

5. Maintenance and inspection

No special maintenance or inspection is required, but be careful not to let dust in the grease.

Also, check and clean it so that dust and sand do not adhere to the indicator mounted to the

grease checker and the grease nipple. When lubricating from the grease nipple, wipe the grease

nipple and the tip of the grease gun nozzle cleanly before connecting the nozzle to lubricate.

In addition, grease for lubrication is applied to the indicator, and the grease inside is adhered

thinly. It is within the normal specification range that grease is attached to the indicator.

Due to the structure of the indicator, which keeps the internal seal lubricated and operates

smoothly, internal-grease and oil may adhere to the indicator during use (when the indicator

reciprocates). If internal-grease and oil are accumulated on the top of the main unit while

repeating the operation of the indicator, clean it regularly.

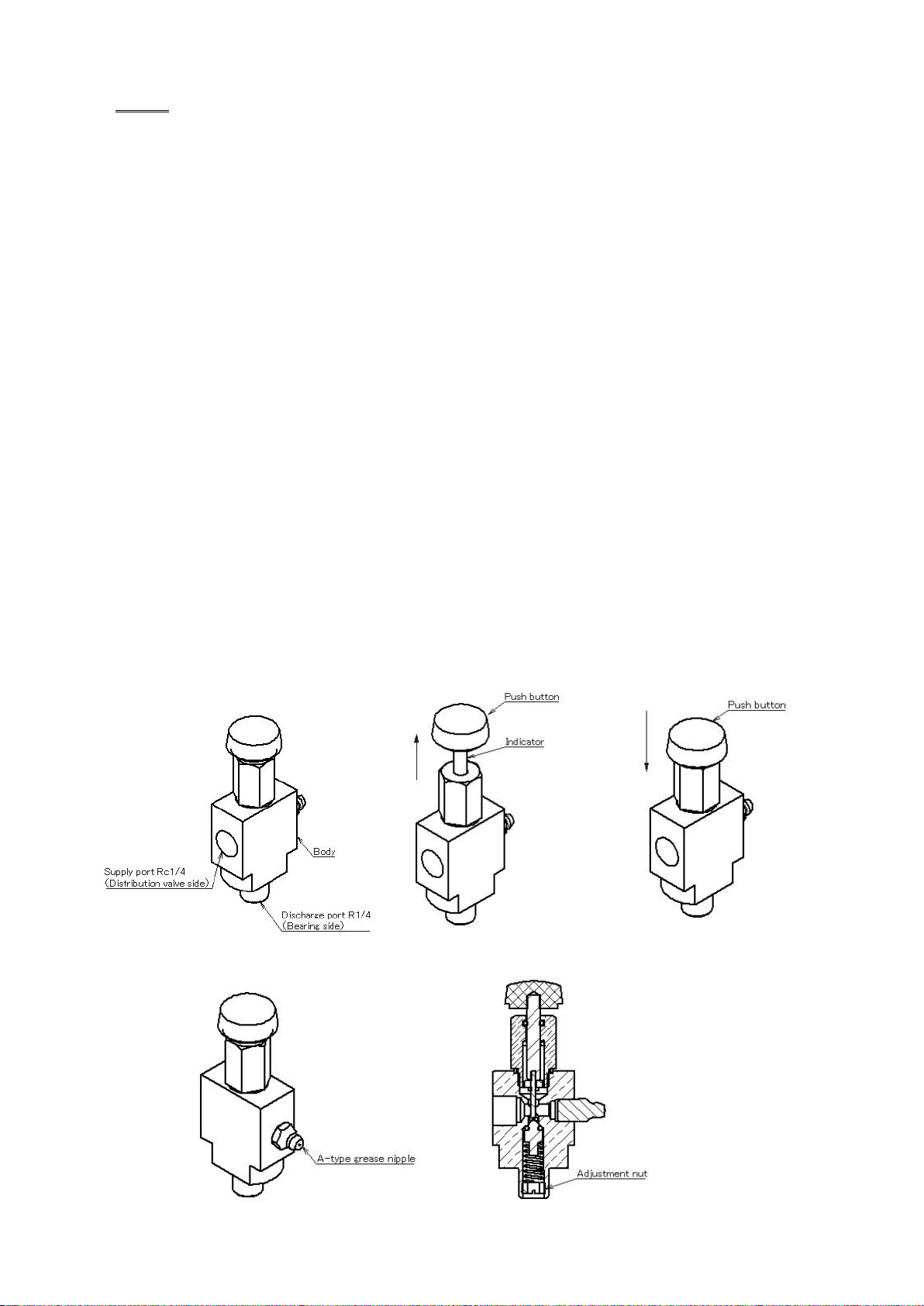

6. Operating method and precautions for use

①If the back pressure from the bearings behind the grease checker is high, it may be pushed

back by the back pressure when the indicator attached to the grease checker is reset. Please

reset after a while, or push down the indicator all the way to release the grease inside.

②If there is a pipe after the grease checker, the pressure loss of the grease will occur

depending on the length and diameter of the pipe. If the pressure loss of the grease pipe is large,

reset it after a while, or push down the indicator to the end to release the grease inside, as in the

case of ①.

③If the indicator is pushed back even after performing (1) or (2), mount a check valve to the

grease checker supply port. By installing a check valve, you can reduce the phenomenon of

pushing back when the indicator attached to the grease checker is reset.

④It is also possible to detect a high pressure condition by installing a check valve at the grease

checker supply port. By the check valve, when the indicator attached to the grease checker is

pushed in, the pushed-in grease will flow to the bearing side. In case it is normal, pushing the

indicator will keep it in that state, but if the bearing is under high pressure due to back

pressure, etc., the indicator will not be pushed in or will be pushed back immediately. In this

state, the back pressure on the bearing side is high, and it can be judged that it is a high

pressure state.

⑥While the grease checker is in use (when the indicator reciprocates), internal grease and oil

will adhere to the indicator, but this is due to the structure in order to maintain the lubricity of

the seal part and to operate smoothly. This is within the normal specification range that grease

is attached to the indicator. (5. Also described in maintenance and inspection)

⑥If the grease checker is not used for a long time, the sliding surface of the indicator attached

to the grease checker and the sliding O-ring may lose lubrication and stick to it. In that case,

turn the indicator push-in button to remove it.