CONTENTS

CONTENTS PAGE

Introduction................................................................................................................................................1

SAFETY INFORMATION

Safety Alert Symbol...................................................................................................................................2

Safety Information ...................................................................................................................................3-5

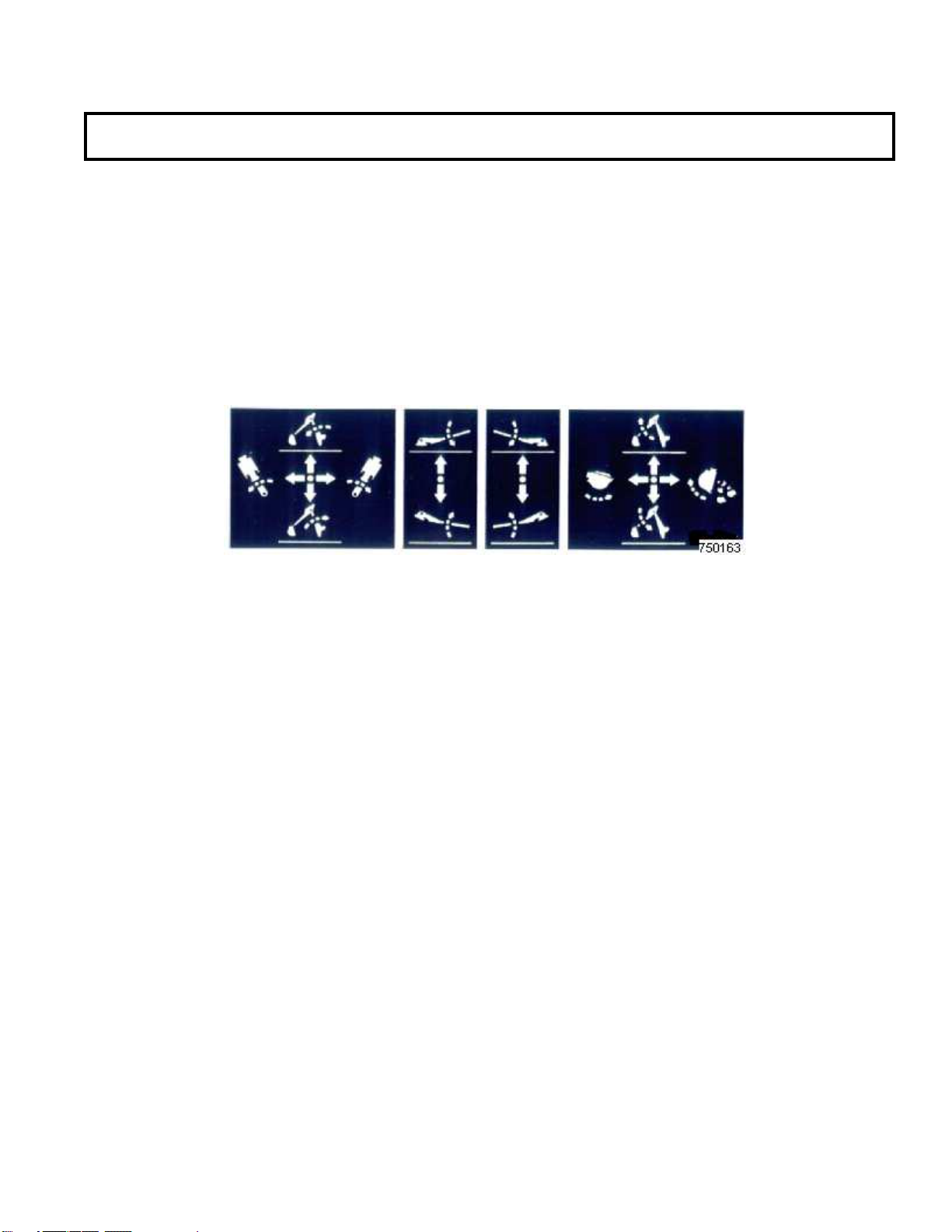

Safety Decals .............................................................................................................................................6

OPERATING INSTRUCTIONS

Operation.................................................................................................................................................7-14

SERVICE AND MAINTENANCE

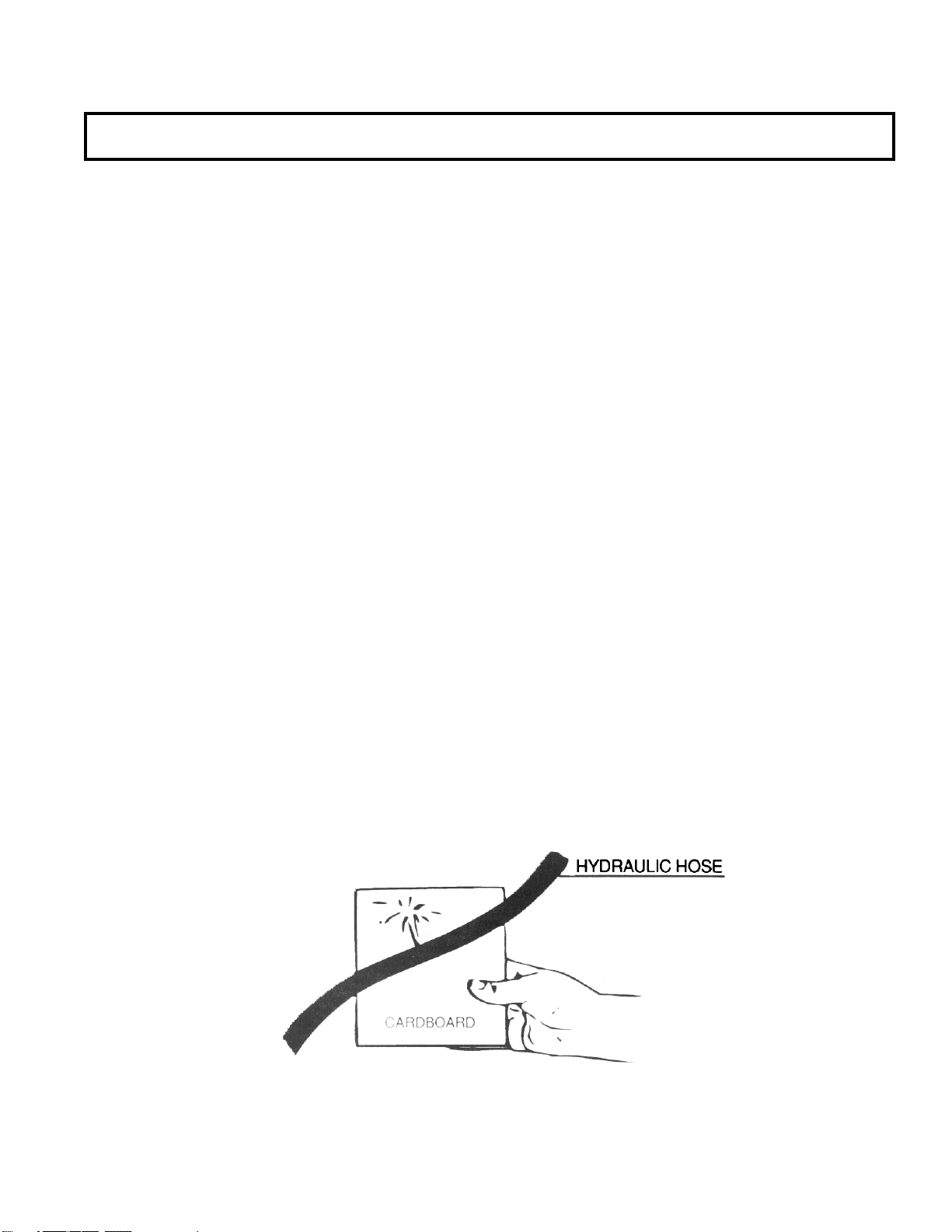

Backhoe Inspection, Service, and Maintenance ....................................................................................15-17

Hydraulic Hose Parts Diagram ................................................................................................................18

Hydraulic Hose Part Schedule..................................................................................................................19

Valve Parts Diagram.................................................................................................................................20

Valve Part Identification Schedule ...........................................................................................................21

In Line Filter Parts Diagram .....................................................................................................................22

Backhoe Main Frame Parts Diagram........................................................................................................23

Backhoe Main Frame Parts Schedule.......................................................................................................24

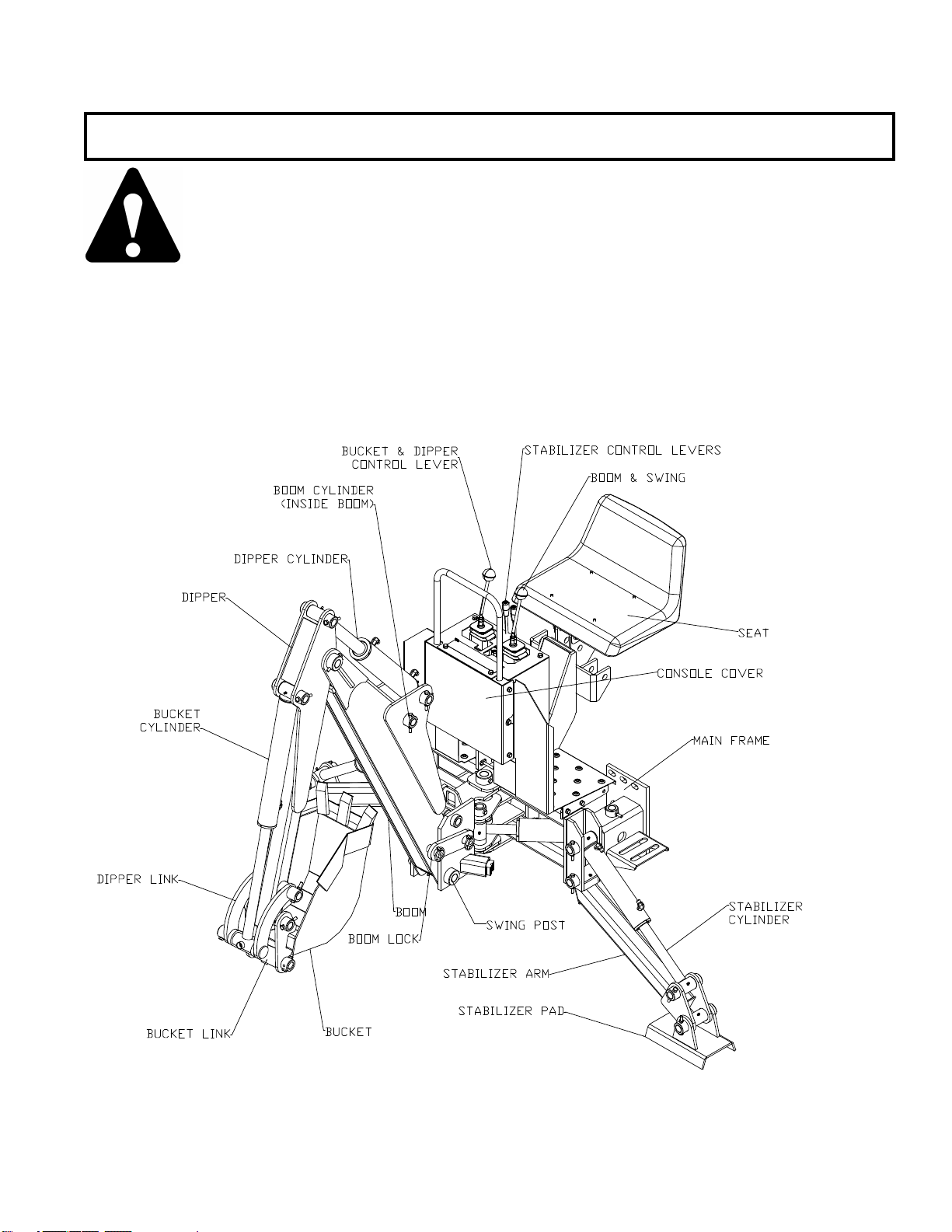

Backhoe Arm Frame Parts Diagram.........................................................................................................25

Backhoe Arm Frame Parts Schedule ........................................................................................................26

Bucket Parts Diagram and Schedule.........................................................................................................27

Bucket Replacement Teeth Diagram and Schedule..................................................................................28

3-Point Mount Diagram and Schedule......................................................................................................29

Drawbar Stabilizer Diagram and Schedule...............................................................................................30

PTO Hydraulic Diagram...........................................................................................................................31

PTO Hydraulic Schedule ..........................................................................................................................32

Torsion Bar Diagram and Schedule..........................................................................................................33

Hydraulic Information ..............................................................................................................................34

2” Cylinder Service Kit Schedule.............................................................................................................35

2 1/2” Cylinder Service Kit Schedule.......................................................................................................36

Hydraulic Cylinder Part Diagram.............................................................................................................37

Piston and Gland Service Diagram...........................................................................................................38

LIMITED WARRANTY INFORMATION

Limited Warranty...................................................................................................................................39-41

TORQUE SPECIFICATIONS

Torque Specifications ...............................................................................................................................42