3KR Electrical Defrost Unit Coolers (PN E108318_S)

TABLE OF CONTENTS

1 RECEIPT OF EQUIPMENT................................................................................................................................................ 5

1.1 INSPECTION............................................................................................................................................................... 5

1.2 LOSS OF GAS HOLDING CHARGE........................................................................................................................... 5

2 LOCATION RECOMMENDATIONS................................................................................................................................... 5

3 UNIT MOUNTING............................................................................................................................................................... 6

4 DRAIN LINE ....................................................................................................................................................................... 8

5 REFRIGERATION PIPING ................................................................................................................................................. 8

6 REFRIGERANT DISTRIBUTOR NOZZLES ...................................................................................................................... 9

7 EXPANSION VALVE ........................................................................................................................................................ 12

8 WIRING ............................................................................................................................................................................ 15

8.1 AIR DEFROST MODELS WIRING DIAGRAMS........................................................................................................ 16

8.2 ELECTRIC DEFROST MODELS WIRING DIAGRAMS............................................................................................ 18

8.3 GAS DEFROST MODELS WIRING DIAGRAMS...................................................................................................... 24

9 SEQUENCE OF OPERATION ......................................................................................................................................... 26

9.1 MODELS H - 3 PIPE HOT GAS WITH ELECTRIC PAN HEAT AND P - 2 PIPE KOOL GAS WITH

ELECTRIC PAN HEAT .............................................................................................................................................. 27

9.2 MODELS G - 3 PIPE HOT GAS WITH GAS PAN HEAT AND K - 2 PIPE KOOL GAS WITH GAS PAN HEAT....... 28

9.3 DUAL SPEED MOTOR SEQUENCE OF OPERATION ............................................................................................ 30

9.4 VARIABLE SPEED MOTOR SEQUENCE OF OPERATION..................................................................................... 30

9.5 VARIABLE SPEED MOTOR WITH SYSTEM 450 - SEQUENCE OF OPERATION ................................................. 30

9.6 INTERLOCKING SINGLE COMPRESSOR UNIT WITH KRACK COIL.................................................................... 31

10 PRE-STARTUP ................................................................................................................................................................ 33

11 REPLACEMENT PARTS ................................................................................................................................................. 34

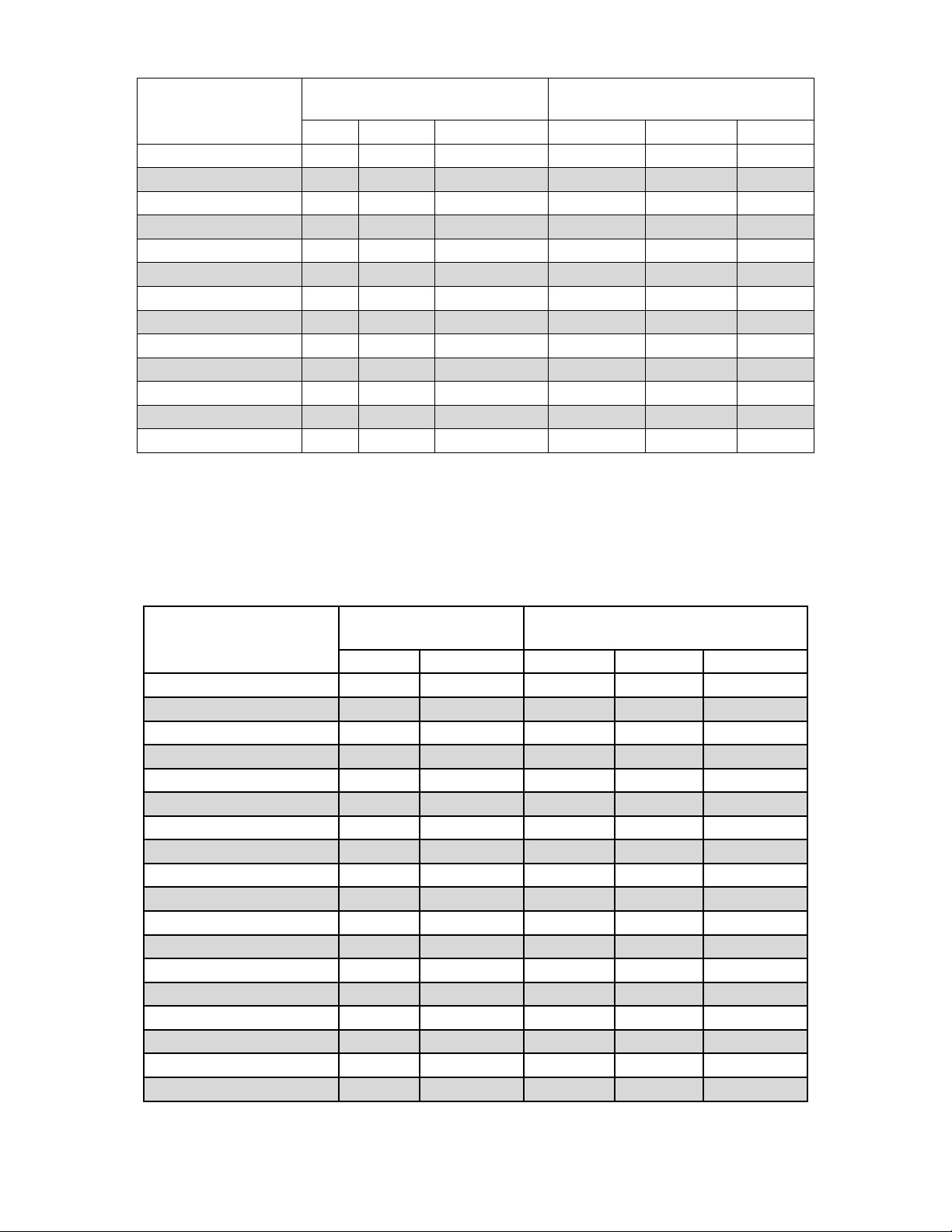

TABLES

TABLE 1A. Electric Defrost Unit Dimensions and Connection Sizes ..................................................................................6

TABLE 1B. Gas Defrost Unit Dimensions and Connection Sizes........................................................................................7

TABLE 1C. Air Defrost Unit Dimensions and Connection Sizes..........................................................................................7

TABLE 2A. Air Defrost Models Distributor Nozzle Selections............................................................................................10

TABLE 2B. Electric Defrost Models Distributor Nozzle Selections ....................................................................................10

TABLE 2C. Gas Defrost Models Distributor Nozzle Selection........................................................................................... 11

TABLE 7A. Recommended Expansion Valves for Air Defrost Models...............................................................................12

TABLE 7B. Recommended Expansion Valves for Electric Defrost Models .......................................................................13

TABLE 7C. Recommended Expansion Valves for Gas Defrost Models ............................................................................14

TABLE 8. Motor and Defrost Electrical Information – Electric Defrost...............................................................................15

TABLE 9. Motor and Defrost Electrical Information – Hot Gas Defrost .............................................................................15

TABLE 10 Replacement Parts...........................................................................................................................................35

FIGURES

FIGURE 1 Unit Dimensions ................................................................................................................................................6

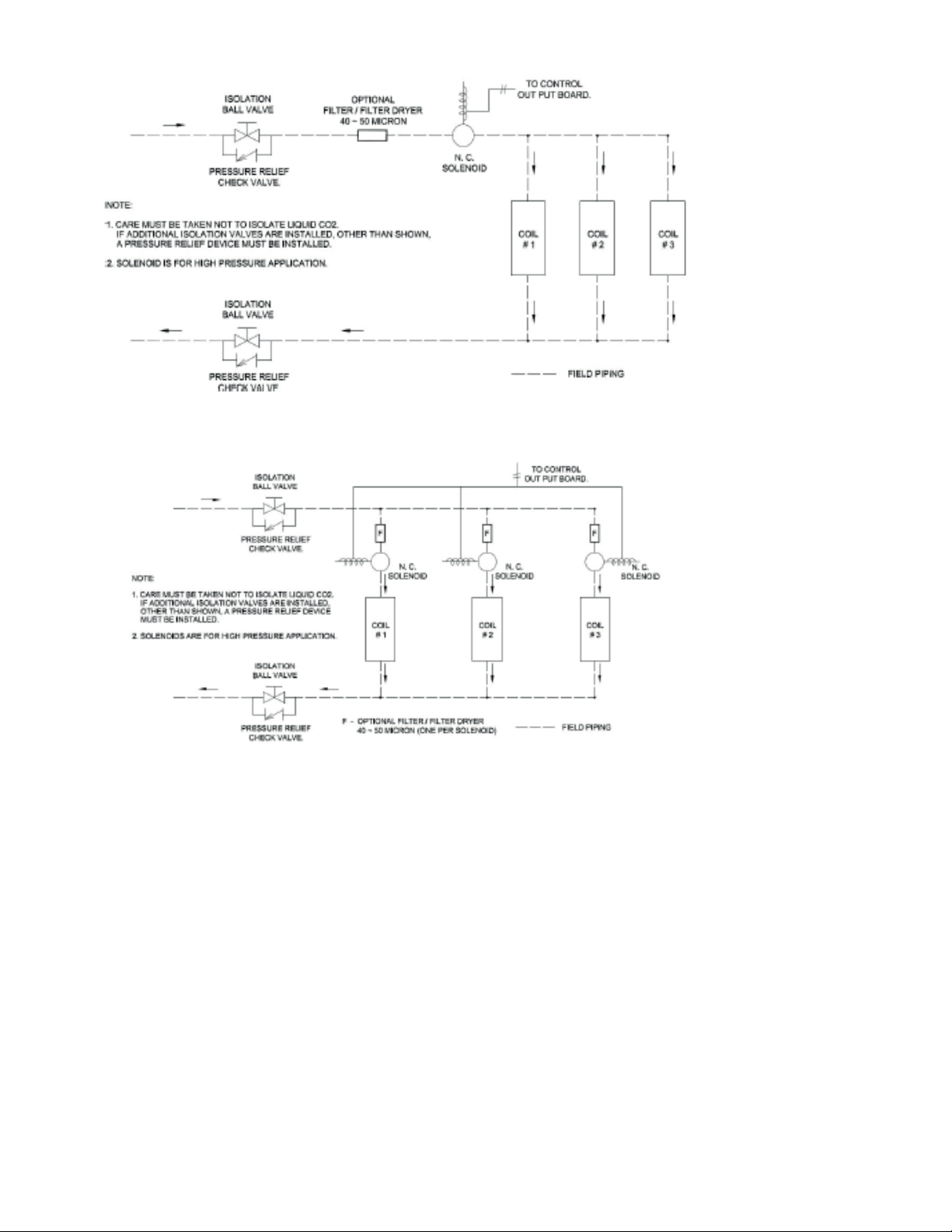

FIGURE 2 Multiple Unit Coolers Controlled By a Single Solenoid ......................................................................................9

FIGURE 3 Multiple Unit Coolers Controlled By Multiple Solenoids.....................................................................................9

FIGURE 4A Air Defrost Wiring Diagrams for Motor Type B...............................................................................................16

FIGURE 4B Air Defrost Wiring Diagram for Motor Type V ................................................................................................16

FIGURE 4C Air Defrost Wiring Diagram for Motor Type D ................................................................................................16

FIGURE 4D Air Defrost Wiring Diagram with Timer - Motor Type B..................................................................................17

FIGURE 4E Air Defrost Wiring Diagram with Timer - Motor Type V……………………. ....................................................17

FIGURE 4F Air Defrost Wiring Diagram with Timer - Motor Type D ..................................................................................17

FIGURE 5A Electric Defrost System with Timer Wiring - Motor Type B ............................................................................18

FIGURE 5B Electric Defrost System with Timer Wiring - Motor Type V ............................................................................18

FIGURE 5C Electric Defrost System with Timer Wiring - Motor Type D............................................................................19

FIGURE 6A Electric Defrost with Timer and Defrost Contactor Wiring - Motor Type B ....................................................19

FIGURE 6B Electric Defrost with Timer and Defrost Contactor Wiring - Motor Type V ....................................................20