Revision 4 Swing Auger Mover Page | 8

Kramble Industries Inc. is not responsible or liable for indirect, special, or consequential damages arising out of or in connection

with the use or performance of the product or other damage with respect to any economic loss, loss of property, loss of revenue

or profit, or costs of removal, installation, or reinstallation.

General Operation

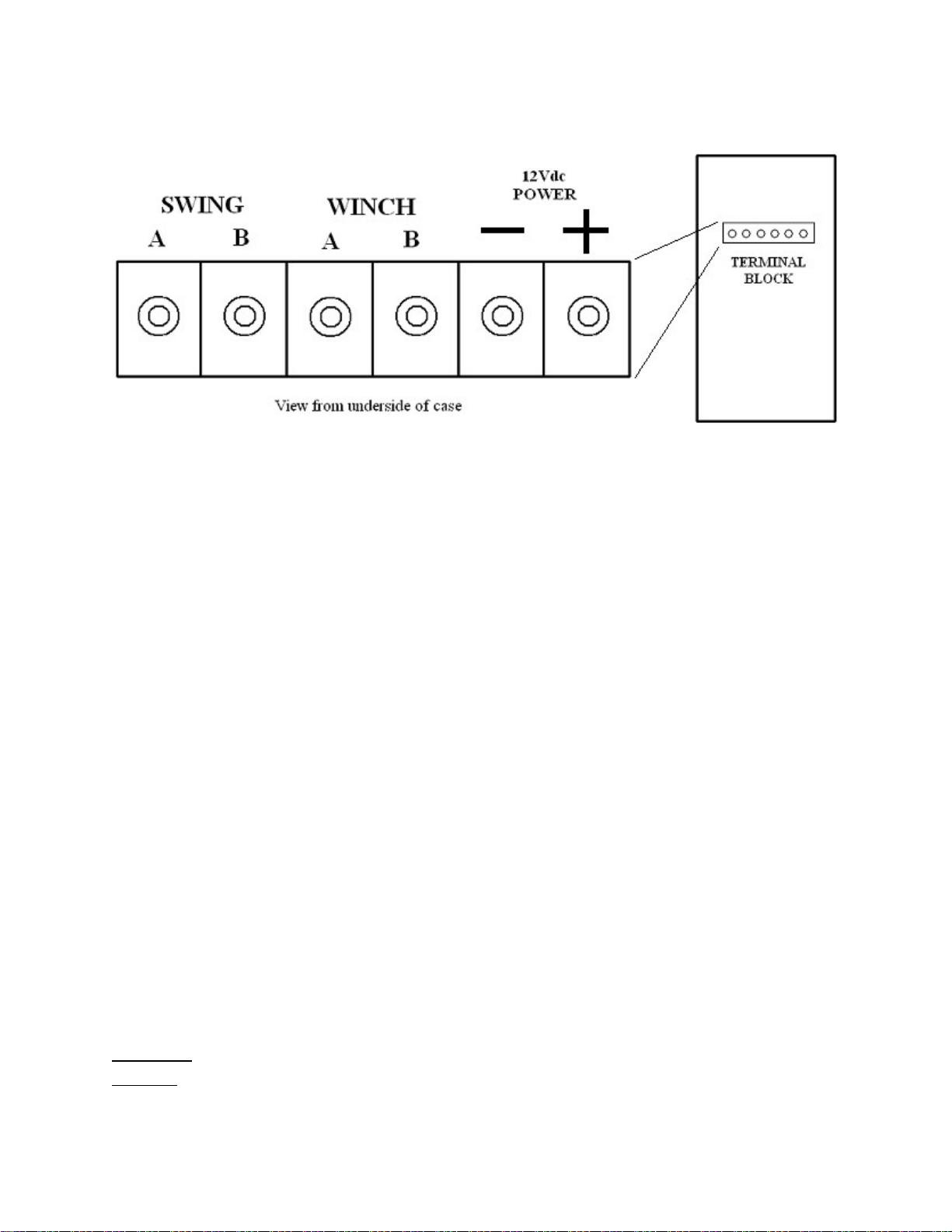

Control Console

The Control Console contains the radio Receiver and power control circuits. The Control

Console is equipped with a Master Power On/Off switch on the outside of the case. When the

switch is ON, the Red LED should be lit indicating normal operation. Press and release to turn

On and Off.

Each of the Swing Auger Drive and Winch may be operated independently from the Control

Console by pressing the desired momentary switch. The Green “Output” LED will come on and

the selected device will operate.

The Control Console also has built-in fault status indicators. For ease of troubleshooting, if a

“low voltage” status occurs to the Control Console, the green Fault States Indicator will blink

approximately twice per second. Check all connections to ensure they are clean and tight. Make

sure that the tractor battery is fully charged, and the engine is running. If a “control circuit high

temperature” status occurs the green Fault States Indicator will flash rapidly, blinking

approximately four times per second. Allow the unit to cool before resuming operation.

Each Swing Auger Mover has its own RF receiver located in the control console, which is

channel selectable to operate in multi-component environments e.g. remote control trailer

chutes on Channels 1 & 2, and the Swing Auger Mover on Channel 3. The user can select the

desired channel using the 2-position dip-switch. All Swing Auger Movers are set to Channel 1 at

the factory.

Auxiliary Output (option)

The Control Console Auxiliary Output provides a remote control power output capable of

delivering 10A (120 watts). This feature is intended for the operation of a remote control light

for illuminating the work area when approaching at night, or for operation of a camera or other

device. The output can be activated and deactivated from the transmitter by pressing the

centre button on the RF transmitter (marked AUX), or from the Control Console by pressing the

two “Aux” control buttons on the face of the Control Console simultaneously. The auxiliary

output is protected by a thermal fuse that automatically resets when cooled. The auxiliary

output is automatically shut off when the fuse trips to prevent a repeating cycle of the fuse

tripping and resetting and must be reactivated using the transmitter or Console controls.