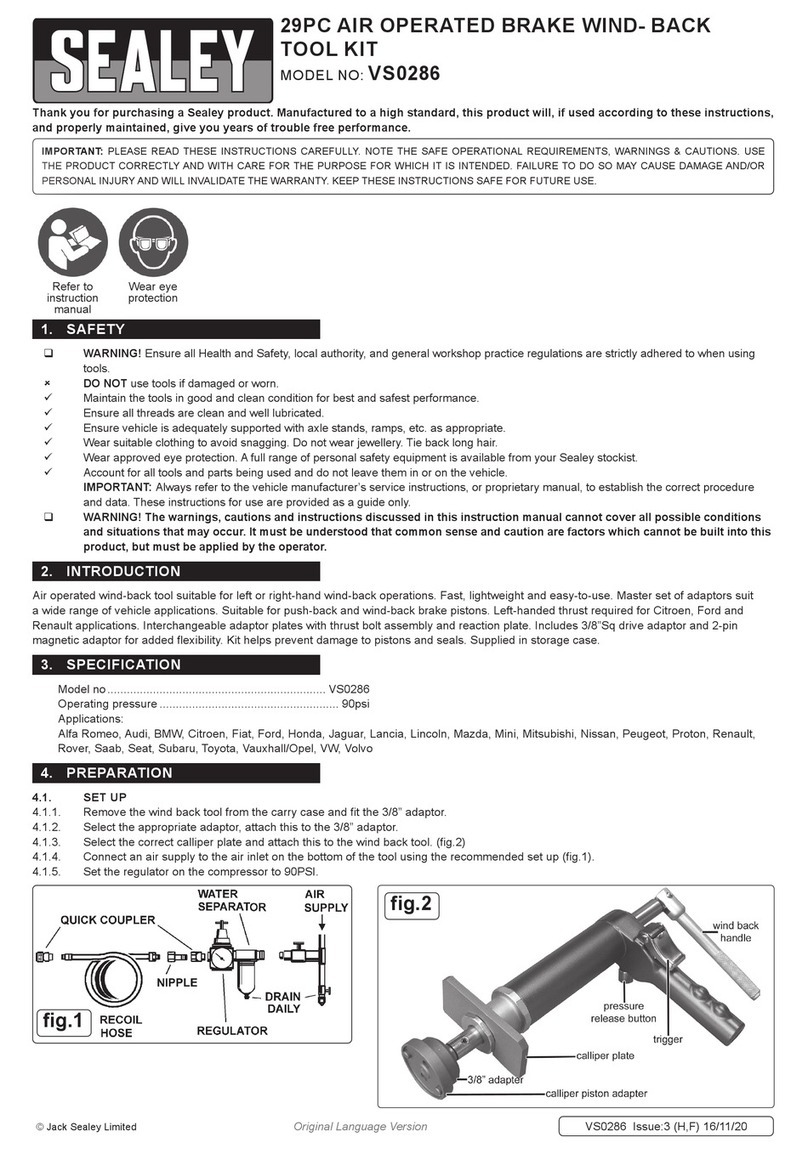

3.1. Identify the chock mounting points as shown in fig.3. The mounting holes are square to enable the use of coach bolts, having

a short square shank behind the head which prevents the bolt from rotating whilst the fixings are tightened.

3.2. Permanent Indoor/Outdoor Installation. Choose the installation site carefully so that there is good access to both insert the

motorcycle, and remove it, from the chock. When mounting indoors, ensure that the motorcycle and chock do not become a hazard to

people or indoor vehicles such as fork lift trucks. Use anchor bolt fixings to secure the chock to a solid concrete surface.

3.3. Installation for transportation. When used for the transport of motorcycles, the base must be firmly bolted to the floor of a trailer or

van. If mounting to a trailer or other vehicle, ensure that the floor is strong enough to take the weight of the motorcycle/s plus

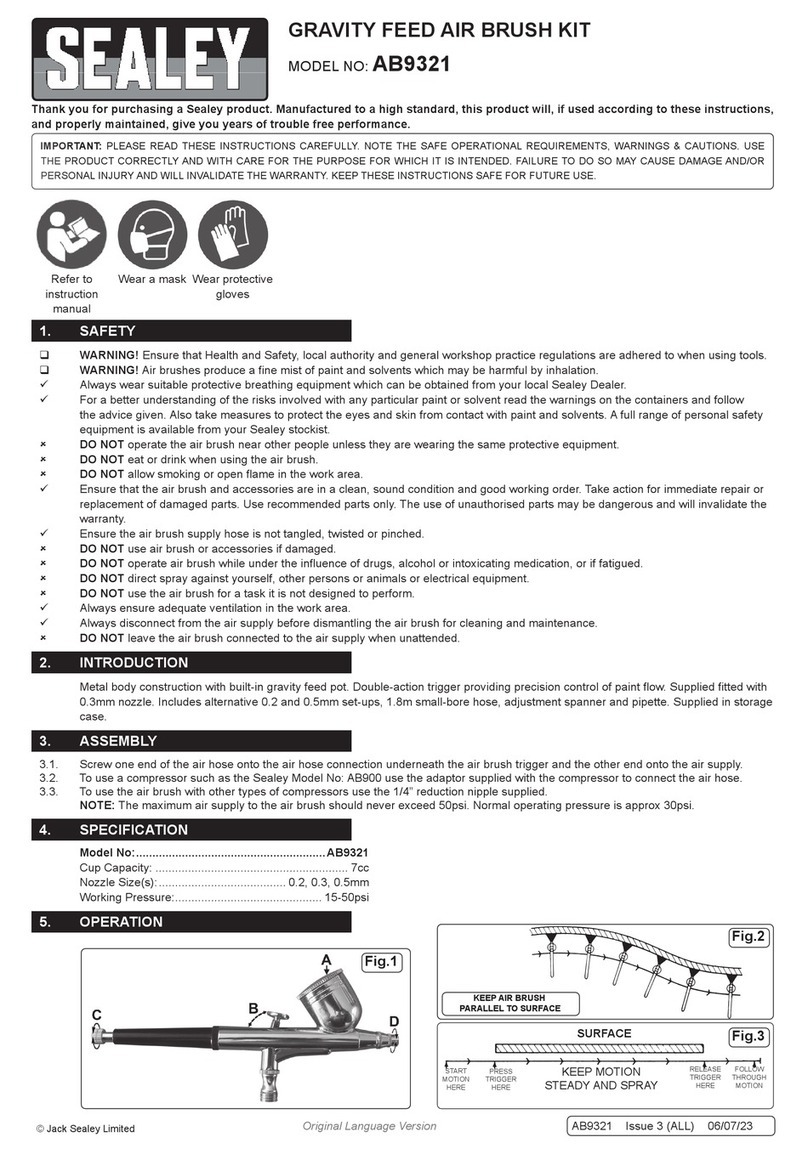

the chock/s. The chock is secured to the base by means of the four wing bolts and spring washers (fig.5). When using the chock for

transportation purposes, the front wheel of the motorcycle must be securely strapped to the chock utilising the strap gap indicated in

fig.4. For additional security, consideration should also be given to securing the rear wheel as well.

4.1. Set hinged cradle to correct height. Ascertain the size of the motorcycle's front wheel in order to set the hinged cradle part of the

chock at the correct height (fig.4). Position 1 is for larger wheels up to 535mm in diameter. Position 3 is for smaller wheels down

to 430mm. Position 2 is for sizes in between the stated limits.

4.2. Using a 17mm spanner, remove the nuts from the hinge bolts and remove the bolts. Position the cradle at the required height and

re-insert the bolts. Screw the nuts back onto the bolts and tighten them to the point where the nuts just start to grip. Now back the

nuts off slightly so that the cradle can pivot freely.

4.3. Positioning the front wheel of the motorcycle into the cradle. With the cradle in the open position as shown in fig.3, line the

motorcycle up with the chock.

4.4. Push the motorcycle firmly into the chock so that the front tyre is held by the tapered part of the chock loop.

4.5. As the weight of the wheel passes over the inner loop of the cradle, it will cause the cradle to flip up and support the rear of the tyre as

shown in fig.1.

4.6. Check that the bike is stable within the chock before leaving it. If the wheel is loose in the chock, move the cradle up to the next

position. If the wheel is riding too high, move the cradle down so that the bottom of the tyre is in contact with the baseplate.

4.7. Removing bike from cradle. More effort will be required to remove the bike from the cradle. Ensure that the space into which the bike

will move is free from obstructions and people.

5.1. When the chock is not in use, leave it in the open position.

5.2. Keep the chock clean and wipe off any oil or grease.

5.3. Before each use check all parts. If any part of the chock is

damaged or defective, remove the chock from service and take the

necessary action to remedy the problem.

5. MAINTENANCE

3. INSTALLATION

4. OPERATING INSTRUCTIONS

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

01284 757500

01284 703534

sales@sealey.co.uk

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

IP32 7AR

www.sealey.co.uk

Web

email

fig.3 fig.4

Parts support is available for this product. To obtain a parts listing and/or diagram, please log on to

www.sealey.co.uk, email sales@sealey.co.uk or phone 01284 757500.

fig.5

Environmental Protection

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted,

taken to a recycling centre and disposed of in a manner which is compatible with the environment. When the product becomes

completely unserviceable and requires disposal, drain off any fluids (if applicable) into approved containers and dispose of the

product and the fluids according to local regulations.

Original Language Version FPS6.V2 Issue:1 - 23/06/16

© Jack Sealey Limited