N.KO B5 User manual

1

N.KO spol. s r.o. IČO: 26161109

a Member of Richtr Group DIČ: CZ26161109

TÁBORSKÁ 398/22 č.ú.: 6626171001/5500

293 01 MLADÁ BOLESLAV email: [email protected] www.nko.cz

CZECH REPUBLIC TEL: +420 326 772 001

FAX: +420 326 774 279

DUNS:495075462 Výpis z obchodního rejstříku je veden u Krajského obchodního soudu v Praze, oddíl C, vložka75712

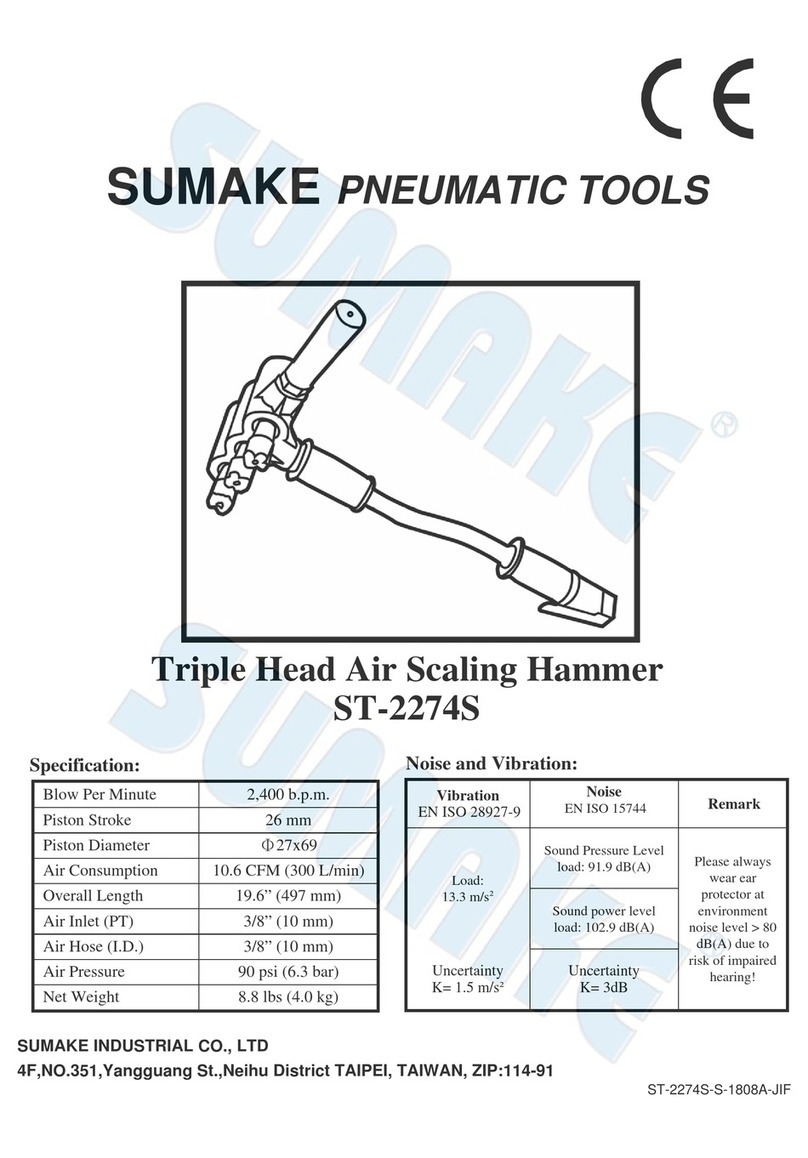

Beveling and Deburring Device B5

obj.č. 25 200

Operation manual

EN

2

General Safety Instructions

Please read this manual carefully and follow all relevant instructions and information.

When using electric tools, always adhere to the following safety instructions in order to prevent electric shock, fire

hazard and risk of injury:

Prior to every use, check device, power cable and plug! Do not use device with the switch damaged, when the

device cannot be switched on and off, or when the speed governor of the motor does not work reliably.

Only connect the plug to the power supply with the motor switched off.

Keep the device away from moisture and do not use in moist conditions.

Do not use the device in the proximity of flammable fluids or gases.

Ensure your workspace is well lit.

Always wear safety goggles.

Mind long hair and jewellery. They may become entangled in the rotating motor shaft.

Do not touch the cutter.

The work piece must be held and fixed tightly during the machining process.

Ensure the power supply cable is flat on the ground. Avoid tripping hazards.

Assume a firm stance when working.

Always disconnect from power supply before working on device or motor.

Protect yourself from electric shock.

Avoid physical contact with grounded parts.

Do not overload the device. Secure and ideal operation of the device is possible within the specified range of

performance of the drive motor only.

Do not use the device for purposes other than specified.

Do not misuse the power cable. Never carry the device by the cable. Never pull the cable when disconnecting

the plug from the power supply.

Protect the power cable from heat, oil, gasoline and sharp edges.

Always have damaged devices repaired by a specialist.

3

Unpacking the Device

Please check the packing for intactness and for possible damage by transport. In the case of damage by transport,

please notify the shipping agency immediately. The shipping agency will be liable for any occurring damage by

transport.

Connecting the Device

The device is supplied ready for operation.

Power supply 230V AC, ~6A, 50/60Hz (other countries 110V)

The 1,300 watt motor is equipped with a safety switch. If the plug is disconnected or if a power failure occurs while the

motor is running, the switch toggles to the OFF position.

When changing tools or adding accessories, disconnect the power plug from

the power supply to prevent accidents.

Read the manual carefully.

Specific Safety Instructions

Risk of injury to your hands! Do not reach into the machining zone. Hold the device with both hands!

Always run the cable away from the device and avoid sharp edges.

Risk of injury by hot chips.

Risk of injury by incorrect use!

Never touch tool with the device running.

Always hold device away from body.

Do not carry out overhead work with device.

Wear safety goggles.

Description

The B5 Deburring Device, item no 25200 is intended for deburring operation to inner and outer edges, radii and bores

from 20mm (=10mm radius).

Designed for steel, stainless steel, aluminium, aluminium alloys, brass and plastics machining jobs, for clean visible

edges and for the preparation of weld seams.

Tool-free adjustment of chamfer height.

Handy and powerful.

Triple cutting insert holder.

For industrial and handiwork purposes.

For producing visible edges in plant and

machine construction.

For use in ship building to remove sharp angles and edges in order to avoid paint chipping (corrosion

protection).

Optional:

Adjustable guidance-stop for outer edge Prod.-No.: 25207

25207

4

Specifications

Motor voltage: 230 volts, 50/60Hz

110V for other countries

Power: 1.300 W

Speed: 4.200 to 11.000min-1 with soft start, including thermo protection and overload limiter

Feed: manual

Feed rate: 1-4 m/min, dependant on chamfer width and material quality

Bevel Height and Width

The bevel width is calculated using the following equation: B = H x 1.414

Material and

Chamfer Width (2) mm

60°

45°

Tensile Strength

230V

230V

Steel 400 N/mm²

4

5

Steel 600 N/mm²

3

3

Stahl 800 N/mm²

2

2

Aluminium 250 N/mm²

6

6

Adjusting the bevel width and height

The bevel height can be adjusted using the support plate and is metered by means of the marker on the graduated

collar.

1 = Support plate.

2 = Knurled nut.

3 = Adjusting collar.

4 = Scale.

5 = upper limitation stone

a) Loosen knurled screw (2).

b) Turn support plate (1) until desired bevel height is achieved on graduated collar. The line markings on the scale

indicate the approximate bevel height in millimetres (one marking line is approx. 1mm). Use the markings on the

adjusting collar for fine adjustment. The distance from one marking line to the next corresponds to approx. 0.05mm

of chamfer height.

c) Tighten knurled screw (2).

d) The upper limitation stone (5) limited the bevel width

5

The bottom mark on the scale corresponds to a bevel height of approx. 1mm. It is recommended to

establish the exact chamfer height using a test job.

Graduated Collar:

On assembly, the device is adjusted to zero position. Zero position means a bevel height of 0.

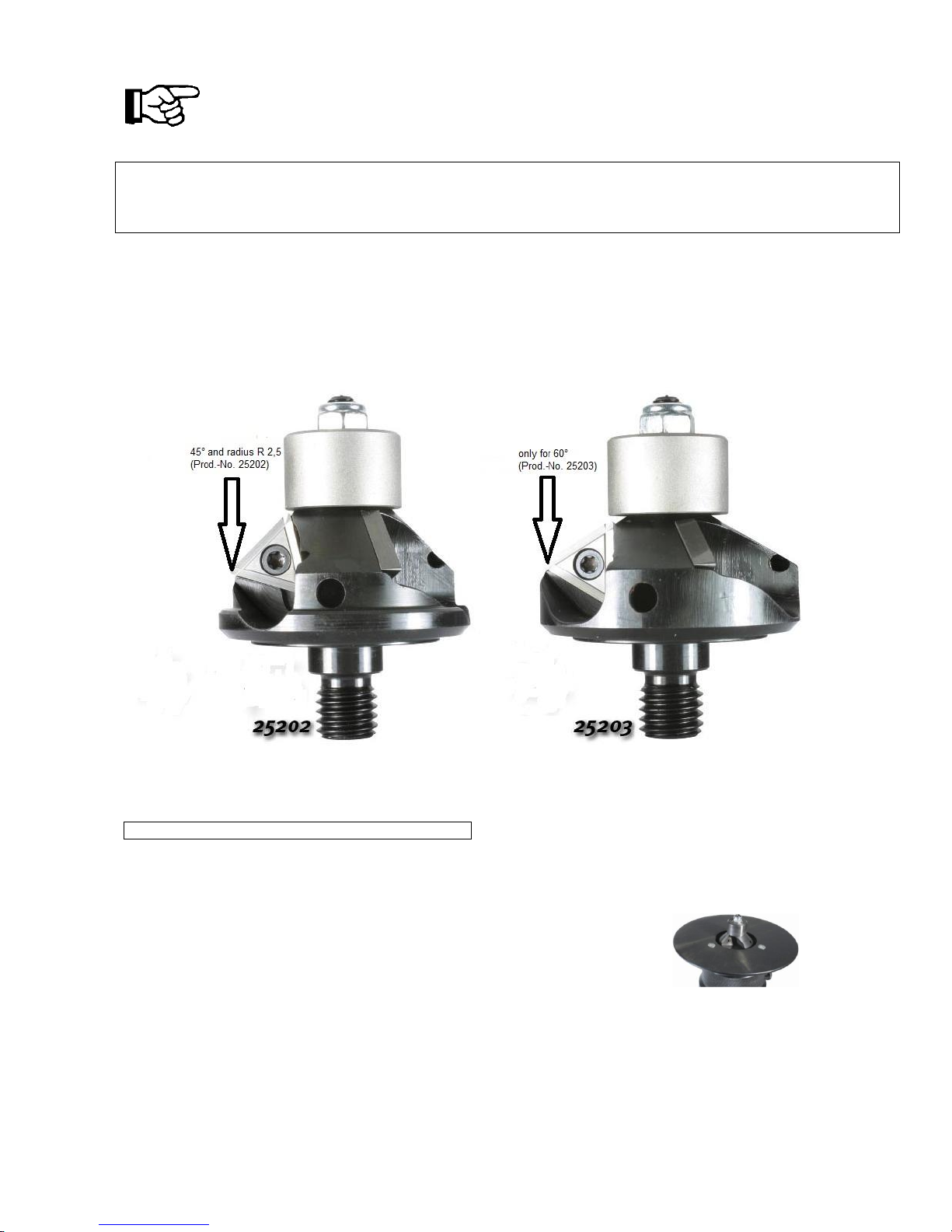

Cutter Head 45 ° and radius 2,5

Cutter Head only for 60°

For very quiet operation and high stock-removing capacity the device has been equipped with triple milling heads, with

3 cutting inserts each. These cutting inserts have 3 cutting edges. They are the actual tools for bevelling and

deburring. Depending on the material they can be used for machining steel, aluminium, aluminium alloys and plastics.

Suitable for machining chamfers of

Cutting inserts seize: 13,47 x 3mm / PM25 M coated .

Cutter Head with Radius 2,5 Cutting Insert

For bevelling and deburring, use the 2.5 mm radius cutter head, Prod.-No. 25202 together

with the cutting insert Prod.-No. 25205.

Suitable for steel of up to 600N/mm²

Note: When inserting the milling head with radius, the supporting plate must be rotated to achieve the correct position

(compare 4.1).

Prior to machining steel and aluminium or aluminium alloys, it is recommended to spray the cutting edges with cutting

oil-adhesive-foam spotty in order to achieve enhanced machine ability of the edges and higher durability of the cutting

inserts.

6

Working with the B5 Deburring Device

The motor has a speed governor which can be used to adjust the speed to the relevant material. Infinitely variable from

6,000 to 10,000 min-1.

The ON/OFF switch is located on the handle.

Do not start working on the job until the correct speed has been reached.

Work on material.

When bevelling or deburring, the device must always be guided from left to right (up-cut

milling).

Operation with the device in all positions must be carried out with both hands.

Switching Off

1. Withdraw device from material.

2. Operate ON/OFF switch, the motor is turned off.

Attention:

Perform regular wear checks on cutting inserts. Sharp cutting inserts ensure efficient cutting performance and prevent

device from damage. Ensure to rotate or replace blunt or cracked cutting inserts when due.

Maintenance Intervals

Transmission and gearhead: Lubrication carried out by a specialist at every 100 operating hours or replace

lubricating grease.

Recommended grease: Grease off the type MSN 2 (Rhenus Norlith)

The first gear chamber needs to be filled up with 20 g

and the gear chamber on the motor side with 17 g.

Mounting thread on Clean and lubricate as necessary.

transmission housing:

Motor air vents: Clean as necessary.

Cutting inserts: Rotate or replace as necessary.

Ball bearing race: Replace as necessary.

Tool change: Push the shaft lock on the motor to the side and rotate milling head counter-

clockwise. Completely remove cutting insert holder.

7

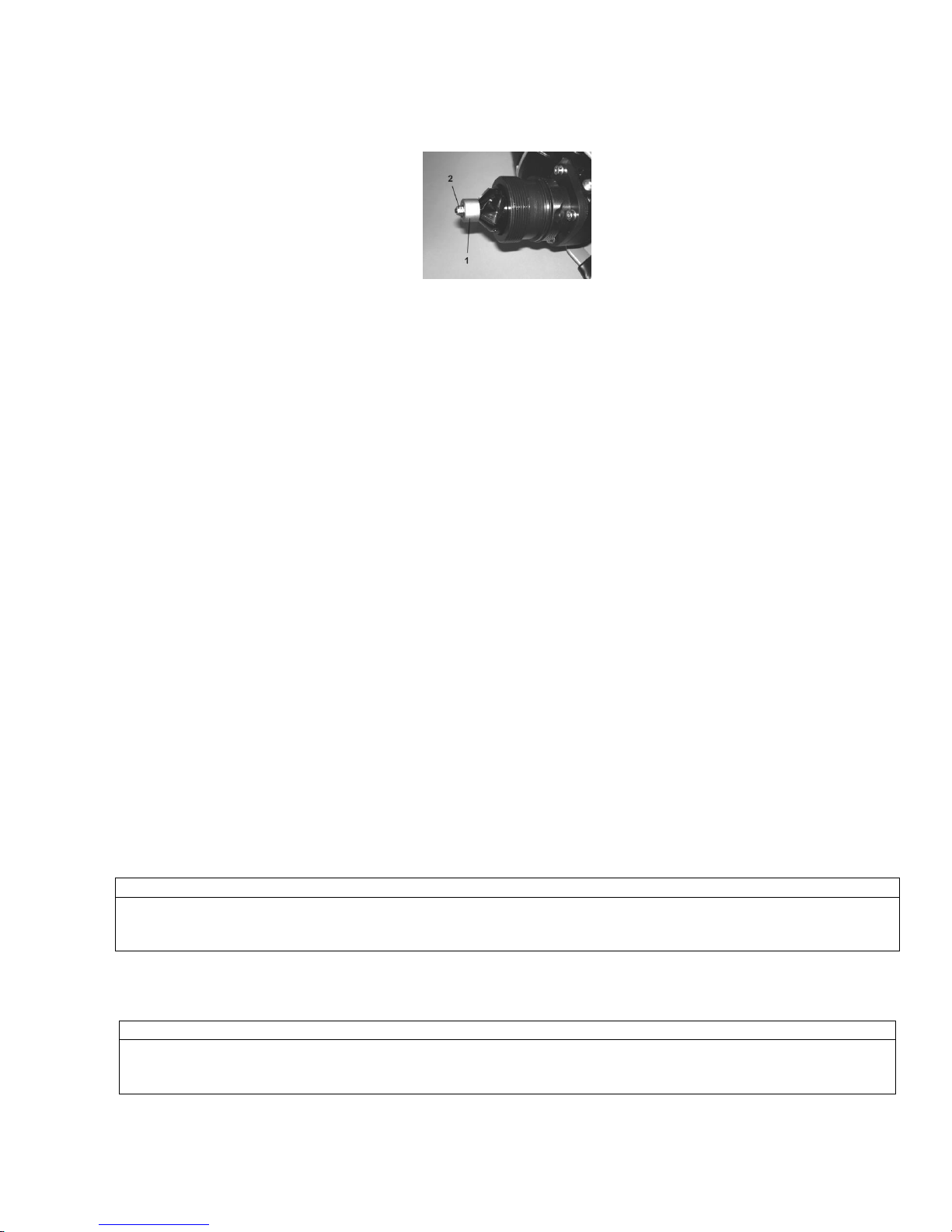

Changing the Cutting Head

1) Loosen knurled screw and remove support plate with adjusting collar.

2) Press release button and engage drive shaft.

3) Loosen cutting head counter clockwise with hook wrench (supplied).

1 = Support plate with

adjusting collar.

1 = Release button.

2 = Drive shaft.

For refitting, proceed in reversed order. It will suffice to tighten the cutting head to hand tight with the hook wrench.

Changing the cutting inserts

1) Loosen cutting insert fastening bolt with torx wrench (T 10, supplied) and remove cutting inserts. Repeat this

procedure in the same way for each of the three cutting inserts.

2) Rotate or replace cutting inserts.

3) Refit cutting inserts with fastening bolt (tighten to hand tight).

There is no need to remove the cutting head when changing the cutting inserts. It will suffice to turn home the support

plate with the adjusting collar.

1 = Cutting insert.

8

Changing the Ball Bearing Race

Any worn out ball bearing must be duly replaced in order to prevent the chamfer surfaces from suffering irregular

machining.

1 = Ball bearing.

2 = Hex nut.

a) Loosen lower hex nut (2).

b) Pull away and replace ball bearing race.

c) Fit new ball bearing race with hex nut (2).

Replacing Carbon Brushes

With the carbon brushes worn out the motor will stall or the collector will be damaged. Have carbon brushes checked

and replaced by a specialist as necessary.

Only use original carbon brushes and follow instructions on rating plate.

Spare Parts

In order to ensure correct and rapid delivery of genuine consumables:

1) State part number according to attached exploded drawing.

2) Enter more order data such as:

Voltage data, quantity, machine type and purchase date.

3) State complete shipping address:

Correct address, desired type of dispatch.

Replacement inserts

Description Prod.-No.

Radius insert 2.5 mm 25205

Indexable insert BK84 for steel/stainless steel 22209

Torx screws, individually, for spare indexable inserts 25210

Replacement cutting heads

Description Prod.-No.

45° spare insert holder/radius R=2.5 (without indexable inserts) 25202

60° spare insert holder (without indexable inserts) 25203

Adjustable guide stop for outer edges 25207

Chip Removal and Cleaning

9

Regularly remove metal chips from device.

Always keep your working space clean.

For collecting chips, use our magnetic chip collector, Prod.-No. 18654:

Remember to turn off the device while collecting the chips. Never remove chips with your bare hands. Risk of injury!

Scope of Supply

According to the current offer.

Limitation of Liability

All technical information, data and instructions for use and maintenance of the device contained in this user manual

were last updated prior to delivery and have been of our previous experience and findings to the best of our

knowledge. This manual is subject to technical modifications on the basis of further development.

We do not assume liability for damage and malfunctions caused by operating errors, failure to follow the instructions of

these manual or inappropriate repairs. Any arbitrary modifications or alterations to the device are prohibited for safety

reasons and exclude a nonwarranty clause for resulting damage. Claims for damages, derived from whichever legal

ground, are excluded.

Warranty

The manufacturer grants a warranty of 12 months. For our Bevelling and Deburring Machines we grant guarantee

according to the legal and regional regulations (proven by invoice).This warranty is only valid with the carrying out of

the instructions of the Operation Manual and correct purpose of use.

The manufacturer is not legally liable for damages, caused by abuse, or misuse of instructions of this Operation

Manual.

Rights to claim under guarantee are out of question, in case the Bevel Milling Machine is, without written authorization

of the manufacturer, changed in construction or functional execution. If the electric tool is modified without our

authorization, this declaration will lose its validity and the guarantee expires.

10

EC Declaration of Conformity

N.KO,spol. s r.o.

Táborská 398//22

293 01 Mladá Boleslav

Czech republic

declare that the build of this

B5 type Deburring Device

complies with the provisions of the Safety of Machinery EC Directive as in 91/368/EEC.

The applied, harmonised standards are:

EN 292, Part 1, Safety of Machines

EN 60204, Part 1, Electrical equipment of machines

Technical documentation is available.

The user manual is supplied with the device.

11

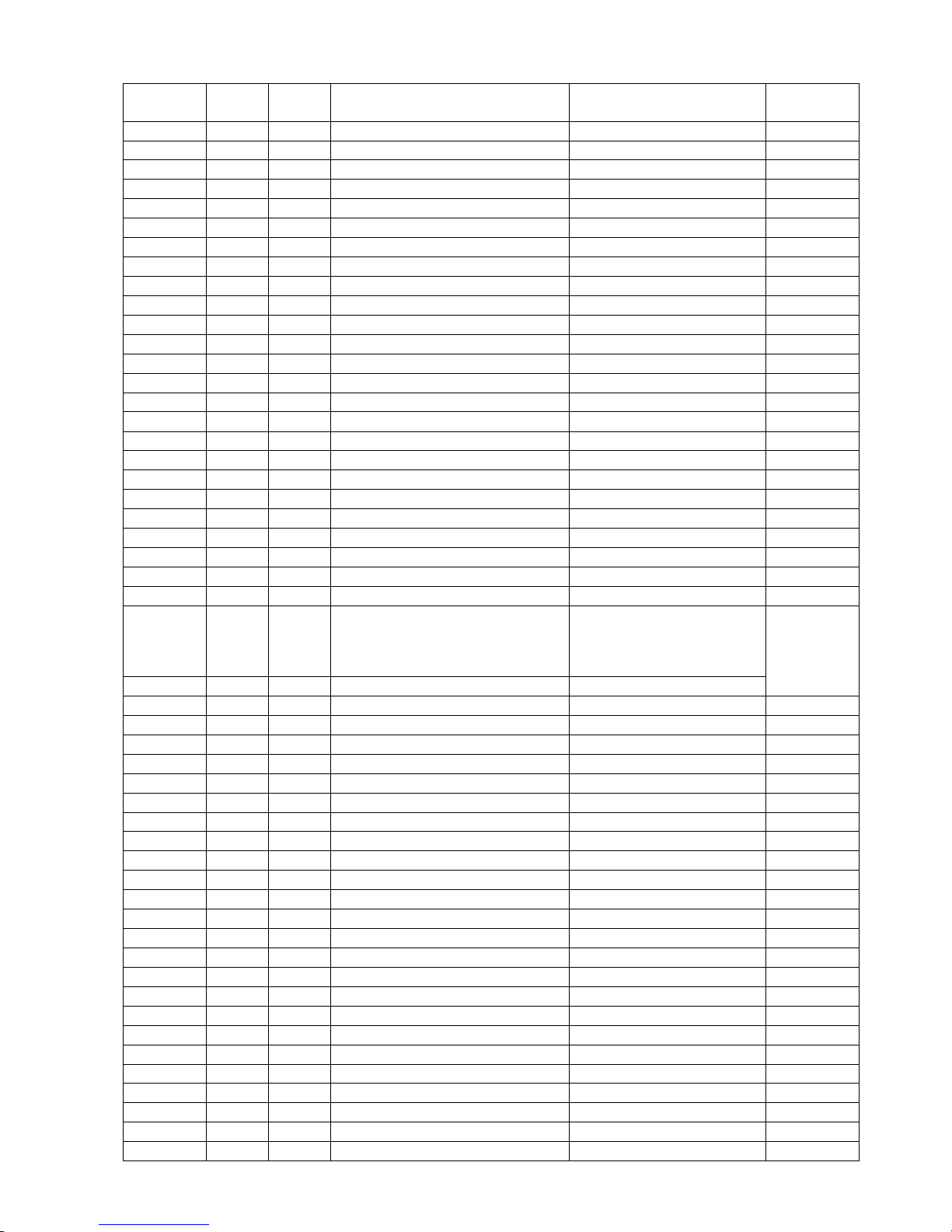

Spare Parts List and Spare Part Drawing for Deburring Device B5

12

NKO-N°

Pos.

Menge

25195-001

1

1

Rotor s ventilátorem

armature with ventilation

230V 1,5kW

25195-017

17

1

Kompletní stator

stator complete

230V 1,5kW

25195-034

34

1

Skříň statoru

stator housing

reinorange

25195-035

35

2

Držák uhlíků

brush holder incl. flange

25195-037

37

1

Kuličkové ložisko

ball bearing 627-2RS-J/Y

7x22x7

25195-038

38

1

Kuličkové ložisko

ball bearing 627-2RS-J/Y

25195-039

39

2

Uhlík

carbon

230V

25195-040

40

2

Šroub statoru

stator-screw-fixation

25193-09

41

1

Vývodka

protection sleeve

25191-11

42

2

tapping screw

25191-12

43

1

Těsnění

insulation ring

25195-044

44

1

Vložka

supporting ring

25193-19

45

1

Kruhový magnet

ring magnet

25191-18

46

1

Talíř

disk

M3

25191-14

47

1

Šroub

countersink screw

M3x8

25195-049

49

1

Kryt ventilace

ventilation cover

25195-050

50

1

Záslepka

blinds

25195-052

52

1

Rukojeť levá

half shell handhold left

schwarz

25195-053

53

1

Rukojeť pravá

half shell handhold right

schwarz

25191-19

54

4

Šroub

tapping screw BZ

ø3.5x12

25191-47

55

2

Šroub

tapping screw B

ø3.5x25

25195-056

56

1

Vypínač

switch

2200.0601

25195-057

57

1

Klip kabelu

cable bridge

25195-058

58

1

feeding cable

VDE

25195-061

61

1

Regulace

electronic 230V

15 - 33k

189302115

62

1

Frézovací hlava 45° + R2,5 (pouze těleso

hlavy)

Cutter head 45° and R 2,5

(cutter head only; without cutting

inserts and startup ball bearings)

189302116

(62)

1

Frézovací hlava 60°

Cutter head 60°

25206

63

3

Břitové destičky

Cutting insert

25210

64

3

Šroub břitových destiček

Bolt

189302118

65

2

Ložisko vodící rolny

Deep groove ball bearing

686 ZZ

189302121

68

1

lock washer

16/1

189302119

66

1

Vodící rolna

Stop

189302120

67

1

Samojistící matice

Hex nut

M6

25195-100

100

1

lock washer

25195-102

102

1

Těsnění

sealing

25195-103

103

1

Pastorek

Pinion

25195-104

104

1

Matice

screw nut

M7

25195-105

105

1

Hlava

crosshead

25195-106

106

1

Kolík

blocking pin

25195-107

107

1

O-kroužek

o-ring

4.5x1

25195-108

108

1

Pružina

Spring

25195-109

109

1

Tlačítko

button

25195-110

110

1

Špice

needle bush

25195-111

111

4

Šroub

screw

25195-117

117

1

Vřeteno

spindle

25195-118

118

4

Šroub

screw

M4 x 20

25195-119

119

1

Těsnění

sealing flange

25195-120

120

1

Podložka

washer

25195-121

121

1

O-kroužek

o-ring

50x2

25195-122

122

1

Jistící kroužek

Adjusting ring

25195-123

123

1

Kolo

spindel gear

13

25195-124

124

1

Držák

handhold

25195-125

125

1

Talíř vedení

Disc

25195-126

126

1

Doraz

stop

25195-127

127

2

Kámen

tensioning block

25195-128

128

1

Kámen max. nastavení

limit stop block

25195-129

129

2

Ložisko

deep groove ball bearing

6004 1RZ

25195-130

130

1

Podložka

lock washer

DIN 471 Ø20

25195-131

131

1

Ségrovka

snap ring

DIN 472 Ø42

25195-132

132

1

O-kroužek

o-ring

Ø52 x 3 NBR70

25195-133

133

3

Šroub

countersink screw

M4 x 8

25195-134

134

2

Křídlová matice

wing screw

M5 x 10

25195-135

135

2

Kolík

dowel pin

Ø4 x 10

25195-136

136

1

Šroub aretační

knurled screw

25195-137

137

1

Šroub

cylinder head screw

M5 x10

25195-200

200

16

Tuk převodovky

grease

N.KO, spol. s r.o.

Táborská 398//22

293 01 Mladá Boleslav

Czech republic

This manual suits for next models

1

Other N.KO Tools manuals