CONTENTS

2

www.krohne.com 09/2018 - 4006564001 - AD IECEX OPTIFLEX x200 R01 en

OPTIFLEX X200

1 General safety information 4

1.1 Scope of the document..................................................................................................... 4

1.2 Device description ............................................................................................................ 4

1.3 Standards and approvals.................................................................................................. 4

1.4 Equipment protection levels (EPL)................................................................................... 5

1.4.1 Ex ia-approved devices ........................................................................................................... 5

1.4.2 Ex ia/db- and Ex ia/tb-approved devices ................................................................................ 6

1.4.3 Ex ic devices ............................................................................................................................ 8

1.4.4 Ex ic nA devices....................................................................................................................... 9

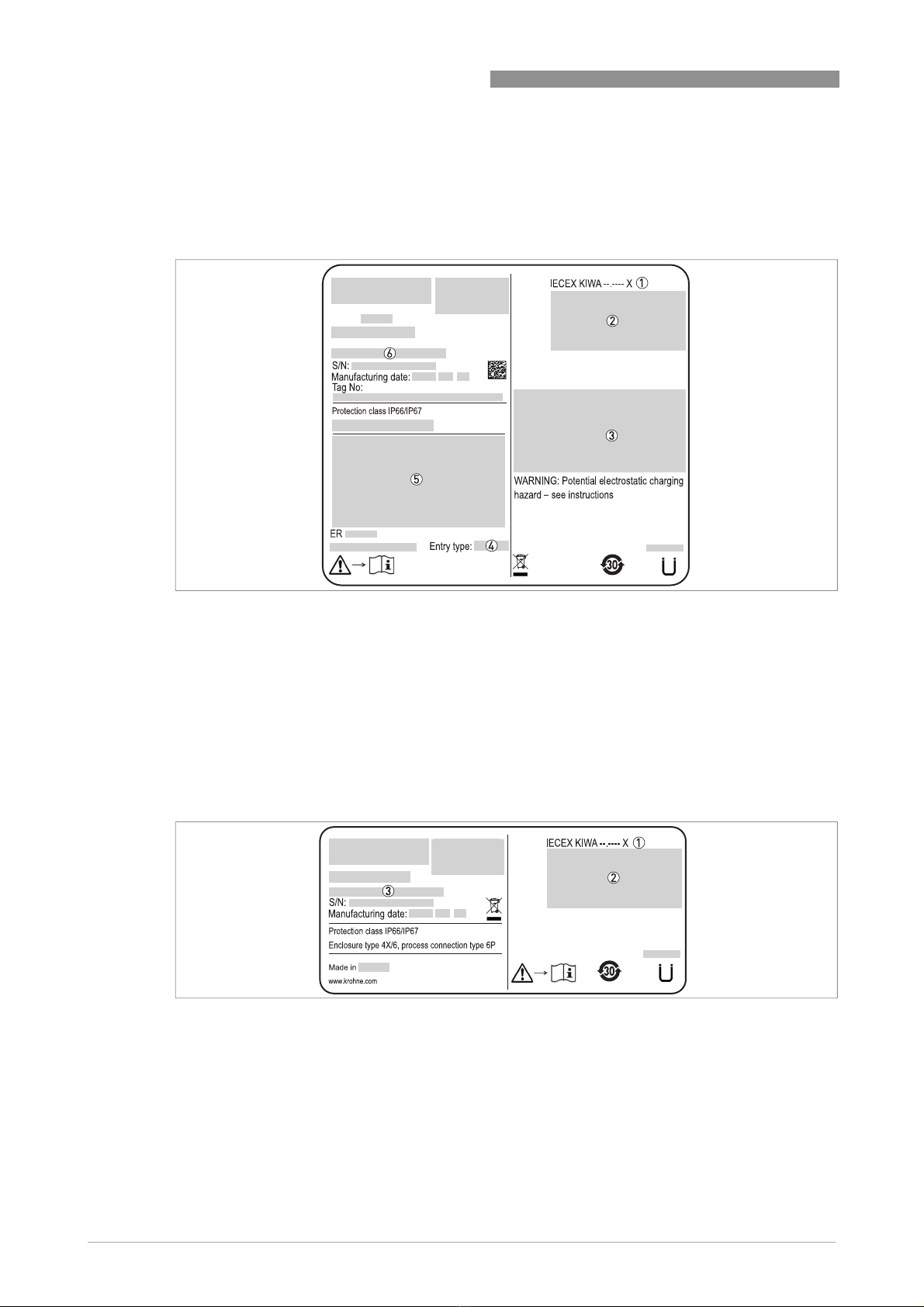

1.5 IECEx nameplates .......................................................................................................... 10

2 Installation 11

2.1 Special conditions........................................................................................................... 11

2.2 Precautions..................................................................................................................... 11

2.2.1 General notes........................................................................................................................ 11

2.2.2 Electrostatic discharge......................................................................................................... 11

2.3 Operating conditions: ambient and process connection temperatures........................ 12

2.3.1 General notes........................................................................................................................ 12

2.3.2 OPTIFLEX 3200 C (compact converter version).................................................................... 13

2.3.3 OPTIFLEX 3200 F (remote converter version) ...................................................................... 14

2.3.4 OPTIFLEX 6200 C (compact converter version).................................................................... 15

2.3.5 OPTIFLEX 6200 F (remote converter version) ...................................................................... 17

2.3.6 OPTIFLEX 7200 C (compact converter version).................................................................... 18

2.3.7 OPTIFLEX 7200 C (compact) converter: replacement for the OPTIFLEX 1300 C converter 21

2.3.8 OPTIFLEX 7200 F (remote converter version) ...................................................................... 23

2.3.9 OPTIFLEX 7200 S (compact converter with sensor extension version) ............................... 25

2.3.10 OPTIFLEX 7200 D (remote converter with sensor extension version) ............................... 27

2.3.11 OPTIFLEX 8200 C (compact converter version).................................................................. 29

2.3.12 OPTIFLEX 8200 F (remote converter version) .................................................................... 32

2.3.13 OPTIFLEX 8200 S (compact converter with sensor extension version) ............................. 36

3 Electrical connections 38

3.1 General notes ................................................................................................................. 38

3.2 Terminal compartment .................................................................................................. 38

3.2.1 How to open the terminal compartment .............................................................................. 38

3.2.2 How to close the terminal compartment ............................................................................. 39

3.3 Terminal tightening capacity.......................................................................................... 40

3.4 Output options: terminals .............................................................................................. 41

3.4.1 One current output: 4...20 mA passive - HART..................................................................... 41

3.4.2 Two current outputs: 4...20 mA passive - HART + 4...20 mA passive .................................. 42

3.4.3 One current output and one switch output: 4...20 mA passive - HART + switch output (relay)

... ..................................................................................................................................................... 42

3.4.4 Modbus RTU .......................................................................................................................... 43

3.4.5 FOUNDATION™ fieldbus or PROFIBUS PA........................................................................... 43

3.5 Equipotential bonding system........................................................................................ 44