8.2.1 Edition 08.10

DK S N P GR

➔ www.docuthek.com

D GB F NL I E

TR CZ PL RUS H

© 2008 – 2009 Elster GmbH

Please read and keep in a safe place

Please read through these instructions

carefully before installing or operating. Follow-

ing the installation, pass the instructions on to the

operator. These instructions can also be found at

www.docuthek.com.

Explanation of symbols

• , 1 , 2 , ... = Action

= Instruction

Liability

We will not be held liable for damages resulting

from non-observance of the instructions and non-

compliant use.

Safety instructions

Information that is relevant for safety is indicated in

the instructions as follows:

DANGER

Indicates potentially fatal situations.

WARNING

Indicates possible danger to life and limb.

CAUTION

Indicates possible material damage.

All interventions may only be carried out by qualified

gas technicians. Electrical interventions may only be

carried out by qualified electricians.

Conversion, spare parts

All technical changes are prohibited. Only use OEM

spare parts.

Transport

On receipt of the product, check that the delivery is

complete (see Part designations). Report any trans-

port damage immediately.

Storage

Store the product in a dry place. Ambient tempera-

ture: see Technical data.

Operating instructions

Translation from the German

GB

GB-1

Safety

Contents

UV sensor UVS 10

UV sensor UVS 10 ......................1

Contents ..............................1

Safety.................................1

Checking the usage . . . . . . . . . . . . . . . . . . . . . 2

Type code..............................2

Installation ............................2

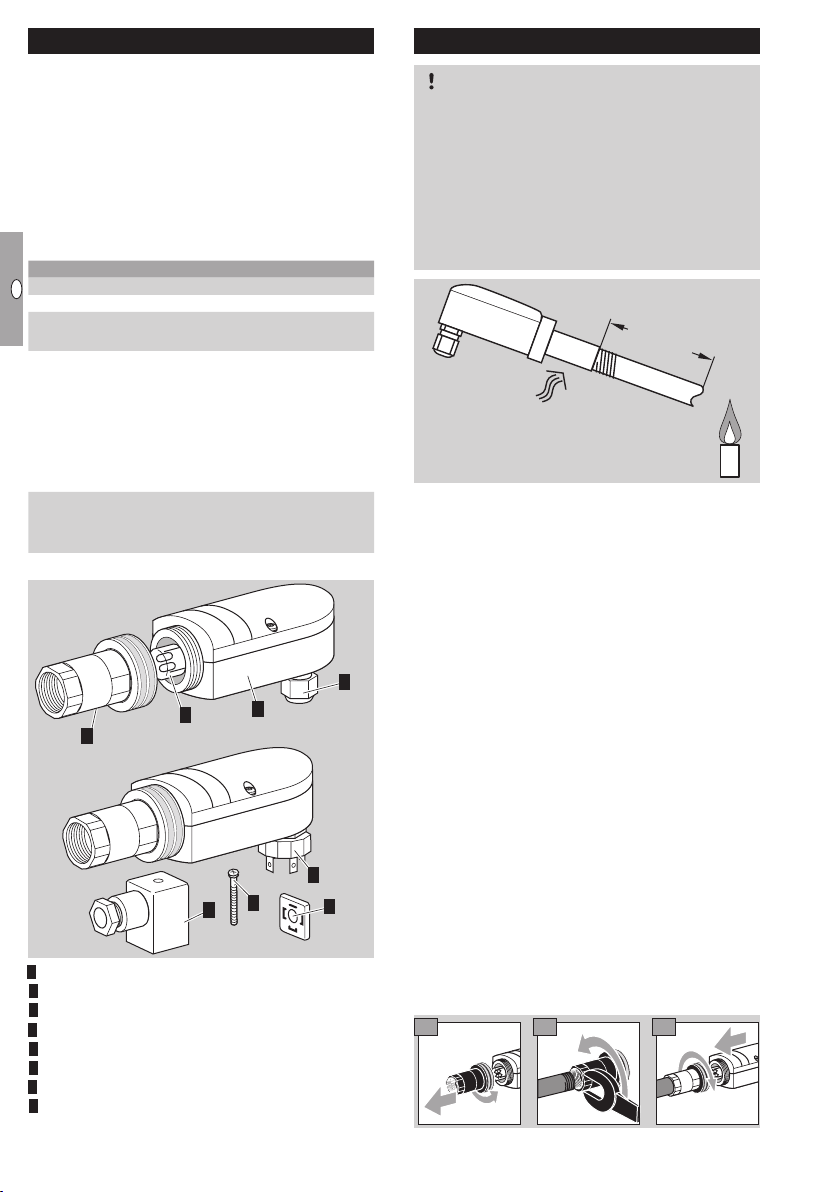

UVS 10 with internal thread adapter. . . . . . . . . . 2

UVS 10 with UVS 1 adapter. . . . . . . . . . . . . . . . 3

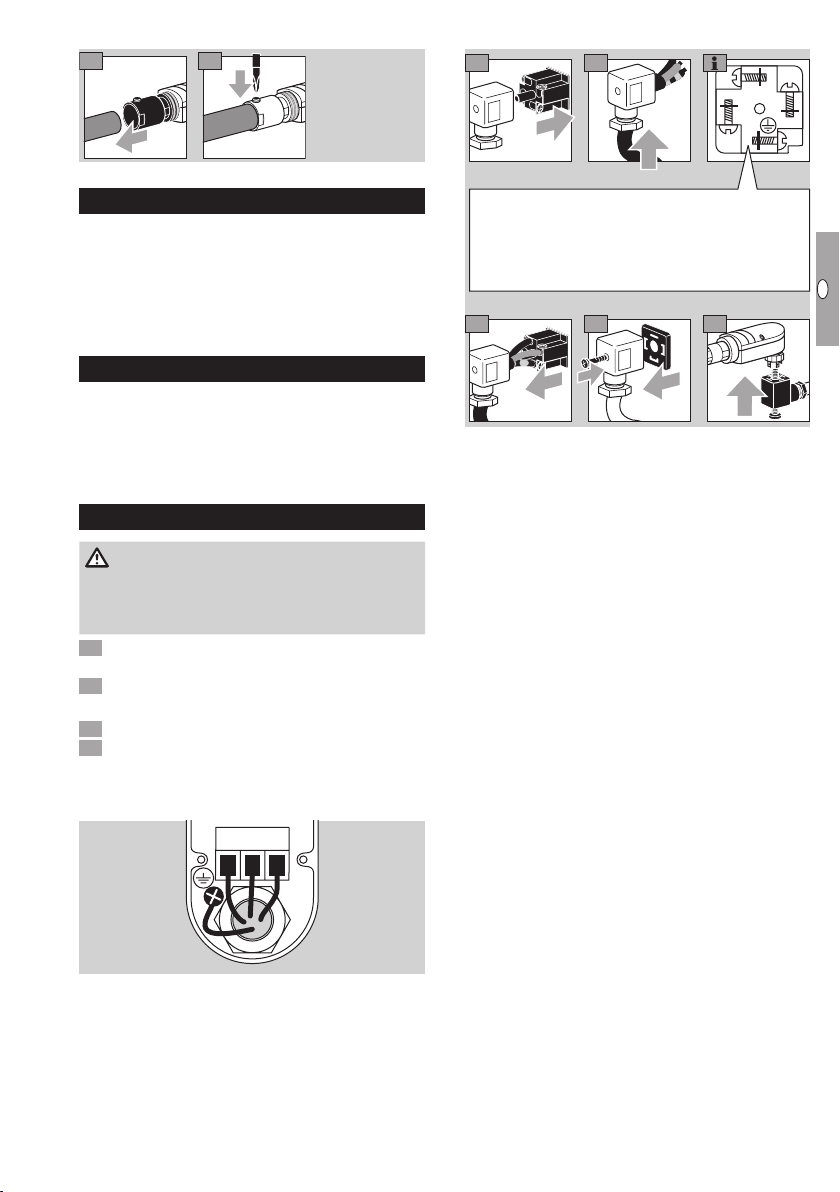

Cable selection.........................

Cable installation .......................

Wiring ................................

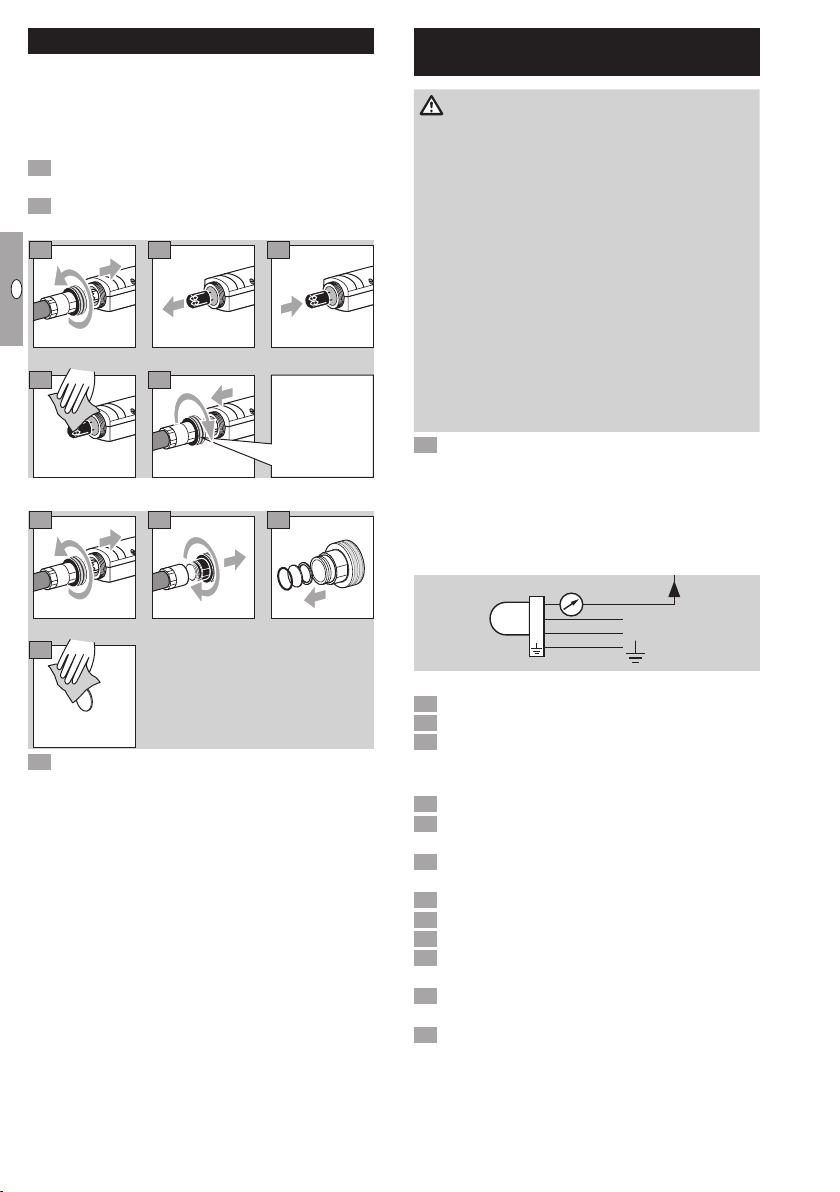

UVS 10..G1............................3

UVS 10..P2 ............................3

Maintenance...........................4

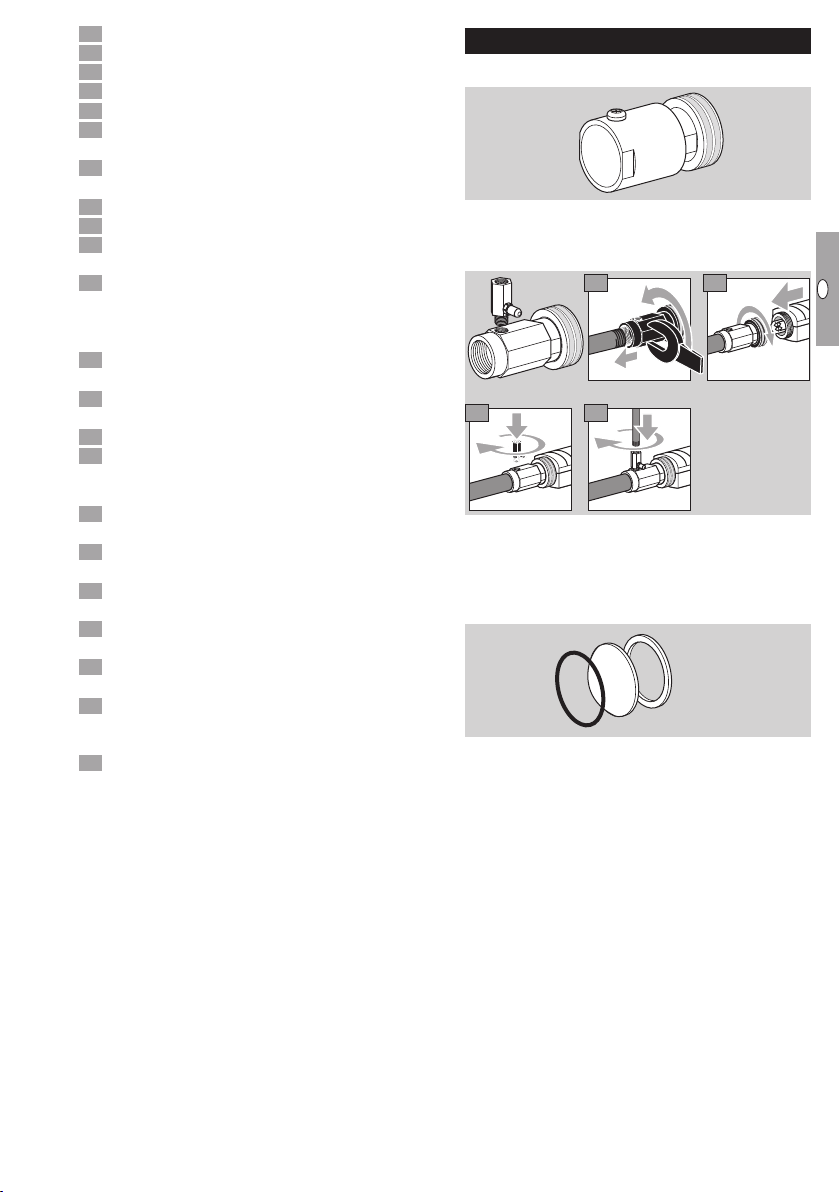

Replacing the UV tube . . . . . . . . . . . . . . . . . . . . 4

Cleaning or replacing the quartz glass disc . . . . 4

Assistance in the event of malfunction . . . . . 4

Accessories ...........................5

Adapter UVS 1 with quartz glass disc . . . . . . . . 5

Cooling air adapter with quartz glass disc . . . . . 5

Quartz glass lens with seals . . . . . . . . . . . . . . . . 5

Technical data..........................6

Contact ...............................6