Amamix - direct

3

1 Pre-conditions for Installation

1.1 General

- Safety

This operating manual contains basic instructions, which must be

observed during installation, operation and servicing. Therefore

it is imperative that this manual is read prior to assembly by the

installer and relevant skilled staff/and operators, and it must

always be kept within the locality of the machine/plant.

Do not only observe the general safety notes under this section,

but as well any other notes regarding safety included in the

manual.

- Marking of Instructions

All safety instructions included in this manual are preceded by the

general hazard symbol, i.e.

The non-observance of this symbol may pose a health hazard to

those attending the site.

Warnings against electrical danger are preceded by this symbol:

The non-observance of this symbol may pose a health hazard to

those attending the site.

All safety instructions in this operation manual, the

non-observance of which may endanger the mixer itself or its

safe operation are preceded by the word

Attention

- Personnel Qualification and Training

All personnel involved in the operation, maintenance, inspection

or installation of the mixer must be qualified for the work in

question. The personnel’s responsibilities, competence and

supervision must be clearly defined by the user. To the extent that

the personnel in question is not already in possession of the

required skills and know - how, appropriate training and

instructions must be provided for. If required, the

manufacturer/supplier will provide such training at the user’s

request. In addition, the user is responsible for ensuring that the

contents of the operation manual are fully understood by the

personnel involved in the work.

- Dangers Resulting from Non - compliance with the

Safety Instructions

Non-compliance with the safety instructions may endanger the

safety of people, property, the environment and the mixer itself.

Non-compliance with the safety instructions will also lead to the

forfeiture of any and all rights to claims for damages.

More specifically, non-compliance may, for example, result in:

- Failure of essential mixer and/or plant functions;

- Health hazard due to electrical shock, mechanical impact,

chemical contamination.

- Pollution of the environment by the leakage of

hazardous substances.

- Safety Awareness

It is imperative to comply with the safety instructions contained in

this operation manual, the relevant national accident prevention

regulations and any of the user’s own work, operation and safety

regulations.

- Safety Instructions for the User / Operator

Take the necessary precautions to preclude all electrical hazards

(for more information, consult the stipulations of the local power

supply companies).

Safety Instructions for Maintenance, Inspection and

Installation Work

The user is responsible for ensuring that all maintenance,

inspection and installation work is carried out by duly authorized,

adequately qualified, specialist personnel who are thoroughly

familiar with the contents of this operation manual.

As a general rule, work on the mixer must only be performed

during standstill. The shutdown procedure described in the

manual for taking the machine out of service must be strictly

adhered to.

Mixers used to handle hazardous substances have to be

decontaminated.

Immediately following completion of the work, all safety-relevant

and protective devices must be re-installed and/or re- activated.

Please follow all instructions set out in the chapter entitled

“Commissioning” before returning the machine to service

(included in the mixer operating instructions, 1592.87.1-14).

- Unauthorized Modification and Manufacture of Spare

Parts

Neither the unit itself nor any installation hardware or accessory

may be modified or altered in any way without the prior consent

of the manufacturer.The use of genuine spare parts and

accessories approved by the manufacturer helps ensure the

operational safety and reliability of the equipment. Please note

that the use of other than genuine parts and approved

accessories can invalidate the manufacturer’s liability for

consequential damage.

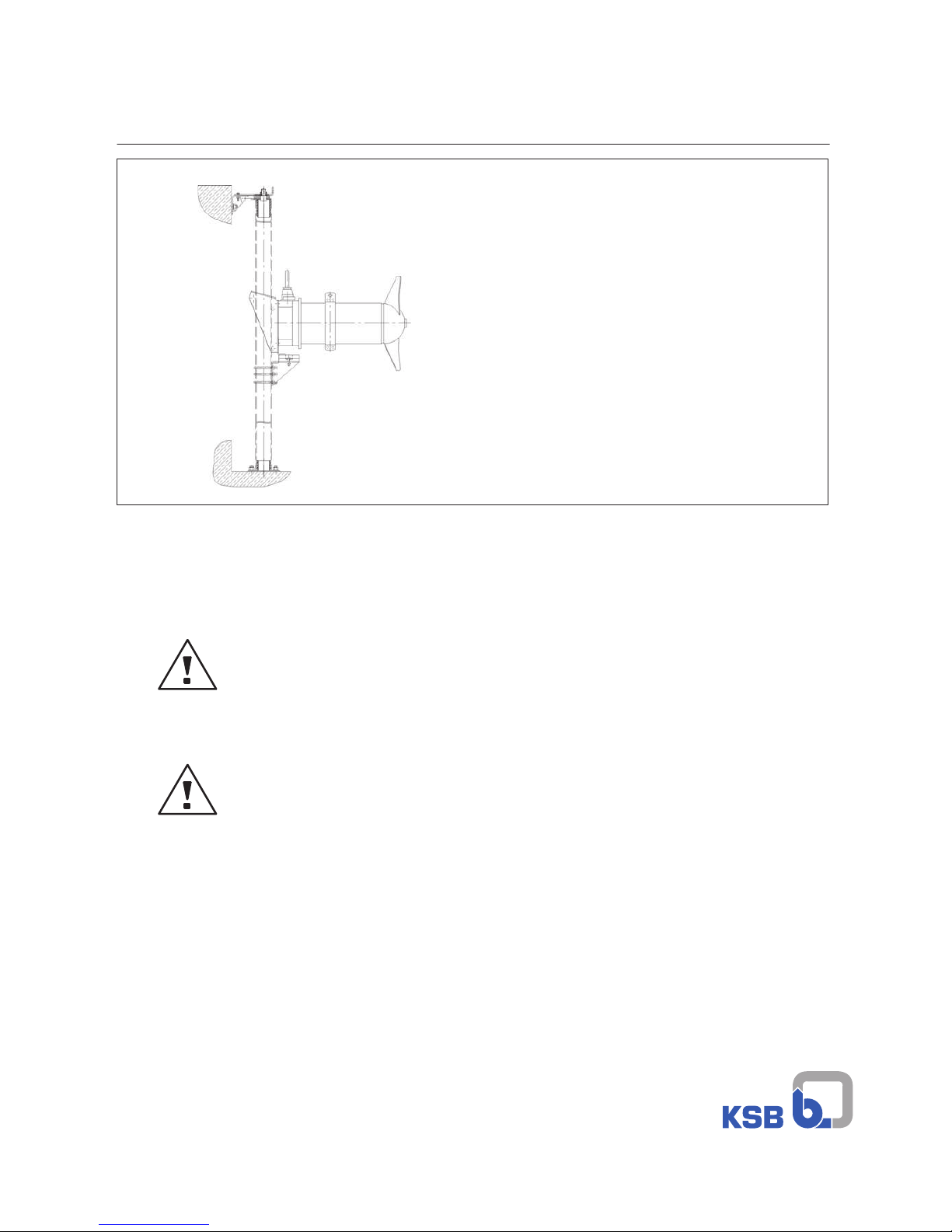

1.2 Checking the Site before Installation

Check that the building dimensions are in accordance with the

dimension sheet. To ensure that the carrying capacity of the

foundation is sufficient for installation of the unit, the strength of

the concrete must be at least 3,000 psi. Check that the concrete

foundation has set before proceeding with the installation of the

mixer.

Even if the reservoir floor is inclined, the surface must be leveled

if the installation parts are to be mounted to it securely.

1.3 Checking the Parts Before Installation

Before starting the installation, check that the installation parts

and accessories are complete and that they have not suffered any

transportation damage.