Ⅵ Ⅶ

4.4.1 Manual Transport ............................................................................19

4.4.2 Hoisting Transport ...........................................................................19

4.5 Dimensions of mounting-bracket ..............................................................20

4.6 PV Bracket-Mounted Installation ...............................................................21

4.6.1 Preparation before Mounting .............................................................21

4.6.2 Mounting Steps ................................................................................21

4.7 Wall-Mounted Installation ........................................................................23

4.7.1 Preparation before Mounting .............................................................23

4.7.2 Mounting Steps ................................................................................23

5 Electrical Connection 26........................................................................26

5.1 Safety Instructions ..................................................................................26

5.2 Terminal Description ...............................................................................26

5.3 Electrical Connection Overview ................................................................28

5.4 Additional Grounding Connection .............................................................30

5.4.1 Additional Grounding Requirements ..................................................30

5.4.2 Connection Procedure ......................................................................30

5.5 Opening the Wiring Compartment .............................................................31

5.6 AC Cable Connection ..............................................................................32

5.6.1 AC Side Requirements .....................................................................32

5.6.2 Requirements for OT/DT Terminal .....................................................34

5.6.3 Aluminium Cable Requirements .........................................................34

5.6.4 Connection Procedure ......................................................................35

5.7 DC Cable Connection ..............................................................................38

5.7.1 PV Input Configuration .....................................................................39

5.7.2 Connection Procedure ......................................................................40

5.7.3 Installing the PV Connectors .............................................................41

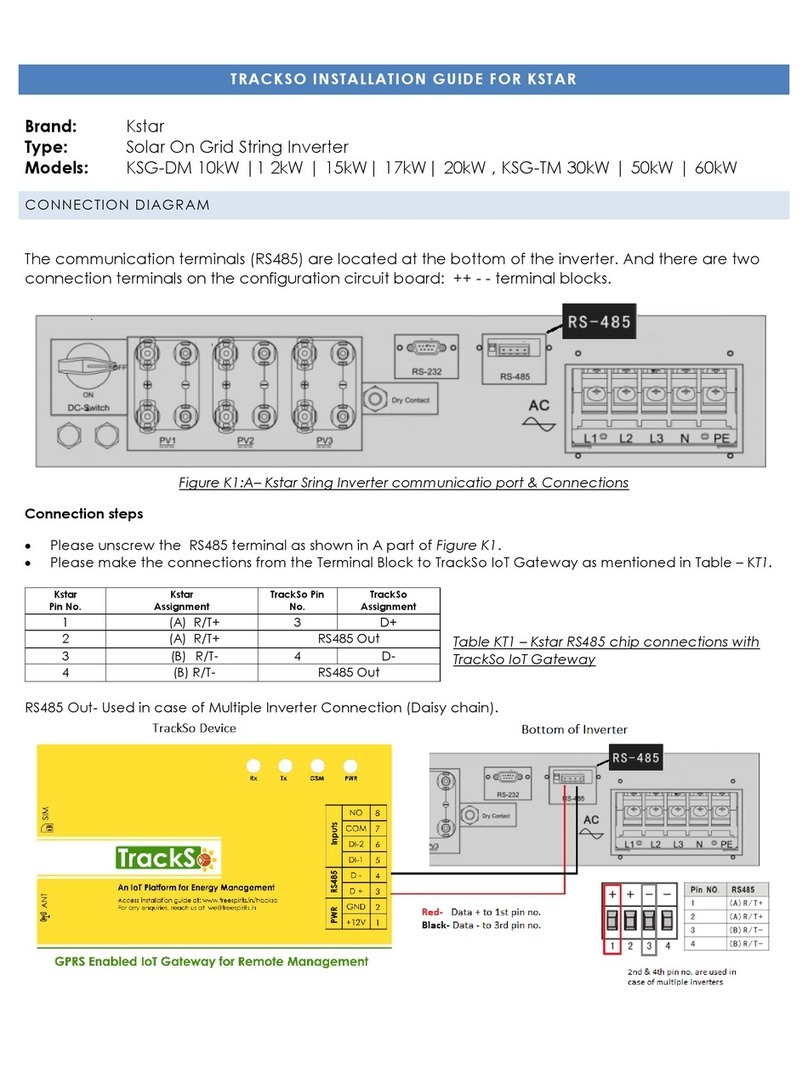

5.8 RS485 Communication ............................................................................42

5.8.1 Interface Description. .......................................................................42

5.8.2 RS485 Communication System .........................................................42

5.8.3 Connection Procedure(Terminal Block) .............................................43

5.9 PLC Communication Connection ..............................................................45

5.10 ...................................45Wiring of Tracking System Power Cable(Optional)

5.11 Closing the Wiring Compartment ............................................................46

6. ...................................................................................47Commissioning

6.1 Inspection before Commissioning...........................................................47

2 Commissioning Procedure.....................................................................47 6.

7. Bluetooth APP Settings....................................................................48

7.1 Overview...............................................................................................48

7.2 APP download........................................................................................48

7.3 Bluetooth connection..............................................................................48

7.4 Basic information interface......................................................................50

7.5 Query interface.......................................................................................51

7.6 Setting interface......................................................................................51

7.6.1 Set page information.......................................................................53

7.6.2 Related parameters setting interface................................................54

7.6.3 Set parameter information...............................................................55

7.7 Statistics interface.................................................................................58

8 System Decommissioning. .........................................................................59

8.1 Disconnecting the Inverter ........................................................................59

8.2 Dismantling the Inverter ...........................................................................60

8.3 Disposal of the Inverter .............................................................................60

9 Troubleshooting and Maintenance. ......................................................61

9.1 ......................................................................................61Error and alarm

9.1.1 Inverter system error type analysis and solution.................................62

9.2 .......................................................................................65Error and alarm

9.2.1 Routine Maintenance y......................................................................66

9.2.2 Maintenance Instruction ...................................................................66

10 Appendix. ...............................................................................................69

10.1 Technical Data .......................................................................................69

10.2 Quality Assurance ..................................................................................71

10.3 Contact Information ................................................................................71