ASSEMBLY INSTRUCTIONS4

TRACTOR PREPARATION

Park the tractor on a firm level surface. Stop the engine.

BEFORE ASSEMBLY

ABefore assembling the hardware (bolts, adapters,

hoses, etc.), ensure all contaminants (grease, grit,

dust, etc.) are removed from the threads and all mating

surfaces (Tractor, Main Frames, etc.). If oil or

contamination has adhered, clean off thoroughly

before assembling (by using contact cleaner,

scrapers, etc.). If oil or contamination remains on the

threads, it may lead to damaged threads and the

loosening of hardware and/or parts.

AFor the tightening torque, see the tables at the end of

this manual. If the torque values are specified in the

text, follow that specification.

ADo not tighten any bolts firmly until most components

are attached to the tractor.

ABefore tightening all mounting hardware, start the

engine and apply down pressure with the bucket until

the loader takes the tractor weight off the front wheels

without lifting the front wheels off of the ground. Make

sure that the mounting pins can be rotated easily (Pin

on mount), or the Swift-Tach hooks can be unlocked

easily (Swift-Tach mount). Torque all bolts and nuts in

this position.

ADuring assembly of all hydraulic parts make sure parts

remain clean of contamination. If contamination

occurs, it could affect the performance of the hydraulic

system.

AWhen using the tapered adapters, wrap the seal tape

around the thread part 2 or 3 times. At this time,

ensure all contaminants are removed from the

threads.

ATo avoid damage to hoses, adjust all connections to

route hoses away from sharp edges and do not twist

hoses.

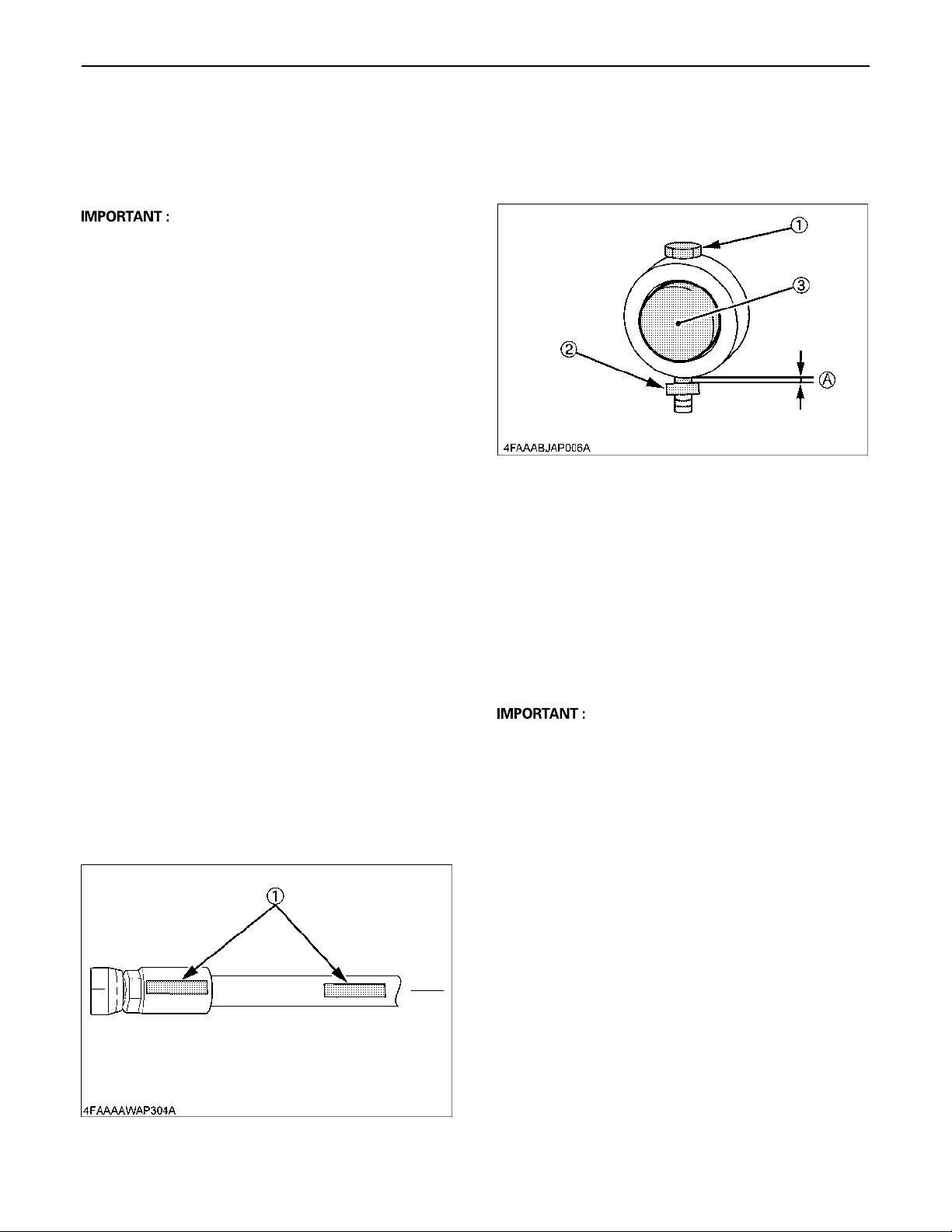

AThe part number of the hose is marked on the hose

fitting, or located on the hose.

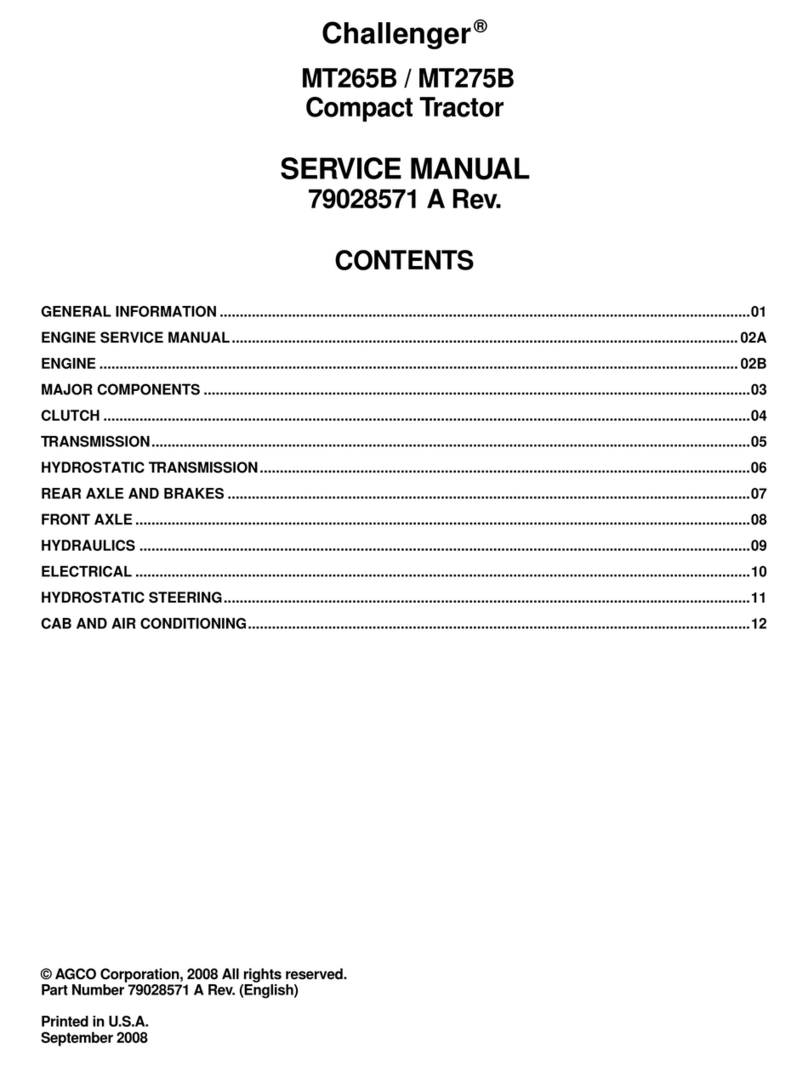

AWhen fixing the pin with the bolt and nut, do not tighten

the nut completely as shown. The clearance between

the boss and the nut should be 2 to 3 mm (0.08 to 0.12

in.).

AWhen applying label:

(1) Clean off all contaminants (dust, oil, grease, etc.)

from surface before applying label.

(2) Do not use the cotton work gloves or touch the

label adhesive surface with your hand.

AAssemble on a hard surface, preferably concrete.

ASSEMBLING LOADER KIT

BMain Frames

ABefore attaching the main frames, ensure all

contaminants (grease, grit, dust, etc.) are removed

from the threads and all mating surfaces. If oil or

contamination has adhered, clean off thoroughly

before assembling (by using contact cleaner,

scrapers, etc.). If oil or contamination remains on the

threads, it may lead to damaged threads and the

loosening of hardware and/or parts.

(1) Part number

(Marked on either position)

(1) Bolt

(2) Nut

(3) Pin

(A) 2 to 3 mm (0.08 to 0.12 in.)