41

. The porking broke is designed to hold troctor in

ploce ot rest, with engine off. Porking broke

will not restroin trocior with engine running ond

' tronsmission

engoged.

STABITITY

/ TIPOVER

/ TRACTION

42. Know the lerroin on which you ore operoiing

your equipmbnt. There ore oreos on which your

equipmenl con not be sofely operoted.

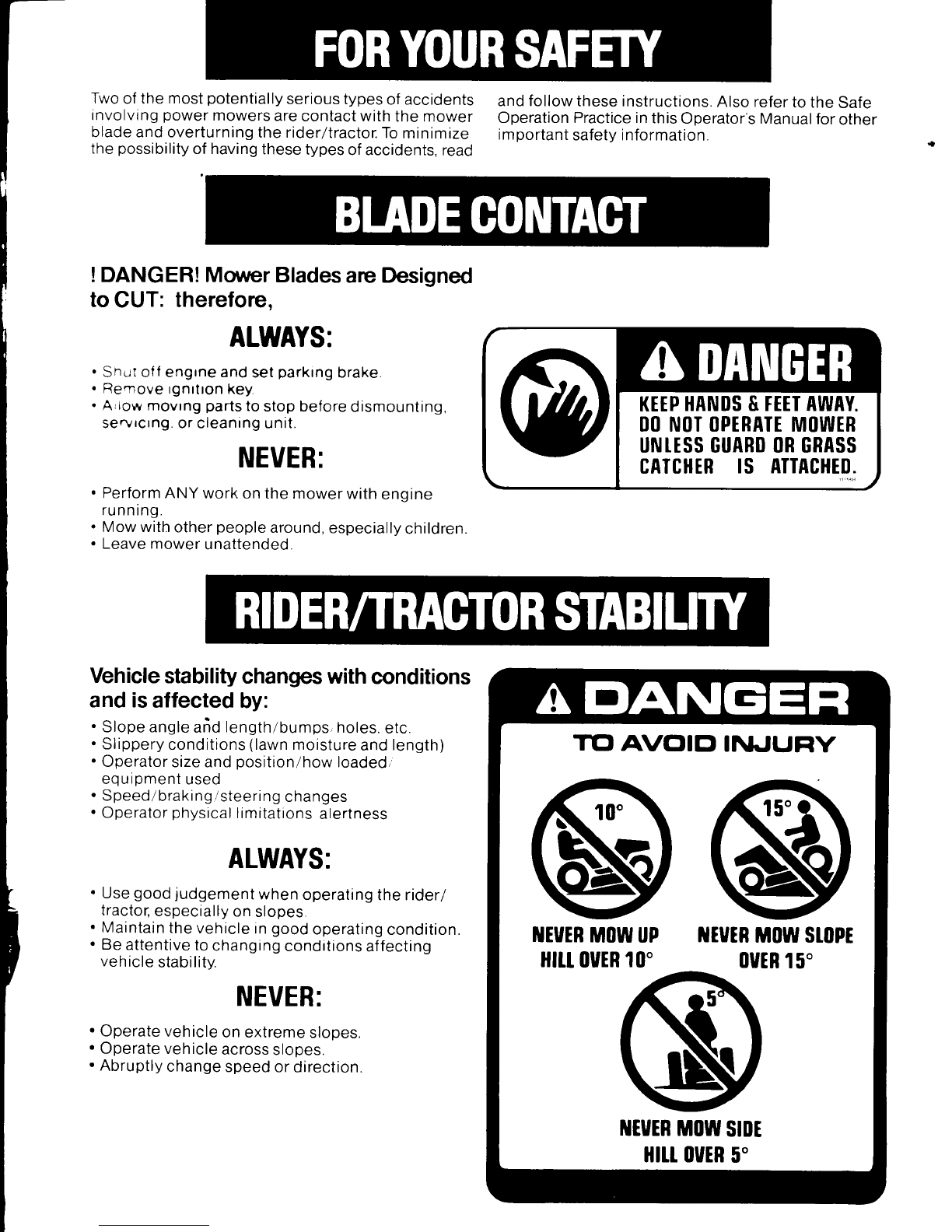

43. Avoid operoiing equipment on hillsides, slopes

or rough terroin. DO NOT operote mochine on

hillsides

or slopes exceeding 15" (27% grode).

lf sofefy is in doubt - STAY OFF THE SLOPE.

44. Reduce speed ond exercise exlreme coution on

slopesobove l0' (187o

grode) to prevent fipping

or loss of control. Never mow uphill on these

slopes- mow downhill only. lf o sieep hill must

be oscended,bock up fhe hill, ond drive forword

down fhe hill, keeping troctor in geor. lf neces.

sory to furn on hill, olwoys rurn downhill.

45. Mow up ond down the foce of slopes greoler

thon 5" (9"/" grode), never ocross the foce. Be

especiolly coutious when chonging directions on

oll slopes.

46. Operofe your mochine smoothly ond ot o ground

speed slow enough fo insure complete control

ot oll times. ,Avoid errotic operolion ond exces-

sive speed.

47. Shorp turns on ony terroin moy couse loss of

control. Reduce speed ond use coulion when

moking shorp turns.

48. Do not siop or storl suddenly when going uphill

or downhill. Avoid uphill storts. lf mochine is

stopped going up o slope, turn lhe oitochmenl

off ond bock slowly down the slope keeping the

mochine in geor. Do not stop or chonge geors

(speed)

on slopes.

49. Know the terroin on which you ore working. Find

hidden obstoclesby wolking through ond inspect-

ing the oreo prior lo operoting your equipment

in thot oreo. Ploinly mork obstocles, such os

rocks, ruls or holes ond stoy well cleor of ihese

obstocleswhen operoting.

50. While operoting, stoy olert for holes, rocks or

roots,which moy couse domoge to equipmenl or

upset. Keep ot leosl 3 ft. owoy from drop-offs,

ditches, creeks, culverts, woshouts ond public

highwoys.

51. Exercisecore when mowing qround o fixed ob-

iect

fo prevent the equipment or oitochment from

striking rhe obiect. When mowing never deliber-

otely run over ony foreign obiect.

52. Areos wet with dew, roin or snow will be more

slippery thon when dry, Areos covered with loose

grovel ore more slippery thon firm dry ground.

Greoier stopping distoncesore required in these

slippery oreos.

53. Leorn lo expecl chonges in operoiing condilions.

Adding or removing oltochments or weight to

your equipmentwill moke your mochineperform

differently. Roin, snow, loose grovel, wet gross,

etc.,chonge the troclive conditions of the terroin

requiring chonges in your operoting technique,

which moy include o decision nol fo operote on

thol terroin.

54. Use cqre when pulling loods or using heovy

equipmenf

.

A. Use only opproved drowbor hitch points.

B. Limit loods fo those you con sofely control.

C. Do not turn shorply. Use core when bocking.

D. Use counterweight(s) or wheel weights when

suggested in operolor's monuol.

ATTACHMENT USE

55. When using ottochmenis never direct dischorge

of moleriol foword bystonders nor ollow onyone

neor vehicle while in operofion.

56, When using mochine wilh mower:

A. Mow only in doylight or in good ortificiol

lishr.

B. Never moke o cufiing height odiusfment while

engine is running if operoior must dismount

fo do so.

C. Shut engine off when unclogging chute.

D. Check blode mounting bolts for proper right-

nessol frequent inlervols.

57. Keep honds ond feet owoy from rototing blode(s)

underneoth mower deck. Never ploce fool on

ground when mower is engoged or when mower

is in motion.

58. DO NOT operole mower ottochmeni without the

chute deflector or complete bogger in ploce.

59. Exercise core while moneuvering with gross

colcher. Front to reor stobility moy cnonge.

60. When using mochine with snowthrower ond oug-

er becomes plugged or iommed:

A. Declutch snowthrower ond stop lroclor en-

gine immediotely.

B. Disconnect spork plug wire(s).

C. Cleor snow from dischorgechuteif plugged.

D. lf ouger is iommed, remove foreign obiect

ond repoir ony domoge to snowthrower be-

fore coniinuing.

E. Reconnecl spork plug wire(s) ond resume

operolion.

61. Never permif onyone to stond neor snowthrower

ouger or dischorge opening. Obiects moy be

present

in snow, which when lhrown, could couse

iniury.

62. When using snow/dozer blodes:

A. Avoid hitting solid obiects. This con dom-

oge blode ond iniure operotor.

B. Alwoys trovel ot o sofe, slow speed.

63. Keep oll persons o sofe distonce owoy when

operofing tillers.Alwoys disengoge the PTO,low-

er the oltochmenl ond remove the ignition key

before moking ony odiuslments.

64. lf tiller storls io push troctor, disengoge PTO

clutchimmediotely.

65. Use choins, counterweight(s) or wheel weighls

when suggesled

in ihe operotor's

monuol.

MAINTENANCE

66. Keep oll nuts, bolls, fosteners ond screws lighl

to be sure equipment is in sofe working condi-

tion ond check

them frequently.

Repoiror reploce

worn, domoged, distorted or broken Ports os

needed.