23

4

7

5

6

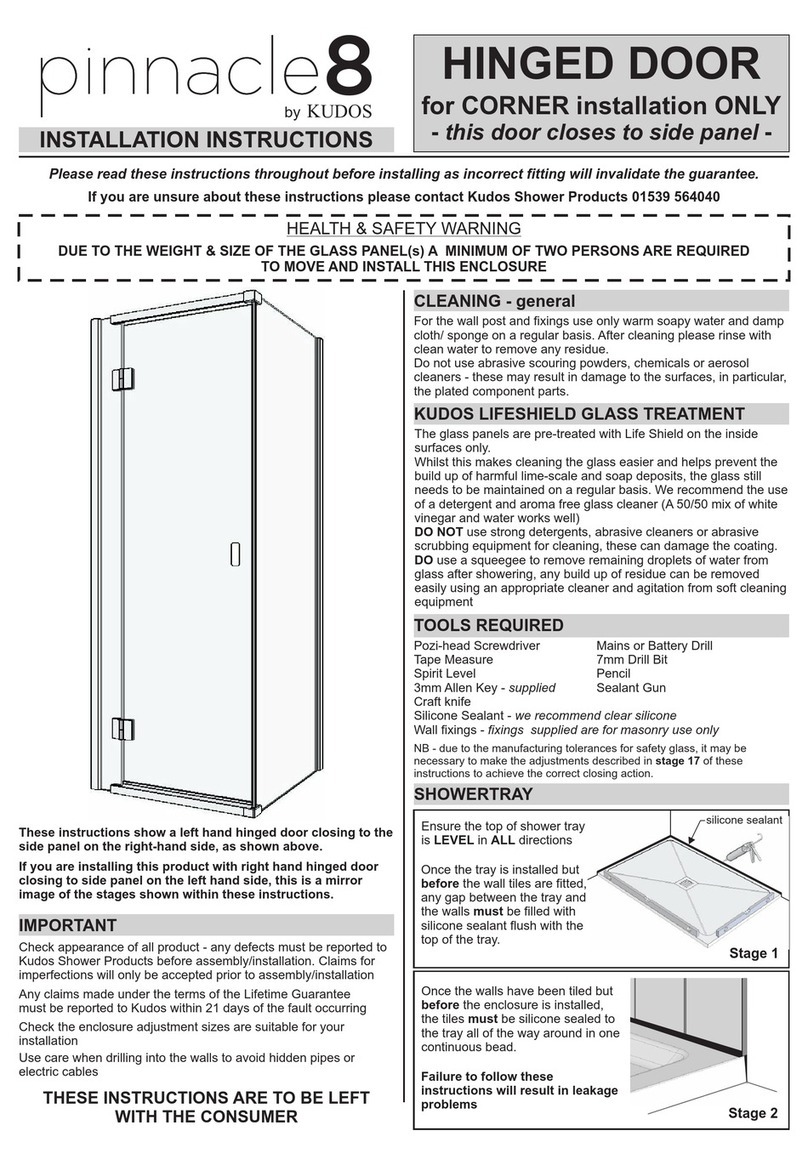

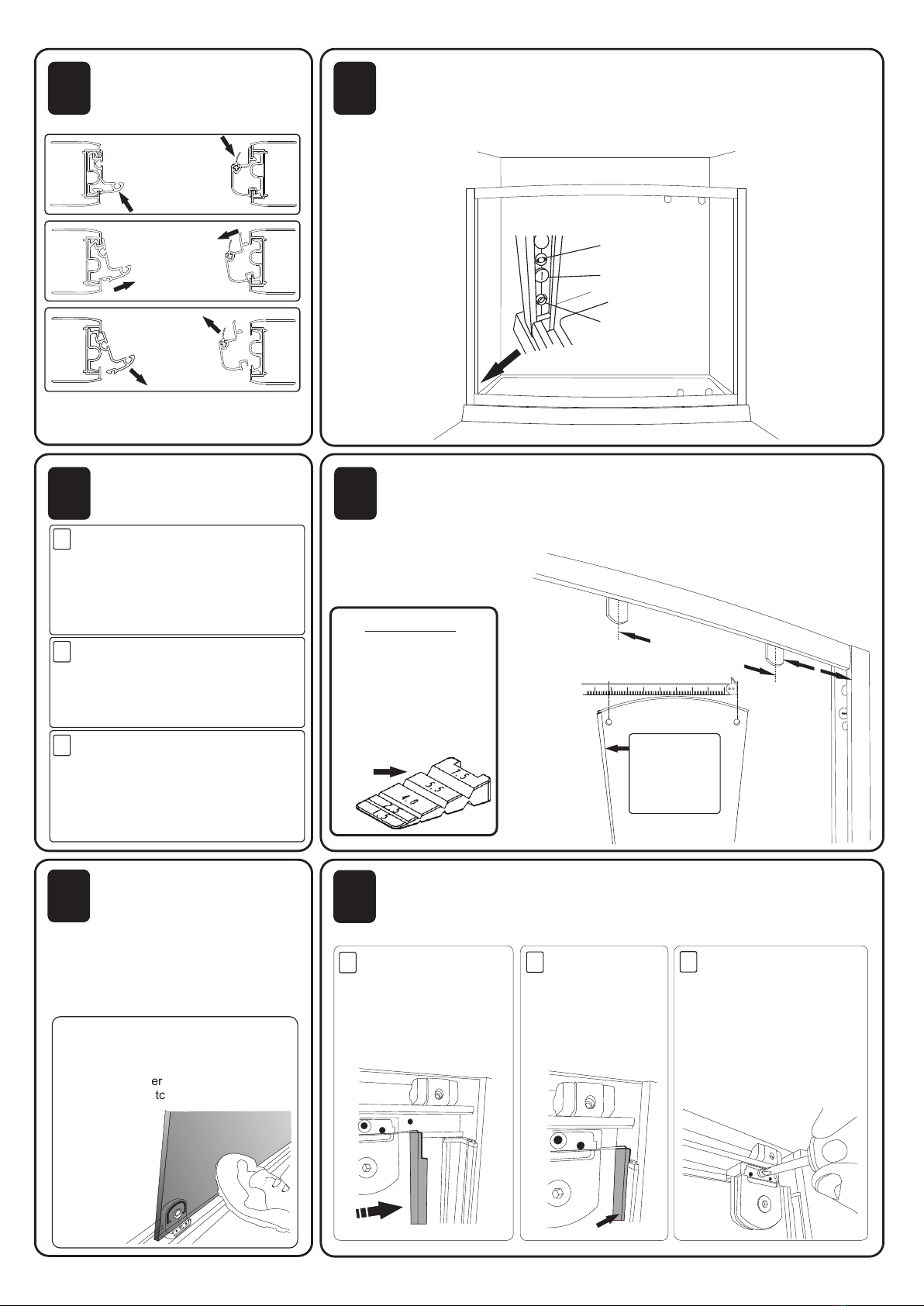

Insert spiral cam as

shown in the image

Slide the main height

adjuster block into the base

of the wall post, it will “Click”

when engaged

When fitted the

height adjuster

block should be

flush with the base

of the wall post

123

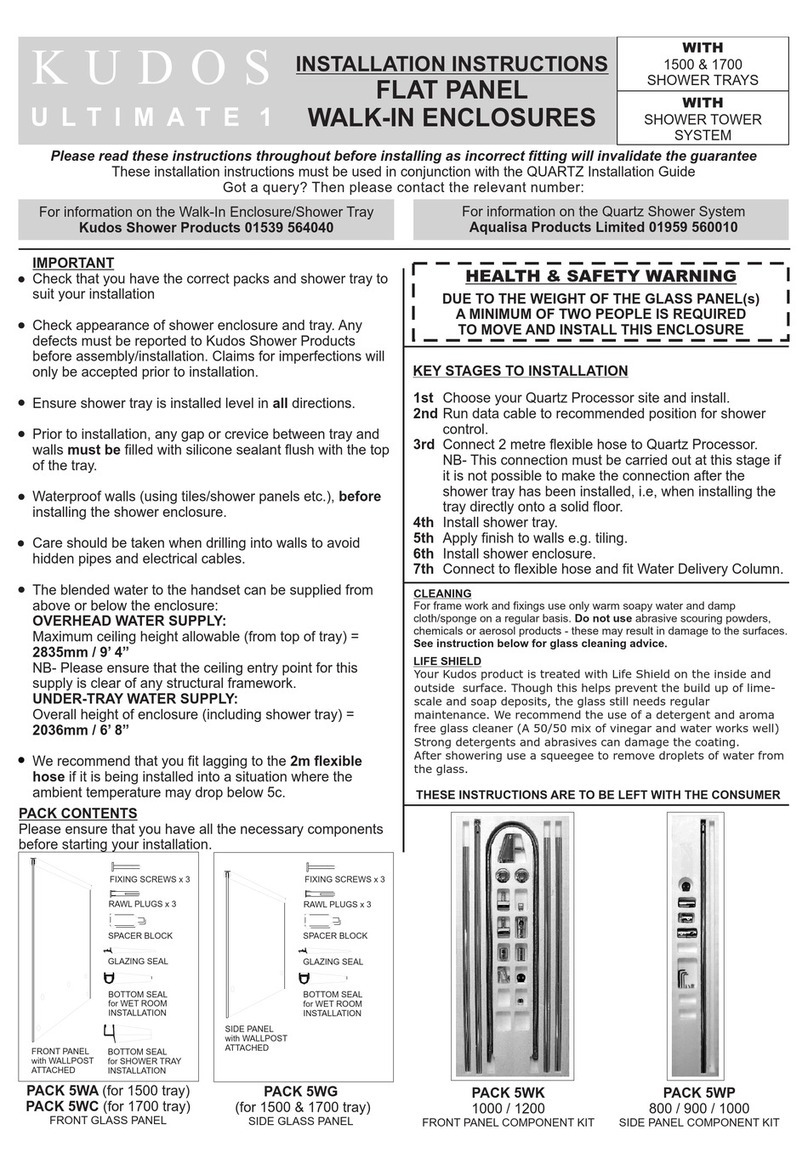

Insert the height adjustment blocks into the base of the wall posts as

shown. You will need to lift the wall post slightly to allow space to fit

the height adjustment block.

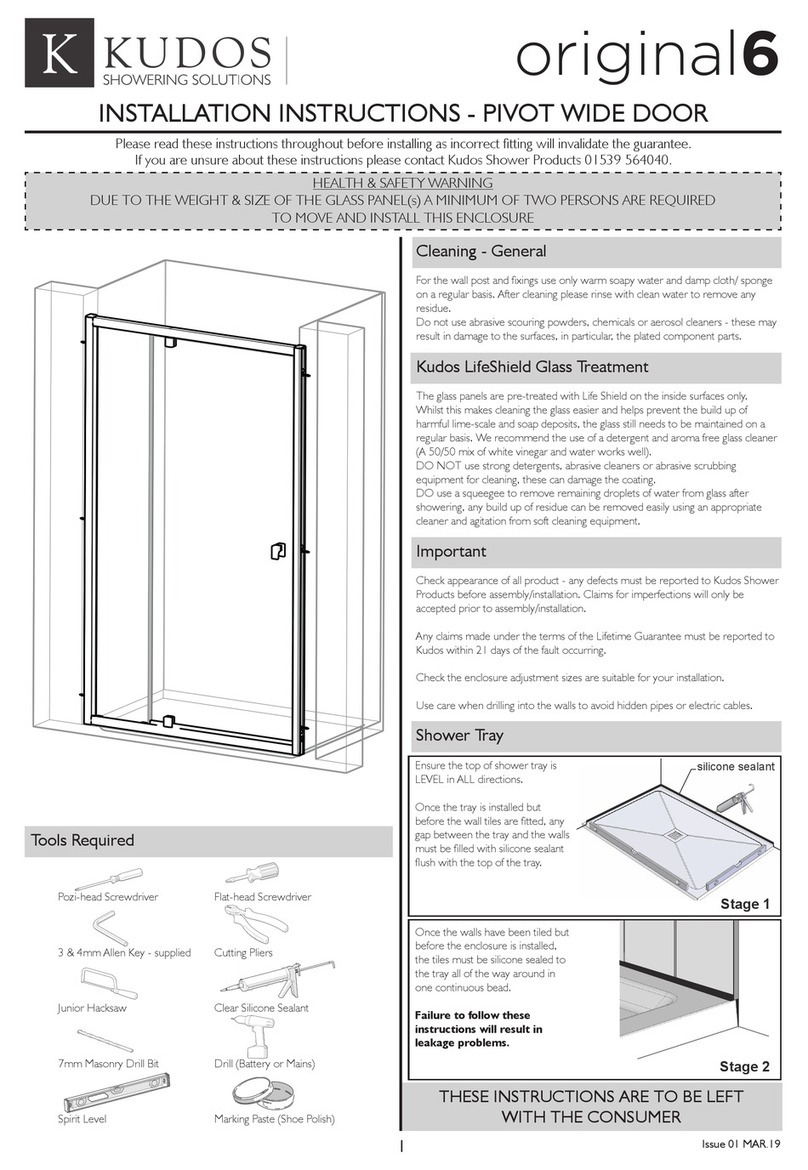

SCREW

PORTS

OPEN SIDE

FIXED PANEL

SIDE

Remove the fixed panel

patches from the fixed glass

(glass without handle) by

removing the allen key screws. Keep

the inner patch covers safe. Slide x1

Stop Block into each rail as shown,

and then x2 Fixed Panel Patches into

each rail as shown. You do not need to

secure these fixings into the rail at this

stage.

Identify both wall posts. The

wall post with the plastic

flipper seal as shown will be

the opening side of the enclosure,

the one without the seal will be the

fixed panel side. Please ensure that

the wall post without the flipper

seal is to go to the end of the rails

with the pre drilled hole as shown in

stage 4.

AT THIS STAGE REMOVE THE

CONNECTOR POSTS FROM BACK OF

WALL POSTS

VIEWED FROM ABOVE

Secure the wall posts to the

rails using the X8 No.6x30PH

screws from the screw

Assembly Pack. Please ensure that

each screw locates into the relevant

screw port in the rail as shown. We

recommend that you start with the top

rail.

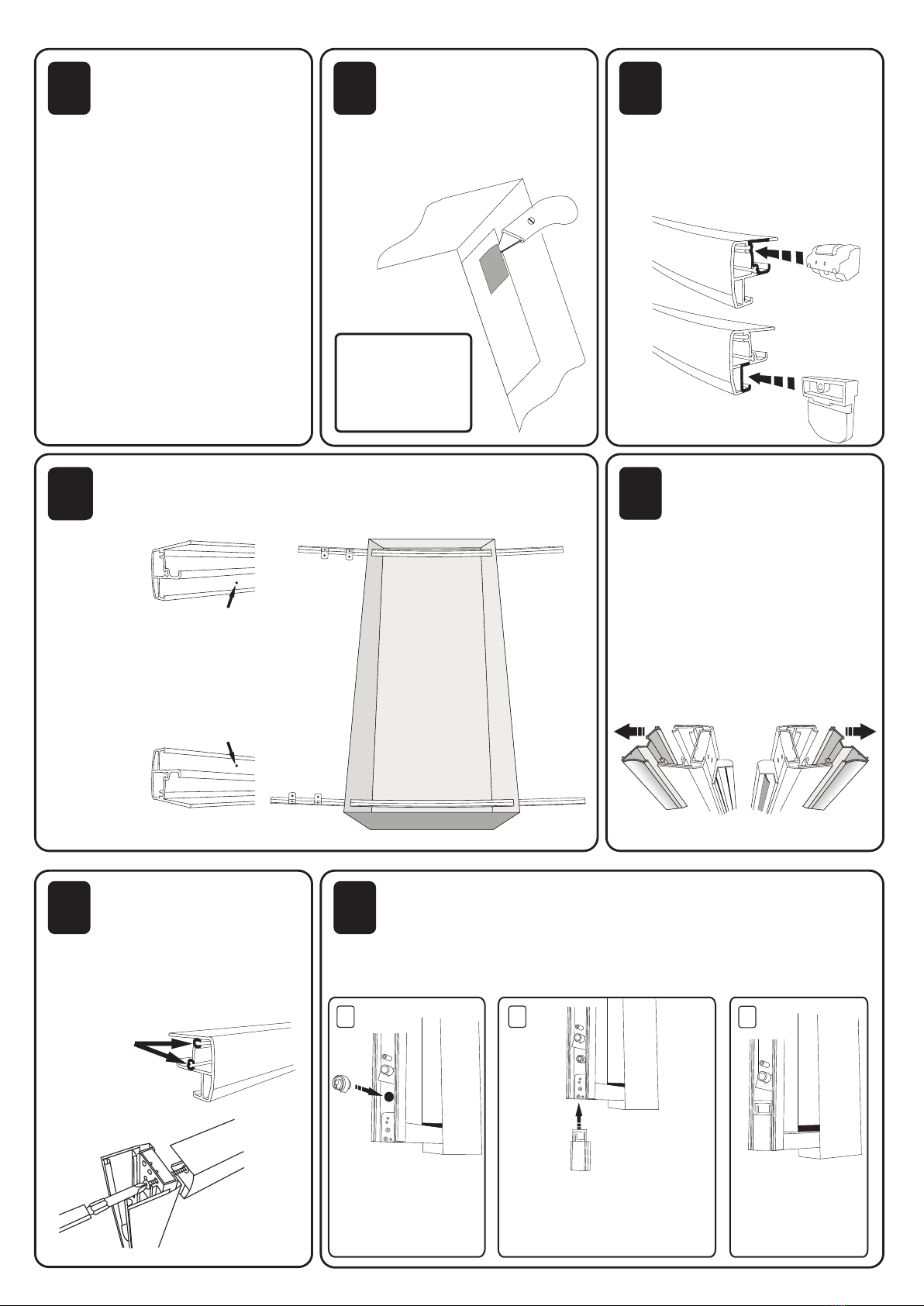

To help with assembly insert the rails through the box as shown. The

rails are handed, the fixed panel end can be identified by the pre drilled

hole at the end. These instructions show a Left Hand Entry

Cut out each end of the box

lids where shown. These

will help with the assembly

of the enclosure. If you have help

then these may not be necessary.

Ensure that the

screws are fully

tightened

This stage is best carried out

against a wall. Start off with the

top rail and ensure that the

outer face of the rail is facing

towards the wall. Please

note the Pre-Drilled hole at the

end of each rail.

X1

X2

Fixed panel patch

from fixed glass

Stop block from

installation pack

1

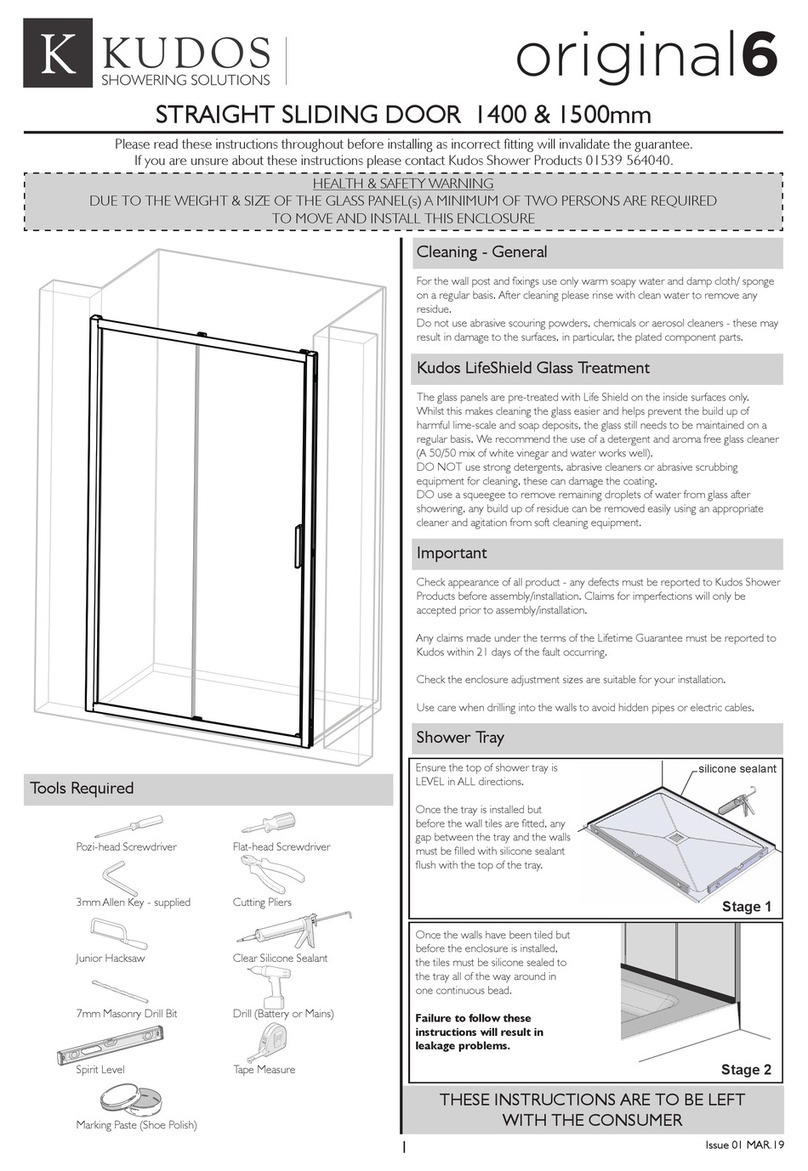

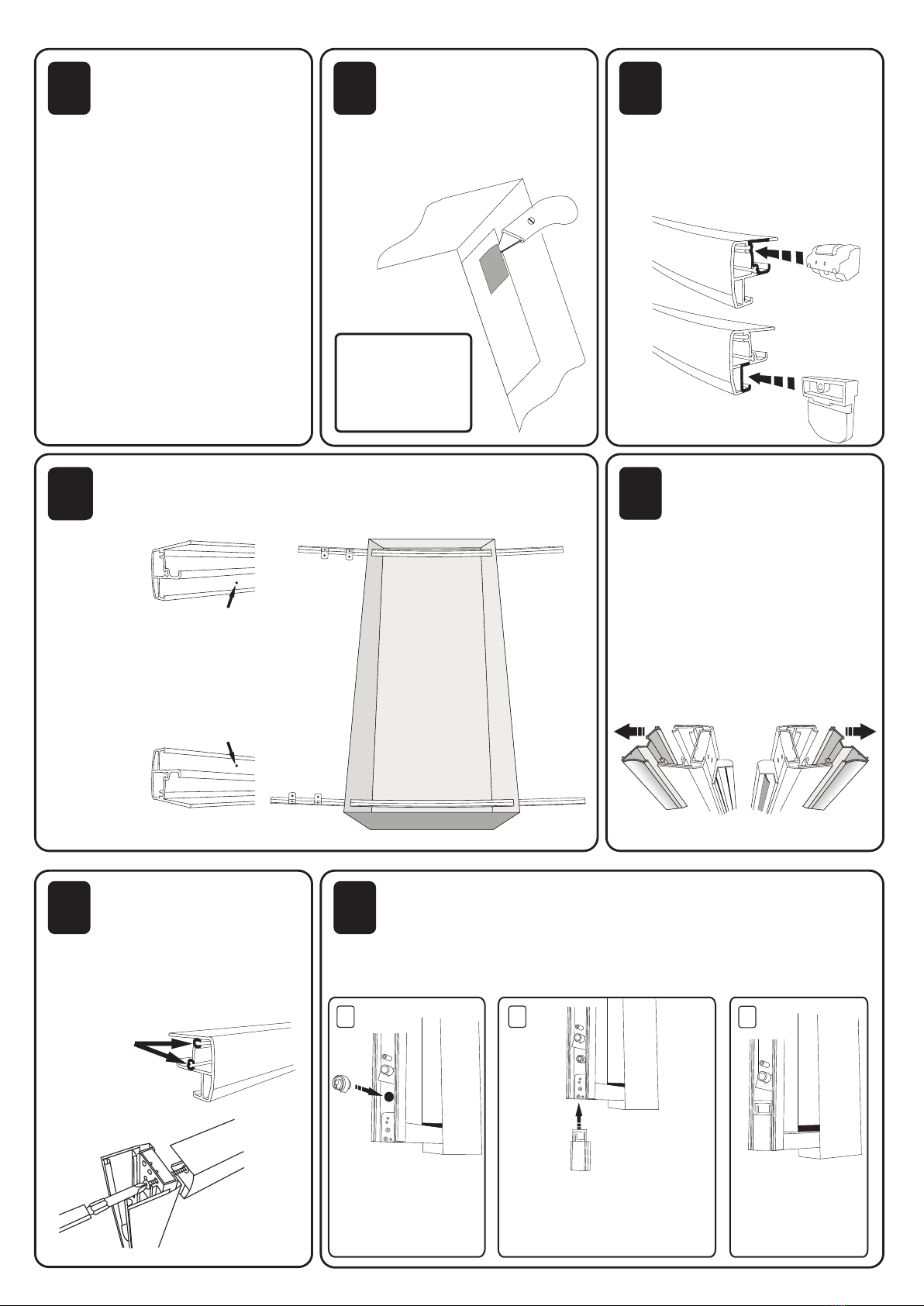

Looking at the door glass from what

would be the outside, with the

wheeled units at the top, check

which side of the door the handle is

on, this will tell you what handing the

door is, if you need to change the

handing of the door, change the

wheeled patches at the top of the

door with the quick release patches

at the bottom, along with the splash

seal. WHEELS ALWAYS TO TOP

We recommend that you then lay

something down to protect the tray

surface and position the door glass

with in the showering area at this

stage, as it can prove difficult to

move through the opening of the

enclosure at the later stages.

Check handing of door glass

then position glass in

showering area.

WE ADVISE

THAT THIS

INSTALLATION

IS CARRIED OUT

BY 2 PEOPLE

TOP

BOTTOM

CUT

HERE