3Issue 01 JUNE.21

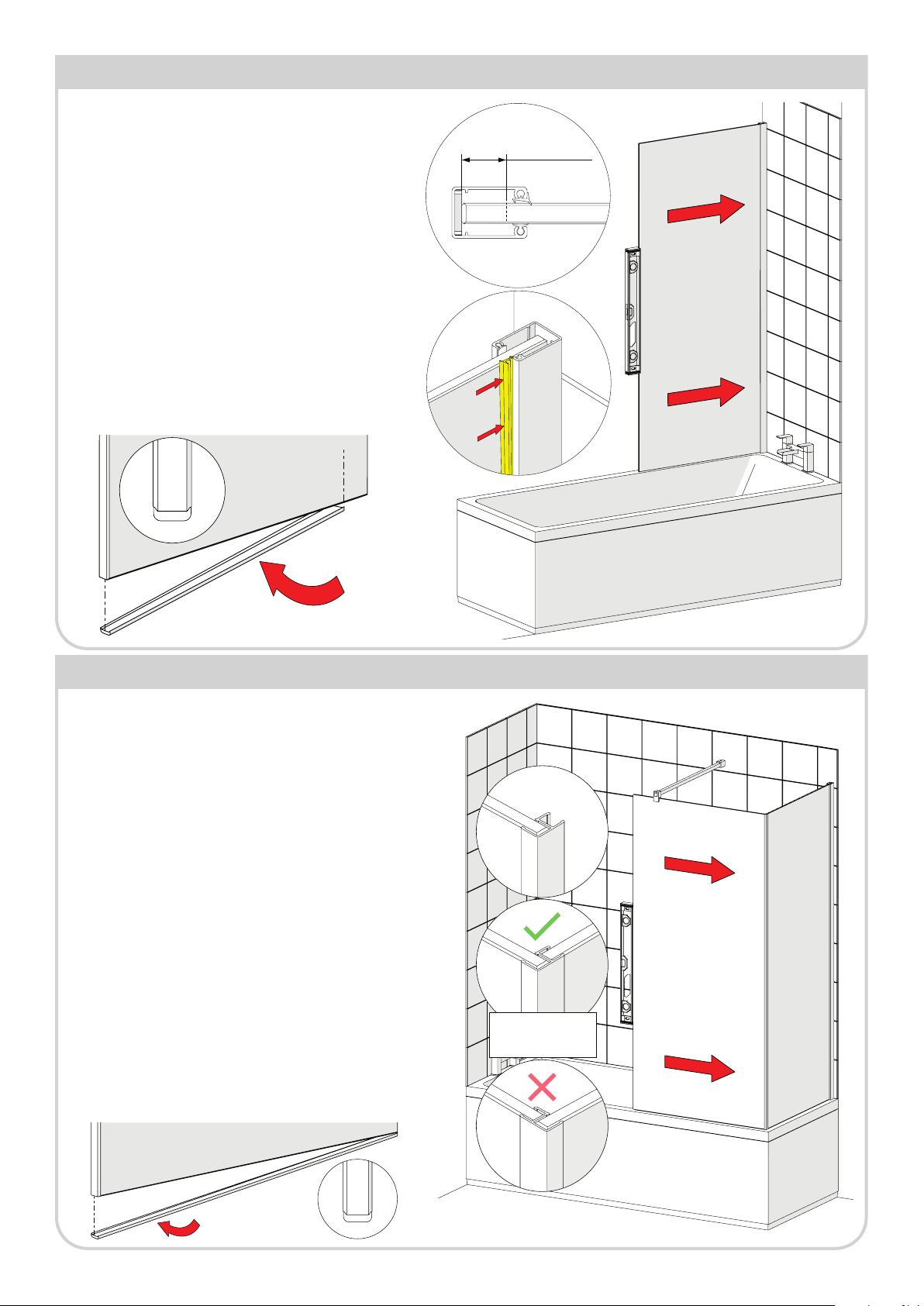

Fitting Glass Panel

1. Take note of label ‘This surface to outside’ this will determine

which is the bottom edge of your installation. Ensure that the glass

surface treated with lifesheld faces INSIDE of shower enclosure

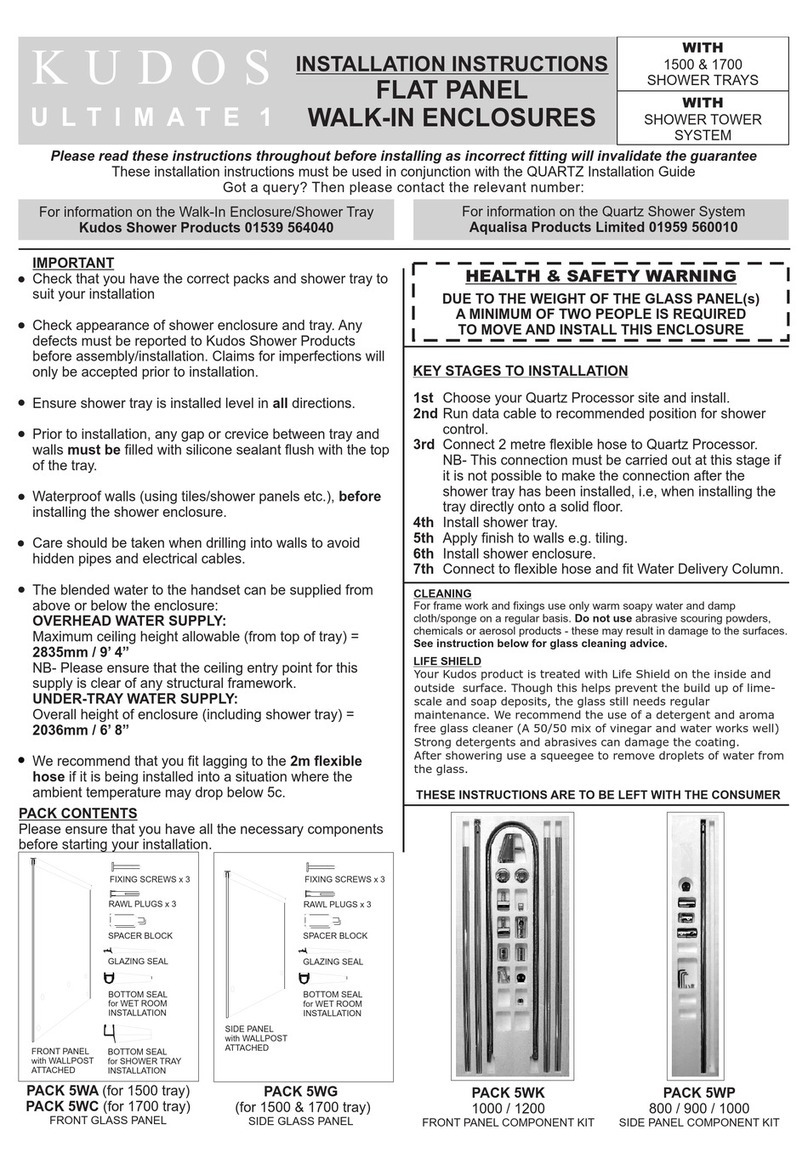

2. Acquire the Glass Trim. Cut 15mm from one end. Peel off a

small length of the bottom trim adhesive tape and apply to bottom of

glass panel 15mm from the end that will be going into the wallpost, as

shown. Continue along length of trim, peeling away the tape as you go,

until the full trim length is adhered to the panel.

Use small upturned edges on bottom trim against chamfered glass edges

to ensure trim is tted centrally.

3. Carefully t glass panel into slot in wallpost, ensuring panel is parallel

to tray edge. Ensure outer edge of in-line panel is plumb vertical, as

shown, using spirit level.

4. Secure panel by inserting glazing seal, starting from top and working

downwards, trim excess length.

If tight, lubricate glazing seal with water. Do not stretch seal when inserting,

beacuse, after cutting to length, the seal will shrink and leave a gap.

20mm

max

glass adjustment

within wallpost

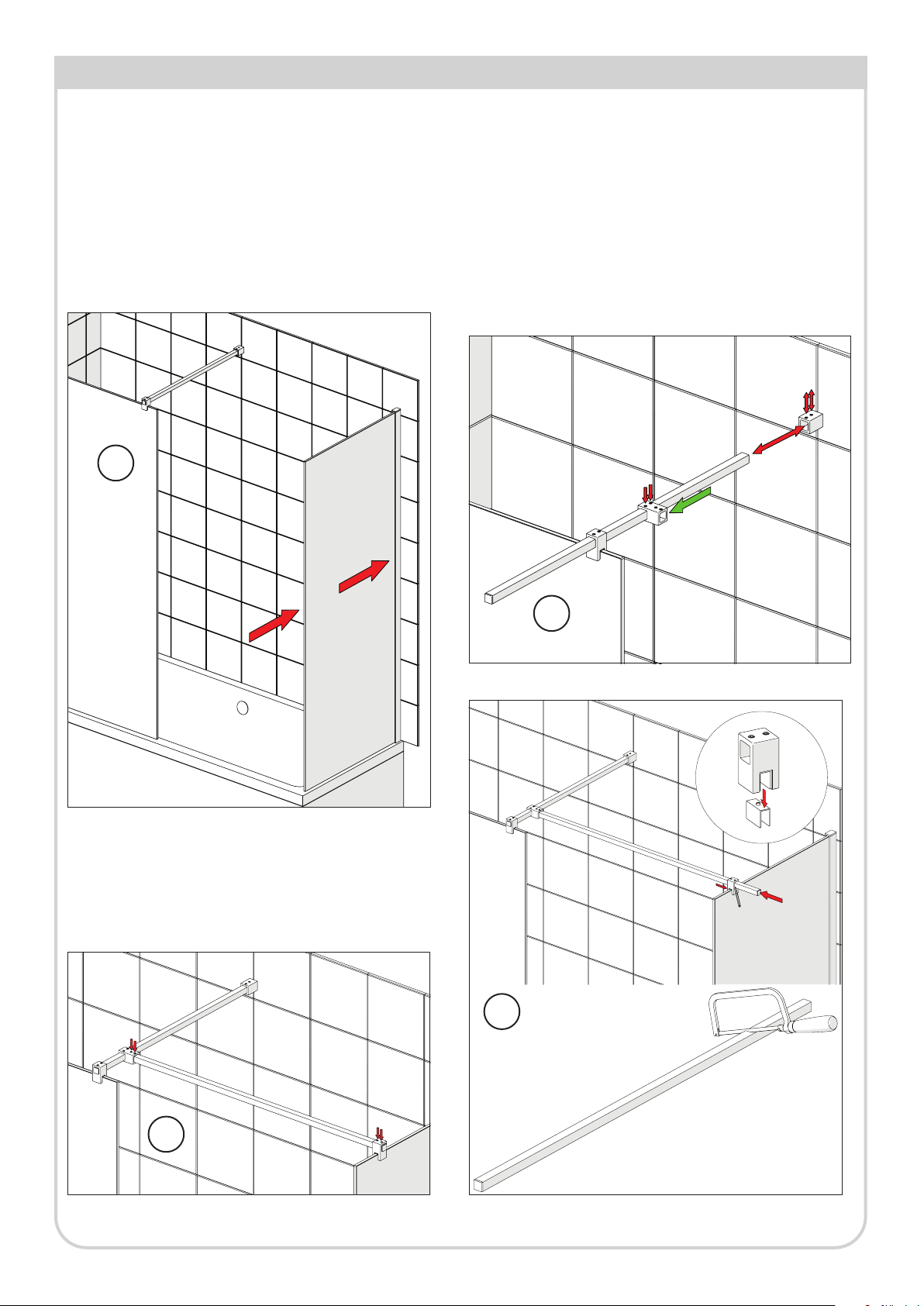

Fitting Glass to Glass Panels

1. Fit wallpost and rst panel (A) to wall, as previously described.

2. Take note of label ‘This surface to outside’ this will determine which is

the bottom edge of your installation. Ensure that the glass surface treated with

lifesheld faces INSIDE of shower enclosure

3. Acquire the Glass Trim. Peel off a small length of the bottom trim adhesive

tape and apply to bottom of glass panel from one end. Continue along length

of trim, peeling away the tape as you go, until the full trim length is adhered to

the panel.

Use small upturned edges on bottom trim against chamfered glass edges to

ensure trim is tted centrally.

4. Fit glass to glass orner seal to edge of second panel (B), ensuring seal is level

with top & bottom of glass panel.

5. Carefully offer up second panel to rst panel, ensuring the tted corner seal

lines up with edge of rst panel at the bottom.

6. Ensuring second panel is square to rst panel, push t corner seal onto

edge of rst panel. Corner seal must be fully inserted onto both panels.

7. Fit front panel component pack to second panel (B). See next page.

If tight, lubricate the corner seal of glass edges with a damp CLEAN cloth to ease

fitment - the water will evaporate over a short period. DO NOT USE silicone

spray or any other substance other than water, these will not fully dry out and will

compromise the grip and rigidty of the joint.

Front Panel ‘B’

always in front of

side panel ‘A’

Inside view Inside view