4Issue 01 MAR.19

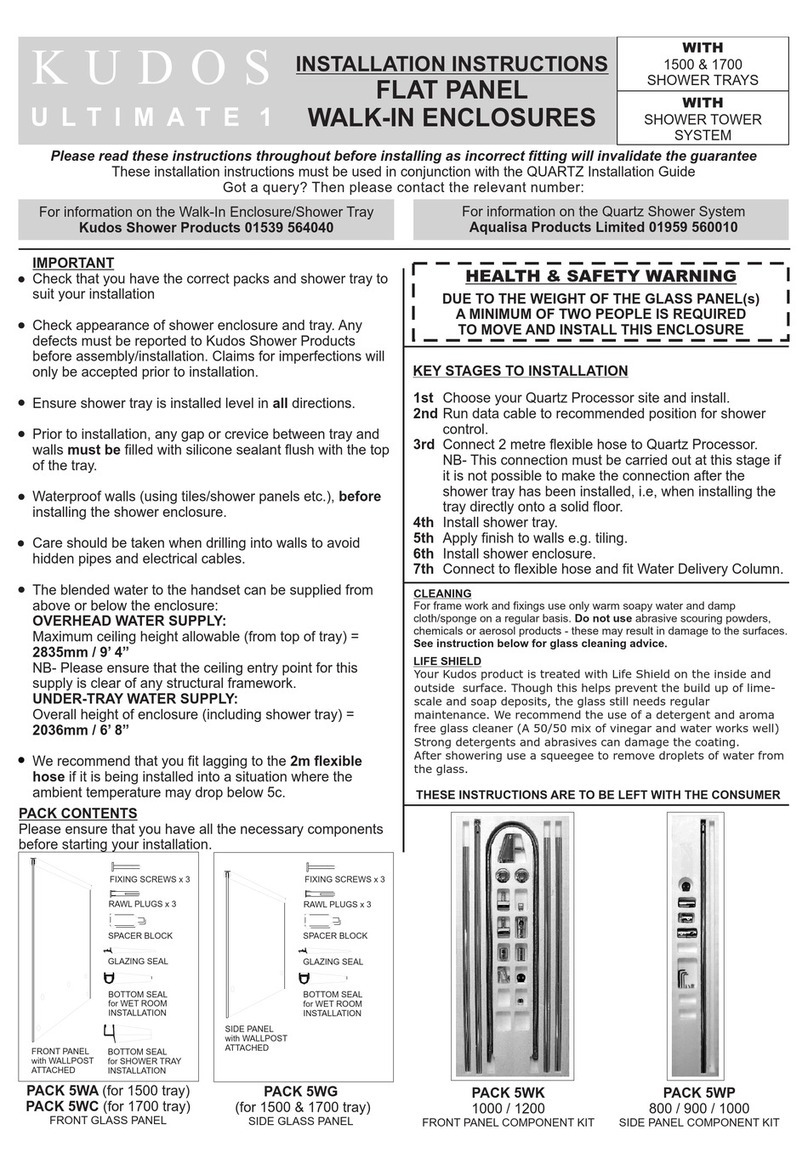

Step 14 - Re-t Fixed Glass Panel

Step 15 - Fit Seal to Fixed Glass Panel

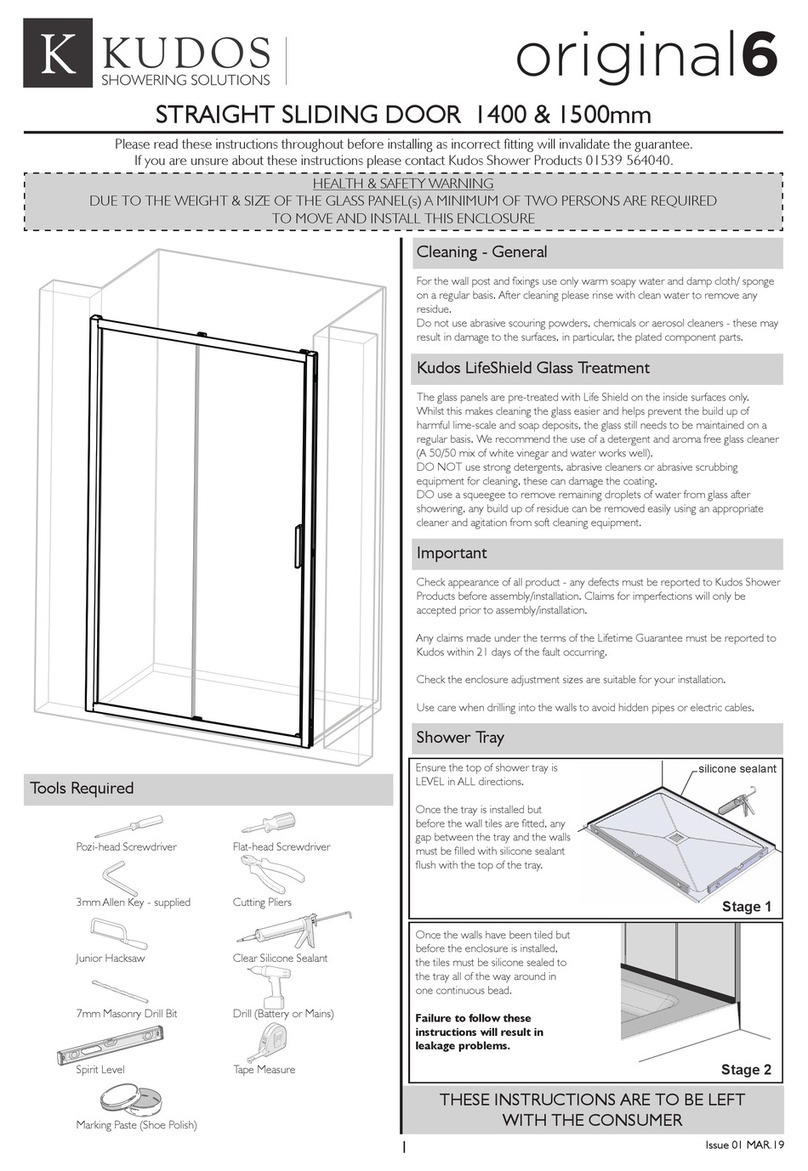

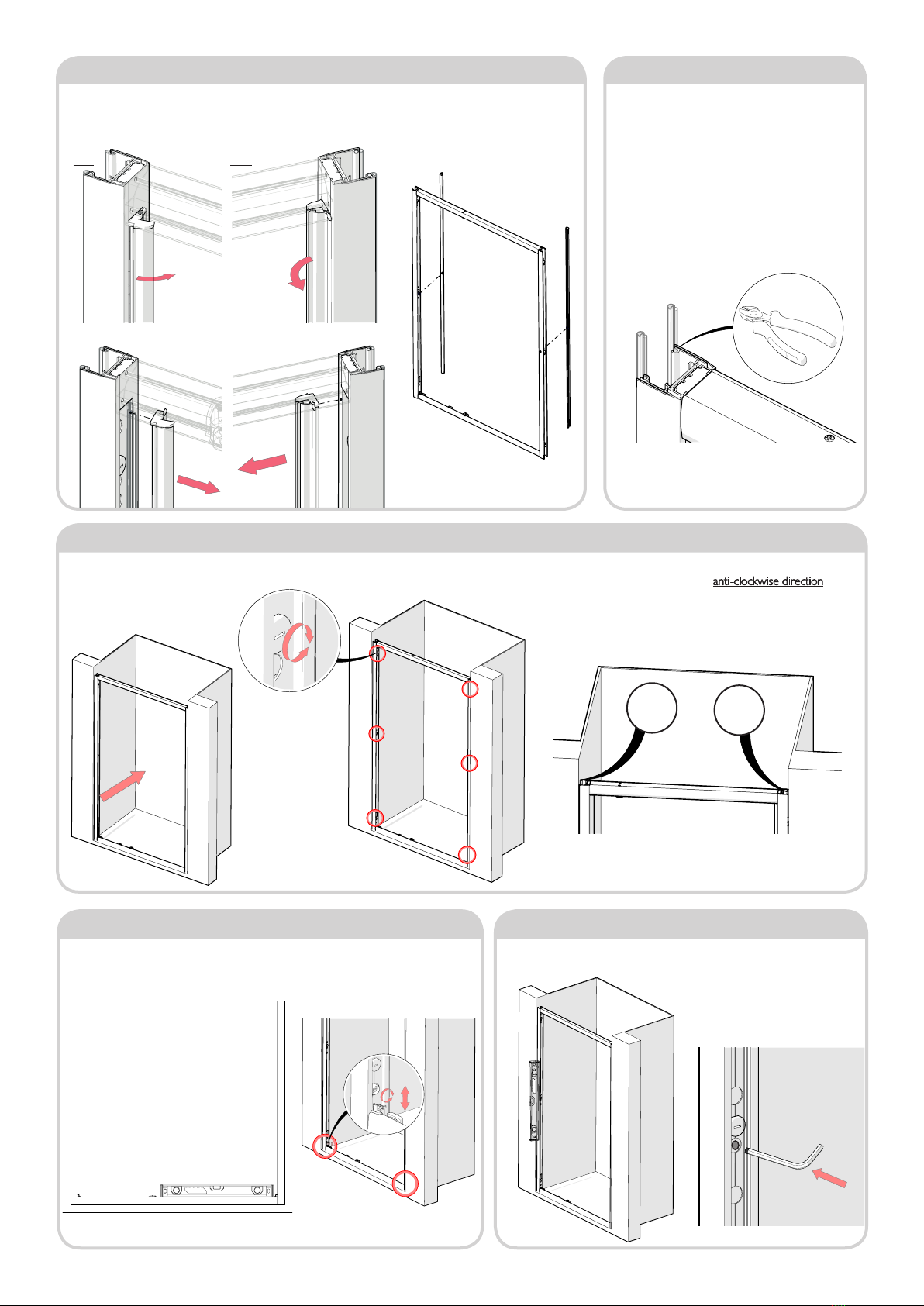

Step 10 - Drill Mounting Holes & Insert Wall Plugs

1. Remove the frame from the recess,

loosening the adjustment screws along each

side if required (do not adjust the bottom

height adjustment screws). Placing safely off

to one-side.

2. Using a 7mm masonry drill bit and drill

(or appropriate drill bit if drilling tiles), drill

six holes using the ‘spot’ marks from step 8,

each hole should be 45mm in depth.

3. Insert the six ‘6mm Wall Plugs’ into the

six holes.

Step 11 - Fitting the Frame

1. Insert the frame back into position, tighten the adjustment screws once

again until the frame is even in the gap and held fast. Using a spirit level,

check that the frame is ‘plumb’ vertical and the holes in the frame line up

with the plugs in the wall. Ensure that the frame is not twisted or buckled

and square on all sides.

2. Using 6 x No.8 Pan-head 60mm screws provided, screw the frame to

the wall on each side. Be sure not to over tighten the middle screws (nger

tighten only) as this may cause “bowing” of the door frame. Using the ‘clip-

in’ extrusions as a straight edge, rest the straight edge against edge side of

the frame, you’ll be able to see any bowing that may have occurred. The

middle screws may now be adjusted to assist in plumbing the door frame

and removing the “bow.”

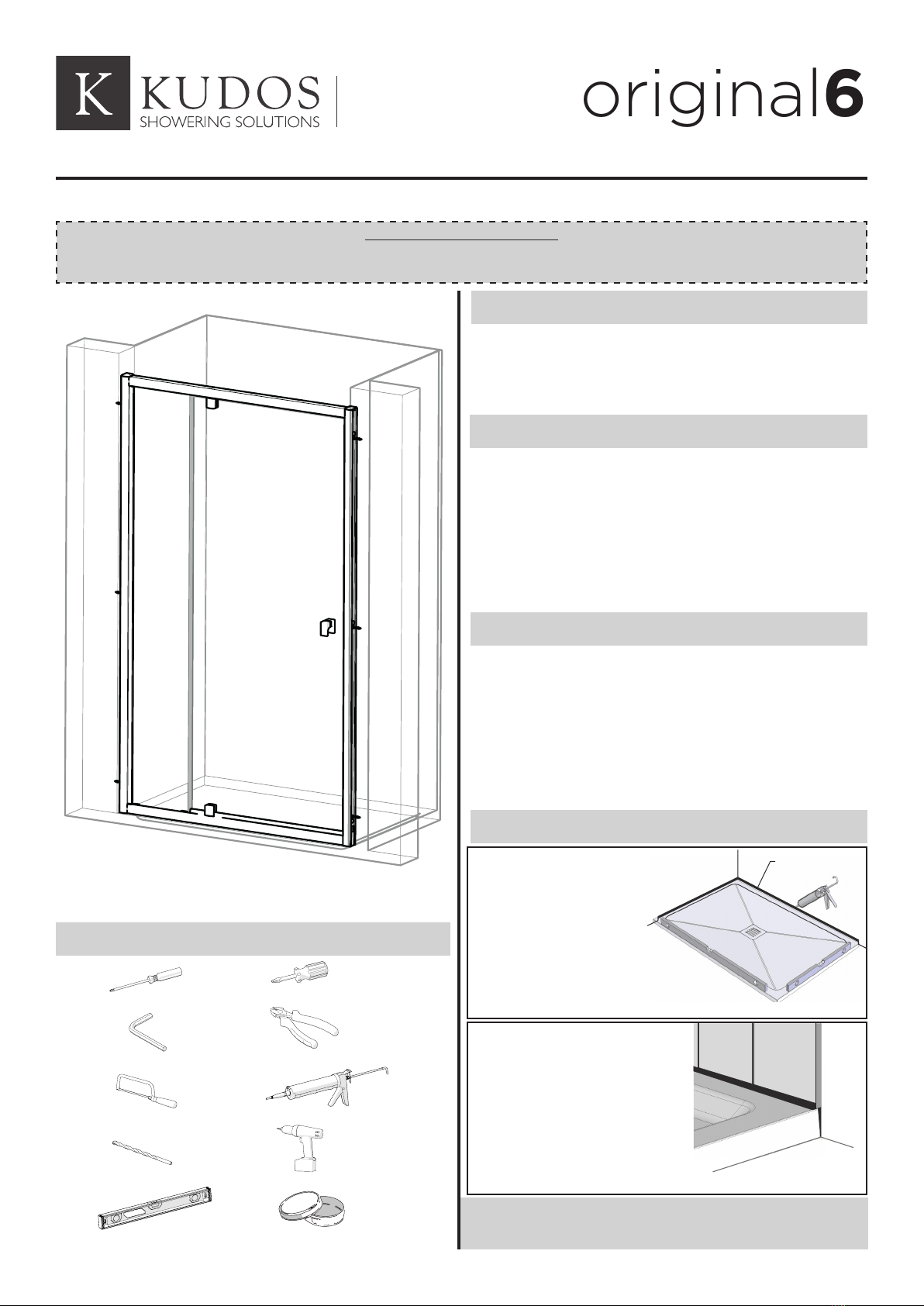

Step 12 - Re-t Clip-In Extrusions

1. Re-t clip-in extrusions, which were removed in stage 4. The clip-in extrusion with

“ipper seal” should be on the handle side of door. Ensure the leading edge is properly

located along the full height before pressing the clip-in extrusion into the door frame, it

will not locate properly if twisted.

1. Re-t the xed panel glass, carefully t glass panel into slot in wall-post,

ensuring panel is square to wall. Tap the plastic prole rmly into groove of

clip-in extrusion along full length, if this is not done, the xed panel glass may

interfere with the door glass when this is installed.

1. Uncoil the ‘Glazing Wedge Seal (PlexF05),’ Insert the seal to the outside

of the enclosure, between the xed glass panel and lip of the metal frame.

Ensure that the glass surface treated with LIFESHIELD faces to INSIDE of

shower enclosure - see label on glass. Inserting the glazing seal, starting at top

and working downwards, trim excess length. If tight, lubricate glazing seal with

water. Do not stretch seal when inserting, because, after cutting to length, the

seal will shrink and leave a gap.

If the seal is misshapen, soak in warm water, not boiling, for 2-3 minutes prior

to use.

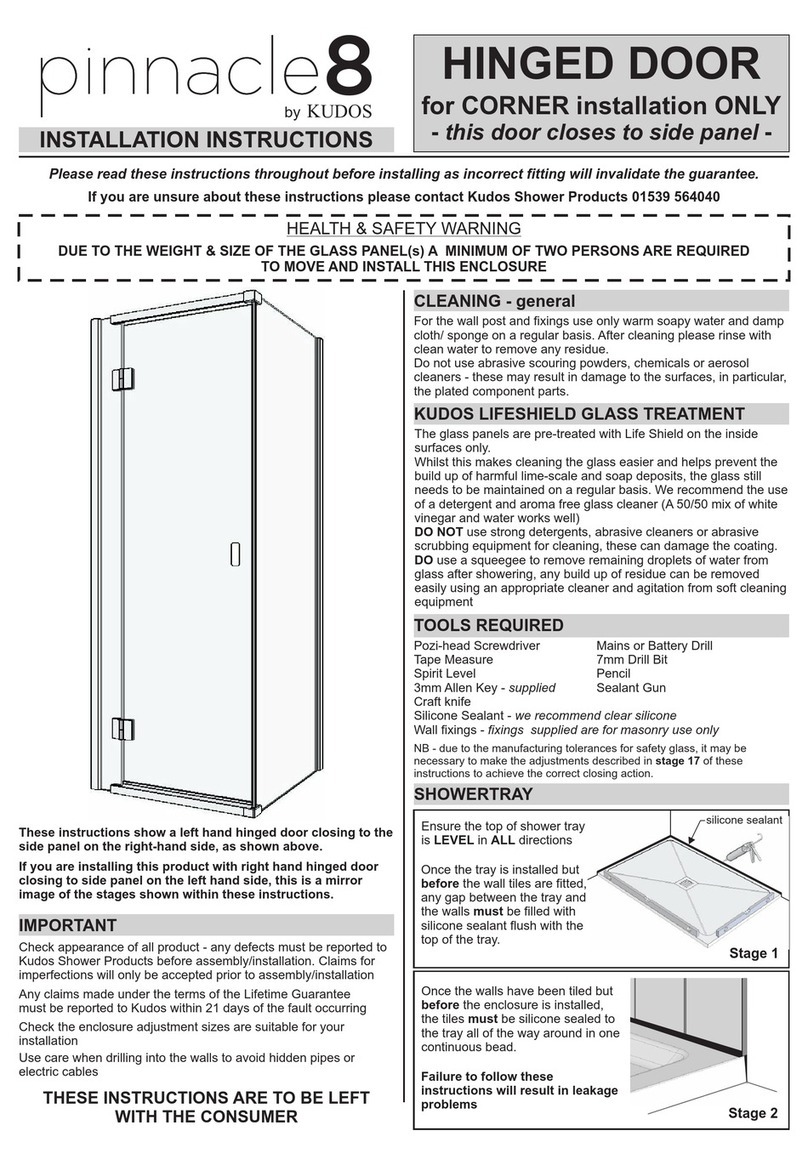

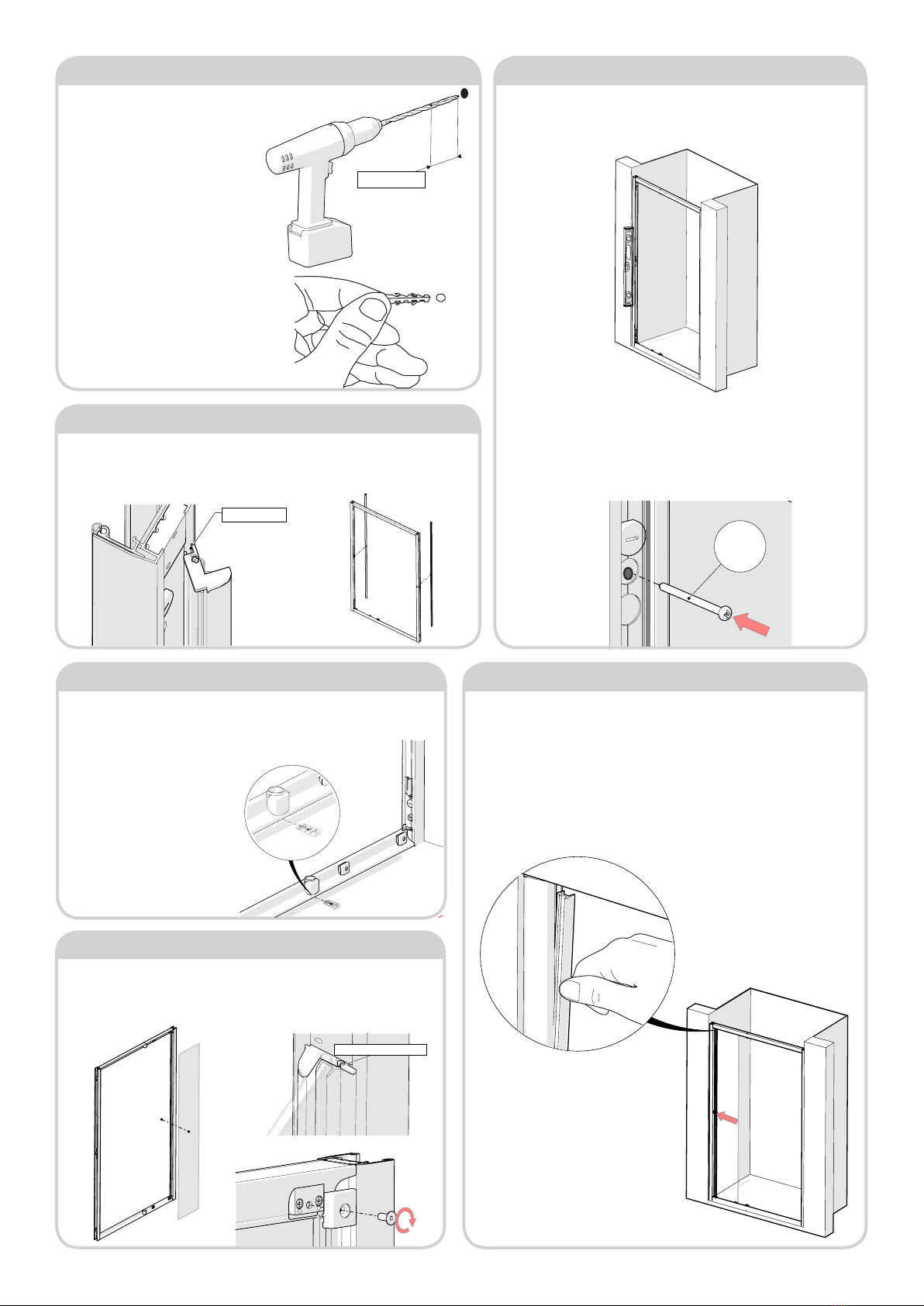

Step 13 - Shim Frame

1. Often shower trays have

different angled top faces, in order

to help keep the frame supported

use the ‘Shim (M97-01)’ supplied.

On the inside of the enclosure

measure the gap between the

bottom of the rail and top of the

tray, select the height required from

the shim strip supplied, break off

and insert under rail at pivot body

position . This will support rail when

glass is tted. The shim will be

concealed by silicone sealant later.

2. Tighten xing bolts until the panel is secure.

Locate Plastic Profile in

45mm Deep