EGF8 Grabber 3 Kuhns Manufacturing (877-296-5851)

CONTENTS

1. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Intended Usage . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Operator Orientation. . . . . . . . . . . . . . . . . . . . 4

1.3 Specifi cations . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Serial Number Location . . . . . . . . . . . . . . . . . 4

1.5 Owner/Operator Manual Storage . . . . . . . . . . 4

1.6 Product Improvements . . . . . . . . . . . . . . . . . . 5

1.7 Disposal of Equipment at End of Useful Life . 5

1.8 Unanswered Questions . . . . . . . . . . . . . . . . . 5

2. SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Safety Alert Symbol . . . . . . . . . . . . . . . . . . . .6

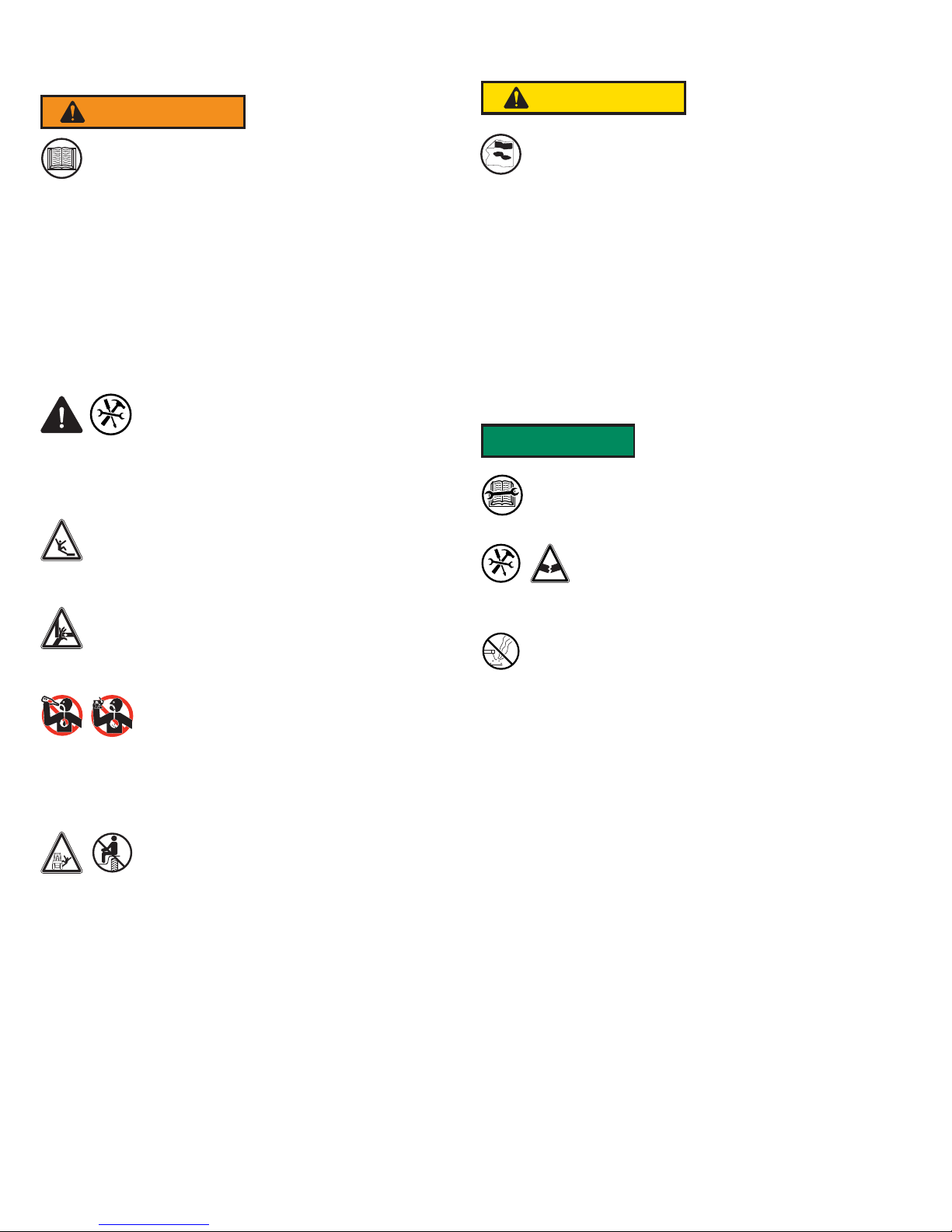

2.3 Safety Icons Nomenclature . . . . . . . . . . . . . . 7

2.3.1 Personal Protection/Important

Information . . . . . . . . . . . . . . . . . . . .7

2.3.2 Prohibited Actions . . . . . . . . . . . . . . .7

2.3.3 Hazard Avoidance . . . . . . . . . . . . . . .7

2.4 General Operating Safety. . . . . . . . . . . . . . . . 8

2.5 Safety Signs . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6 Practice Safe Maintenance . . . . . . . . . . . . . . 8

2.7 Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.8 Hydraulic Safety . . . . . . . . . . . . . . . . . . . . . . . 9

2.9 Sign-Off Form . . . . . . . . . . . . . . . . . . . . . . . . 9

2.10 Operation Safety . . . . . . . . . . . . . . . . . . . . . 11

2.11 Transporting Safety . . . . . . . . . . . . . . . . . . . 11

2.12 Storage Safety . . . . . . . . . . . . . . . . . . . . . . . 11

2.13 Maintenance Safety . . . . . . . . . . . . . . . . . . . 11

3. SAFETY SIGNS AND LABELS . . . . . . . . . . . . . 12

3.1 General Information . . . . . . . . . . . . . . . . . . . 12

3.2 Contact Information . . . . . . . . . . . . . . . . . . . 12

3.3 How to Install Replacement Safety Signs . . 12

3.4 Safety Sign Locations. . . . . . . . . . . . . . . . . . 13

3.5 Safety Signs . . . . . . . . . . . . . . . . . . . . . . . . . 13

4. NOMENCLATURE . . . . . . . . . . . . . . . . . . . . . . . 14

5. OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 User Safety Training. . . . . . . . . . . . . . . . . . . 15

5.2 Tractor Requirements. . . . . . . . . . . . . . . . . . 15

5.2.1 Equipment and Capabilities. . . . . . . 15

5.2.2 Tractor Safety Devices . . . . . . . . . . 15

5.2.3 ROPS and Seat Belt . . . . . . . . . . . . 16

5.3 Pre-Operation Checklist . . . . . . . . . . . . . . . 16

5.4 Attaching to Loader . . . . . . . . . . . . . . . . . . . 16

5.5 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.5.1 Adjustable Crowd Bar . . . . . . . . . . . 17

5.6 Field Operation. . . . . . . . . . . . . . . . . . . . . . .17

5.7 Detaching From Loader . . . . . . . . . . . . . . . . 18

6. TRANSPORTING. . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1 General Safety . . . . . . . . . . . . . . . . . . . . . . . 19

6.2 Highway and Transport Operations . . . . . . . 19

6.3 Pre-transport Checklist. . . . . . . . . . . . . . . . . 19

7. STORAGE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.1 Placing in Storage . . . . . . . . . . . . . . . . . . . . 20

7.2 Removing from Storage . . . . . . . . . . . . . . . . 20

8. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . 21

8.1 Maintenance Safety . . . . . . . . . . . . . . . . . . . 21

8.2 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8.3 Bolt Torque Requirements . . . . . . . . . . . . . . 22

8.3.1 Standard Torque Values . . . . . . . . . 22

8.4 Welding Repairs. . . . . . . . . . . . . . . . . . . . . . 22

8.5 Service Record . . . . . . . . . . . . . . . . . . . . . .23

9. PARTS SECTION. . . . . . . . . . . . . . . . . . . . . . . . . 24

9.1 Ordering Parts . . . . . . . . . . . . . . . . . . . . . . . 24

9.2 Contact Information . . . . . . . . . . . . . . . . . . . 24

9.3 Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9.4 Parts Detail. . . . . . . . . . . . . . . . . . . . . . . . . . 25