Kuhns Manufacturing (877) 296-5851 3 Tie Grabber

CONTENTS

1. INTRODUCTION ..........................4

1.1 Intended Usage .......................4

1.2 Operator Orientation....................4

1.3 Warranty .............................4

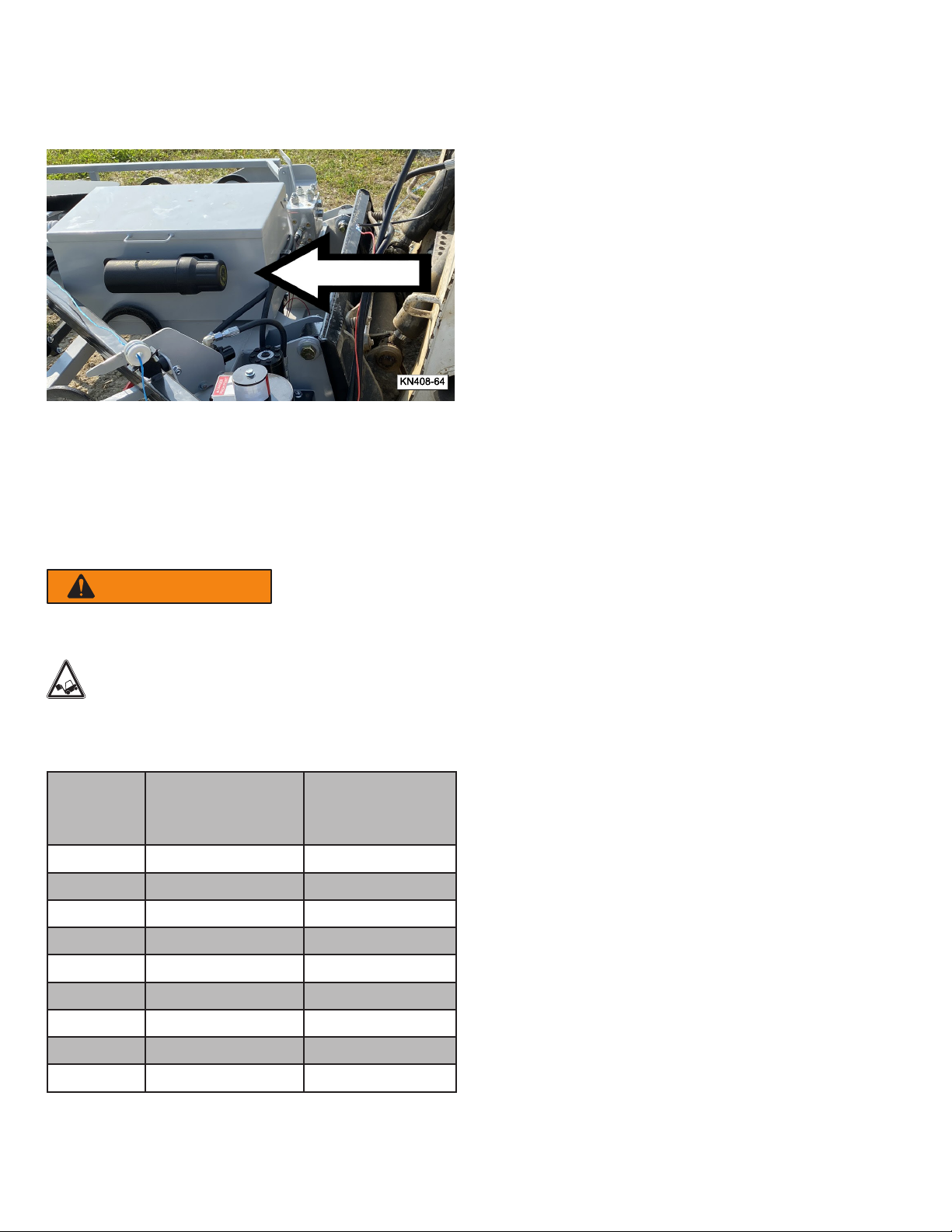

1.4 Serial Number Location .................4

1.5 Owner’s Manual Storage ................5

1.6 Specifications .........................5

1.7 Definitions............................5

1.8 Product Improvements ..................5

1.9 Disposal of Equipment at End of Useful Life . 5

1.10 Unanswered Questions .................5

2. SAFETY .................................6

2.1 General..............................6

2.2 Safety Alert Symbols ...................6

2.3 Safety Icons Nomenclature ..............6

2.4 Prohibited Actions......................7

2.5 Personal Protection/Important Information ...7

2.6 Hazard Avoidance......................7

2.7 General Operating Safety................8

2.8 Machine’s Owner/Operator Manual ........8

2.9 Machine’s Safety Device Requirements.....8

2.10 Practice Safe Maintenance...............9

2.11 Training..............................9

2.12 Sign-Off Form ........................11

3. SAFETY SIGNS AND LOCATIONS ..........12

3.1 General Information ...................14

3.2 Safety Signs and Labels................14

3.3 Safety Signs and Instructional Labels .....14

3.4 How to Install Replacement Safety Signs...14

4. LIFTING AND HANDLING ..................15

4.1 Lifting points .........................15

4.2 Transporting .........................15

4.3 Highway and Transport Operations .......15

4.4 Pre-transport Checklist .................15

5. TIE GRABBER ATTACHMENT ..............16

5.1 Bracket Attachment ...................16

5.2 Hydraulic Safety ......................16

5.3 Hydraulic Connections .................16

6. CONNECTING HOSES TO MACHINE........17

6.1 One Circuit System (Two Hose Method) ...17

6.2 Two Circuit System (Four Hose Method) ...17

6.3 System Change Over ..................18

7. THREADING TWINE INTO THE TWINE ARM..20

8. OPERATION .............................22

8.1 Operation Safety......................22

8.2 Pre-Operation .......................22

8.3 Tie Grabber Operation .................22

8.4 Knotter Operation .....................24

9. MANIFOLD PORT LOCATIONS AND IDENTIFICA-

TION ......................................25

10. SETTING AND TIMING ....................28

10.1 Accessing the Knotter Components .......28

10.2 Knife Arm ...........................28

10.3 Testing and Adjusting Knotter Assembly....29

10.4 Twine Disc Assembly ..................31

10.5 Cam Timing Mark .....................31

10.6 Tucker Finger ........................32

10.7 Knotter Drive Chain ...................32

10.8 Twine Arm Drive Chain .................32

10.9 Twine Tensioner ......................32

11. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . 33

11.1 Maintenance Safety ...................33

11.2 General Information ...................35

11.4 Twine Arm...........................35

11.5 Squeeze Arm ........................35

11.6 Knotter .............................35

11.7 Chain Lubrication .....................35

11.8 Hydraulic Hoses ......................35

11.9 Flow Control Valve Plunger .............36

11.10 Springs .............................36

12.

MAINTENANCE SERVICE SCHEDULE SHEET

...37

12.1 Torque Requirements ..................38

13. STORAGE...............................39

13.1 Placing in Storage ....................39

14. TROUBLESHOOTING .....................40

15. PARTS .................................43

15.1 Main Tie Grabber Assembly .............43

15.2 Hooks ..............................44

15.3 Squeeze Arm Assembly ................45

15.4 Twine Arm Stack......................46

15.5 Twine Arm Motor Group ................47

15.6 Manifold Assembly ....................48

15.7 Twine Box Assembly...................49

15.8 Plunger Valve Assembly ................50

15.9 Knotter Main Assembly.................51

15.10Knotter Motor Group...................53