FENDT FORMER 12545 PRO User manual

FORMER

AGCO GmbH ·Fellastraße 1-3 ·D-90537 Feucht

© AGCO

07.2019

12545 PRO

FCL 025001

Operator's Manual

Rotary rake

FENDT is a worldwide brand of AGCO

Original Operator's Manual

FEL16917904_EN02

English

FORMER 12545 PRO 1

This Operator's Manual describes all equipment and variants, including optional equipment

that is not supplied in the standard scope of delivery.

Customers cannot derive any claims regarding the equipment of machines that have been

supplied or are to be supplied on the basis of this description.

Our machines undergo continuous further development. All technical details and illustrations

in this Operator's Manual are therefore non-binding and we reserve the right to make

changes.

Legal notice

Document type: Operator's Manual

Product: Rotary rake

Model: FORMER 12545 PRO

Language: EN – English

Publication status: 07 2019

Address: AGCO GmbH

Fellastraße 1-3

90537 Feucht

Germany

© Copyright by AGCO GmbH

All parts of this documentation are protected by copyright.

Any use beyond that permitted by copyright law requires the written consent of AGCO

GmbH. This applies in particular to the reproduction, distribution and translation of this docu-

mentation or parts thereof and for the storage and processing of the content with electronic

data processing systems.

2 FORMER 12545 PRO

Contents

1.1Warranty and liability 5

1.2Conventions 5

1.2.1Illustrations 5

1.2.2Pictograms used 5

1.2.3Text symbols 5

1.2.4Abbreviations 5

1.3Other applicable documentation 5

1.4Storage of documentation 6

1.5Applicability of the Operator's Manual 6

1.6Sign plate and serial number 6

1.7EU Declaration of Conformity 7

2.1Intended use 8

2.2Reasonably foreseeable misuse 8

2.3User qualifications 8

2.4Warning notices 8

2.4.1Warning notices in the Operator's Manual 8

2.4.2Warning notices on the machine 9

2.5Safety instructions 10

2.5.1Operating and maintenance personnel 10

2.5.2Protective work wear 11

2.5.3Personal protective equipment 11

2.5.4Preparing the machine for use 11

2.5.5Coupling/uncoupling the machine to/from the tractor 11

2.5.6Machine operation 11

2.5.7Driving on public roads and lanes 11

2.5.8Maintenance work 12

2.5.9Working with hydraulics 12

2.5.10Work in the vicinity of high-voltage power lines 12

2.5.11Unauthorized modifications or alterations 12

2.5.12What to do in an emergency 12

2.5.13Fire prevention 12

3.1Product features 14

3.2Machine positions 14

3.2.1Transport position 14

3.2.2Working position 14

3.2.3Headland position 14

3.2.4Parking position 14

3.3Notices on the machine 14

3.4Machine components 15

FORMER 12545 PRO 3

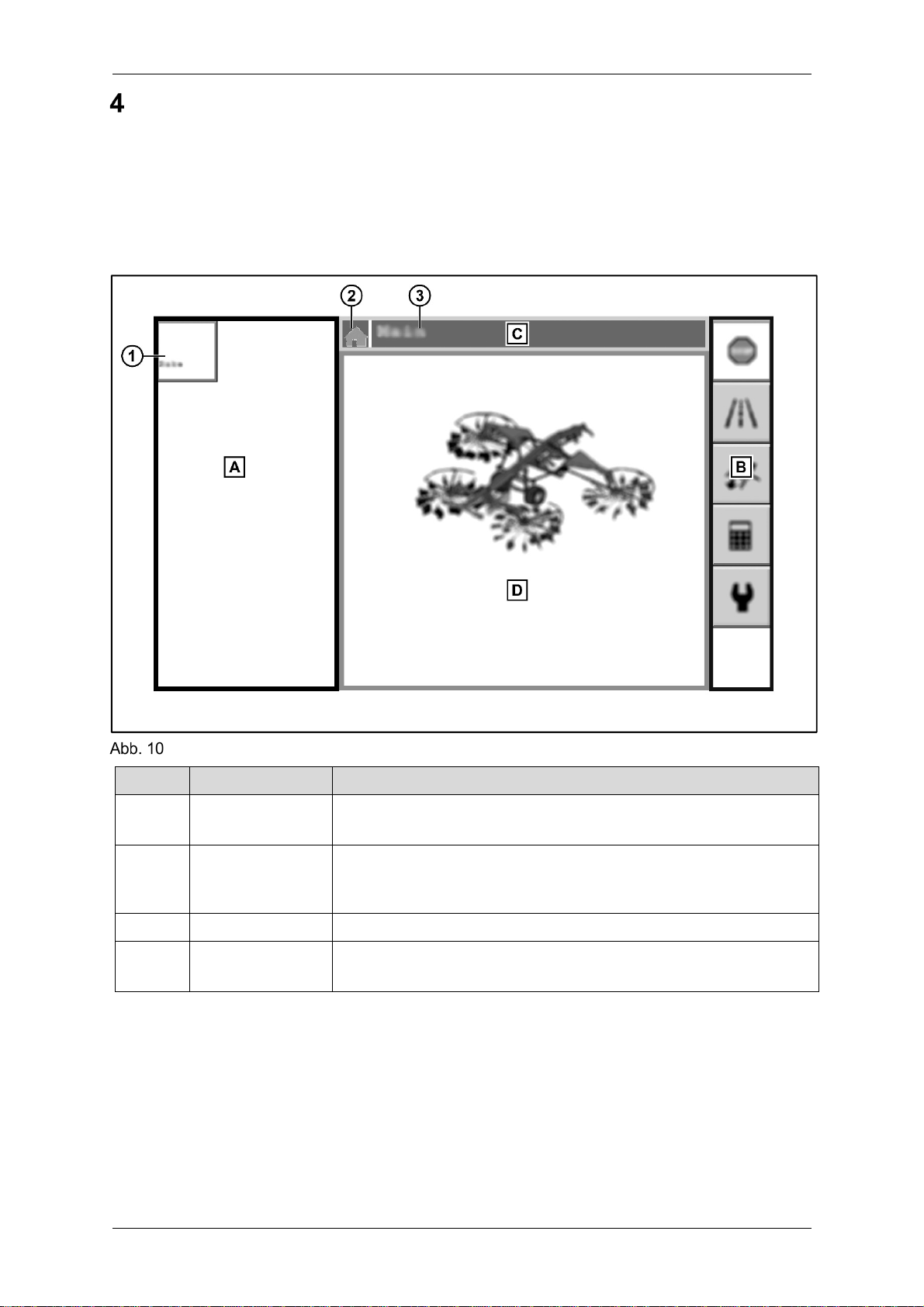

4.1Display layout 16

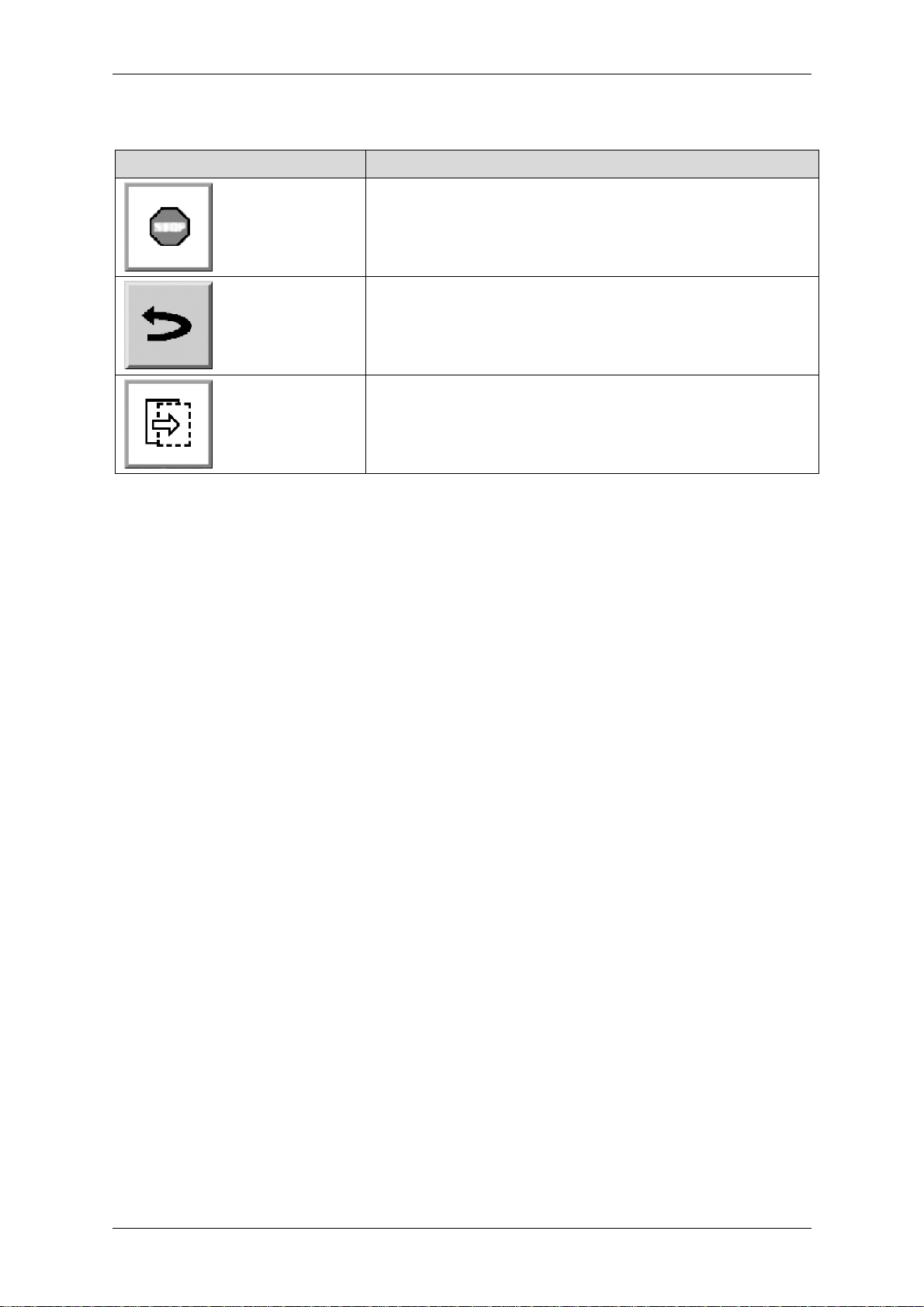

4.2General buttons 17

4.3Menus 18

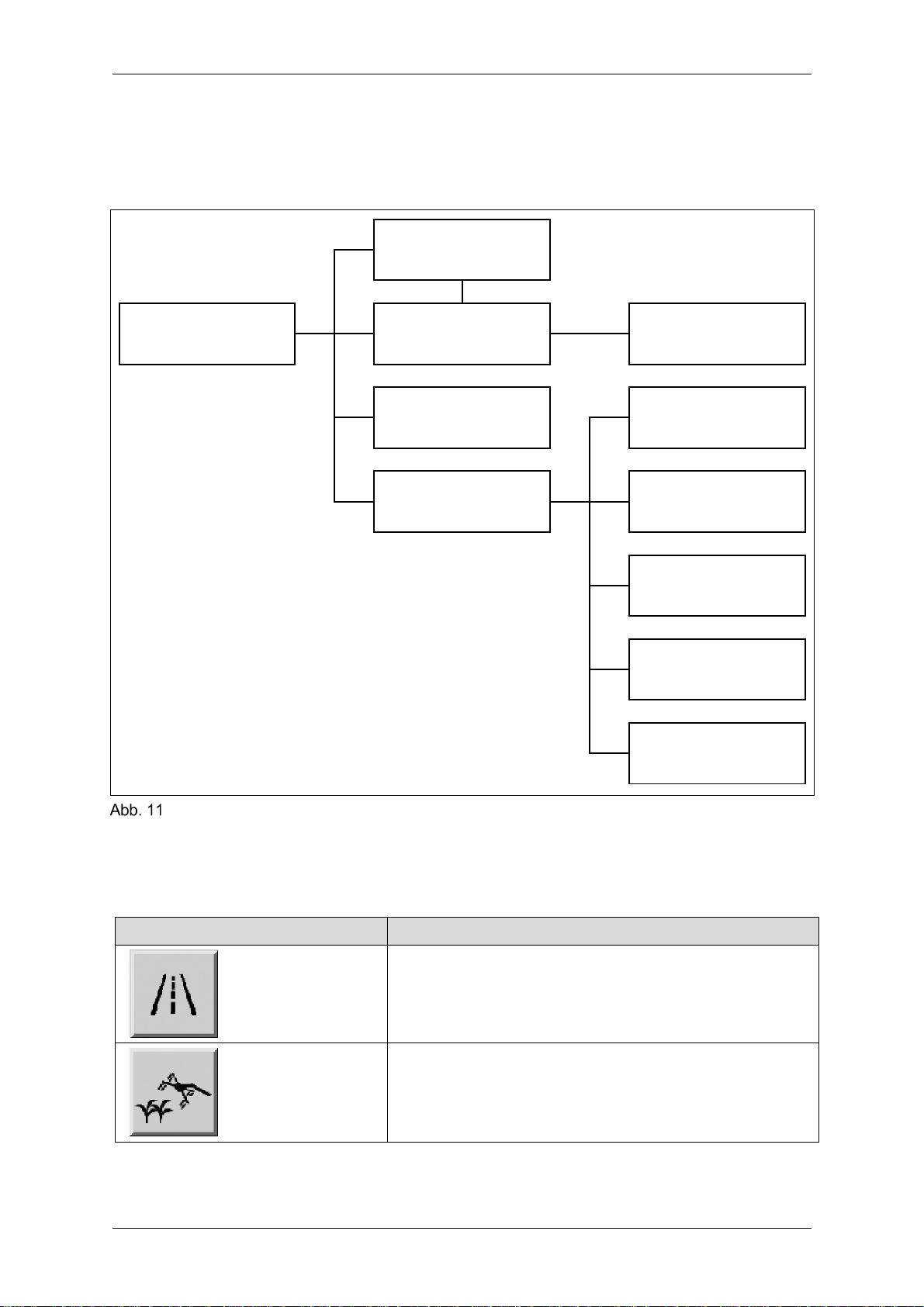

4.3.1Menu structure 18

4.3.2"Main menu" 18

4.3.3"Transport" menu 19

4.3.4"Lifting/Lowering" menu 21

4.3.5"Working Setup" menu 24

4.3.6"On-Board Computer" menu 26

4.3.7"User Setup" menu 27

4.3.8"Manual Operation" menu 28

4.3.9"Headland position" menu 30

4.3.10"Calibrations" menu 31

4.3.11"Diagnostics" menu 32

4.3.12"Factory Settings" menu 33

4.4Error messages 34

5.1Machine data 36

5.2Tires 36

5.3Noise information 37

5.4Axle loads, gross weight and minimum ballast required 38

6.1Assembling the machine 39

6.2Adjusting the transmission shaft 39

7.1Attachment to the tractor 41

7.1.1Start-up 41

7.1.2Coupling the machine 41

7.1.3Fitting the transmission shaft 42

7.1.4Connect the hydraulics 42

7.1.5Connect the lighting 43

7.1.6Connecting the ISOBUS 44

7.1.7Connect the air pressure brake 44

7.1.8Releasing the parking brake 44

7.2Road travel 44

7.3Switching the machine to working position 45

7.4Using the machine 46

7.4.1Turning at the end of the field 47

7.5Switching the machine to transport position 48

7.6Machine storage 49

7.7Settings 51

7.7.1Adjusting the swath width 51

7.7.2Set working width 51

7.7.3Adjusting working height 52

4 FORMER 12545 PRO

7.7.4Adjusting the height of the swath former 52

7.7.5Adjusting the swath formation 53

7.7.6Adjusting the lateral inclination 53

7.7.7Adjusting the longitudinal inclination 55

7.7.8Adjusting the sequential control 55

7.7.9Setting the two-rotor operation mode 56

7.7.10Setting individual rotor operation mode 56

9.1After hitting an obstacle 60

9.2Emergency operation 60

9.2.1Lifting rotors into the transport position 60

9.2.2Lowering rotors into working position 61

9.2.3Lifting rotors into the headland position 61

9.2.4Setting the working width in emergency operation 61

9.2.5Setting the swath width in emergency operation 61

9.2.6Setting the working height in emergency operation 61

10.1Maintenance intervals 62

10.2Cleaning 63

10.3Tightening torques for nuts and bolts 63

10.4Decals 63

10.5Transmission shaft maintenance 64

10.6Servicing the hydraulics 64

10.7Brake system maintenance 67

10.7.1Checking the thickness of the brake pads 67

10.7.2Tightening brake cylinders 67

10.7.3Drain the water from the compressed air reservoir 68

10.8Gearbox maintenance 68

10.8.1Checking gearbox GT-30 oil level 68

10.8.2Checking gearbox GT-40 oil level 68

10.8.3Checking transfer gearbox oil level 68

10.9Tire maintenance 69

10.9.1Changing wheels 69

10.9.2Tire pressure 69

10.10Lubrication instructions 69

11.1Storage 71

11.2Disposal 71

Introduction

FORMER 12545 PRO 5

Introduction

These operating instructions for the

FORMER 12545 PRO rotor rake contain

detailed instructions and information re-

garding safe use, maintenance, special

precautions and any special equipment that

is available.

As a result of continuous further develop-

ment of the machines, all technical data, il-

lustrations and photos in this Operator's

Manual are non-binding and we reserve the

right to make changes. No alteration ser-

vice is offered for this Operator's Manual.

Read the Operator's Manual carefully be-

fore switching on or using the machine for

the first time. The Operator's Manual helps

familiarize the user with the machine's op-

eration and provides details about function

and maintenance.

The Operator's Manual must be available

to the user at all times and must be within

reach, close to the machine.

The information regarding maintenance

and operational safety that is provided in

the Operator's Manual must be observed

and complied with.

In order to visualize it better, safety equip-

ment and covers have been removed or

opened in some of the illustrations or pho-

tos featured in this Operator's Manual.

1.1 Warranty and liability

The “General terms and conditions of sales

and delivery” of the manufacturer always

apply. These are made available to the op-

erator on the date of conclusion of the con-

tract at the latest.

1.2 Conventions

The following conventions apply to this Op-

erator's Manual.

1.2.1 Illustrations

The illustration comes first, followed by the

text. In-text references to items in the illus-

trations always refer to the previous illustra-

tion.

1.2.2 Pictograms used

Pictograms are used to highlight passages

relevant to safety or hazardous areas on

the machine.

Pictogram Explanation

Warning symbols warn

against dangers and indicate

warning notices.

Pictograms in combination

with the warning triangle indi-

cate hazardous areas on the

machine (e.g. crushing haz-

ards).

1.2.3 Text symbols

Highlight sym-

bol

Meaning

Instruction or prompt for the

user to carry out a particular

action in the specified order

Unordered list for a clearer

presentation of contents

1. Numbered list, the order of

which must be maintained

(1) Reference to an item num-

ber in an illustration

1.2.4 Abbreviations

Abbrevia-

tion

Meaning

SA Single-acting

DA Double-acting

CAT Category

1.3 Other applicable documen-

tation

When operating the FORMER 12545 PRO

rotary rake, observe all Operator's Manuals

that accompany other components of your

rotary rake.

Other applicable documentation includes:

Operator's Manual for the relevant

transmission shaft.

Introduction

6 FORMER 12545 PRO

1.4 Storage of documentation

Keep this Operator's Manual and all other

supplied documentation in the document

storage box so that they are available when

required.

1.5 Applicability of the Opera-

tor's Manual

This Operator's Manual applies exclusively

to the FORMER 12545 PRO rotary rake,

starting from the serial number specified on

the back of this manual. The serial number

of your rotary rake can be found in the ve-

hicle identification number (VIN) on the

sign plate.

The FORMER 12545 PRO DB rotary rake

is also referred to as "the machine" in the

following sections.

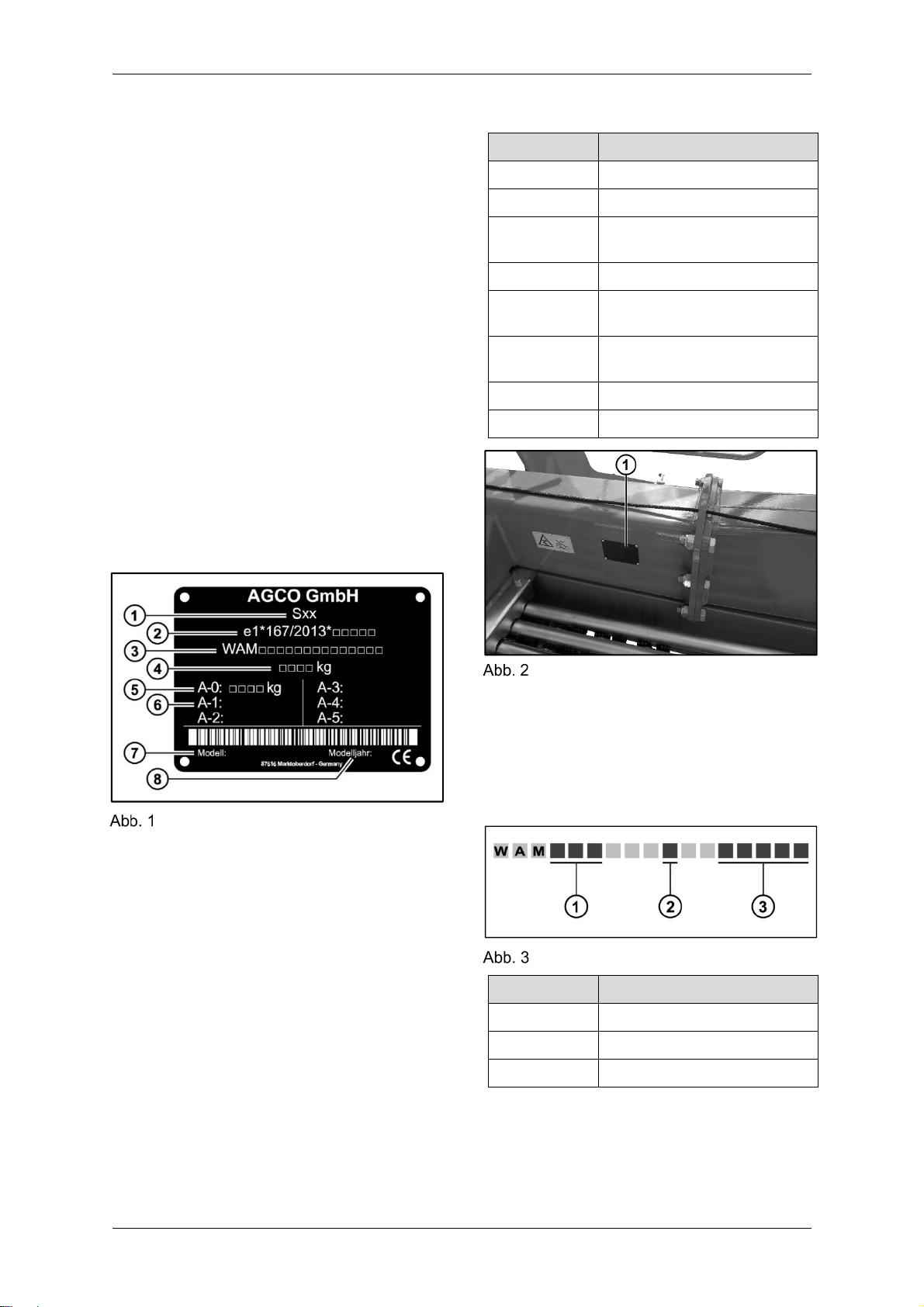

1.6 Sign plate and serial num-

ber

Sign plate

The sign plate includes the following infor-

mation:

Number Information

1 Vehicle class

2 EU type approval number

3 Vehicle identification number

(VIN)

4 Permissible overall weight

5 A-0: Permissible drawbar

load

6 A-1: Permissible axle load,

1st axle

7 Model

8 Model year

Sign plate on the frame

The sign plate (1) is riveted to the frame. It

displays the vehicle identification number

(VIN). The VIN is also stamped on the

frame.

The VIN contains the serial number of the

machine.

FIN/VIN

Number Information

1 Alphabetic code

2 Year of manufacture, coded

3 Consecutive number

Introduction

FORMER 12545 PRO 7

1.7 EU Declaration of Conformity

Manufacturer

AGCO GmbH

Johann Georg Fendt Straße 4

87616 Marktoberdorf

Germany

Product

Designation: Rotary rake

Type: RE

Model: FORMER 12545 PRO

The machine meets the relevant provisions of the following directives:

Machinery Directive 2006/42/EC

EMC Directive 2004/108/EC

The following harmonized standards have been applied:

DIN EN ISO 12100:2011

DIN EN ISO 4254-1:2011

DIN EN ISO 4254-10:2010

The following person is authorized to compile the technical documentation.

Lead Homologation Green Harvesting

Fellastraße 1-3

90537 Feucht

Germany

Marktoberdorf, 2019-07-01 Dr. H. Reiter (Managing Director)

Safety

8 FORMER 12545 PRO

Safety

2.1 Intended use

The rotary rake is used to rake together cut

stalks lying on the ground into a centrally

deposited swath. To do so, the machine

must be in the working position. This ma-

chine has been constructed exclusively for

normal use in agricultural or similar tasks.

Any other type of use is considered unau-

thorized. The manufacturer accepts no re-

sponsibility for any damage caused by im-

proper use. The user alone is responsible

for this.

"Proper use" includes:

Observing all of the information on how

to use the machine in the Operator's

Manual

Taking all warnings into account

Carrying out all inspections and mainte-

nance work as instructed when they are

due

2.2 Reasonably foreseeable

misuse

Examples of reasonably foreseeable mis-

use that may consequently pose a hazard

for the user, third parties or for the machine

during all modes of operation are:

Not using the machine in accordance

with the proper use

Operating the machine without observ-

ing the operational parameters de-

scribed in the machine data table

Changing the machine, along with at-

tachments and modifications, without

previously consulting the manufacturer

Not using the machine as instructed in

the Operator's Manual, with regard to

safety instructions, installation, opera-

tion and maintenance and repair

Bypassing or decommissioning the ma-

chine's protective and safety equipment

Using an obviously damaged or faulty

machine

Repairing, cleaning or servicing the ma-

chine without switching it off

2.3 User qualifications

This Operator's Manual is intended for

farmers who operate, service and hitch the

machine to the tractor themselves, and for

other trained persons who use the ma-

chine. According to health and safety law, it

is the responsibility of the owner to provide

any other users with the necessary infor-

mation.

Necessary information is obtained from:

Instruction and training in assigned

tasks

Providing information about potential

risks associated with improper handling

Instructions about:

- Necessary protective equipment

- Protective measures

- Relevant regulations

- Accident prevention regulations

- Operating conditions

It is assumed that the user is familiar with

basic mechanics and hydraulics.

Any person using the machine (the user)

must follow the Operator's Manual and ob-

serve the respective safety instructions for

every task/activity.

As a basic prerequisite, the user must have

valid authorization for transporting the ma-

chine on the road using a tractor or appro-

priate towing vehicle in order to be allowed

to transport such equipment on the roads.

2.4 Warning notices

2.4.1 Warning notices in the Opera-

tor's Manual

In these documents, each warning has a

key word that indicates the extent of the

risk involved.

The first few lines below the key word de-

scribe the nature and source of the po-

tential risks.

Safety

FORMER 12545 PRO 9

The following section indicates the conse-

quences that may occur if no measures for

preventing the risk(s) are taken.

The final section outlines risk-prevention

measures.

The following key words are used.

DANGER

Situation posing an immediate hazard that

could lead to serious injury or death if the

respective warning is ignored.

WARNING

Potentially hazardous situation leading to

serious injury or death if the respective

warning is ignored.

CAUTION

Potentially hazardous situation leading to

minor or slight injury if the respective warn-

ing is ignored.

ATTENTION

Potentially hazardous situation leading to

material damage if the warning is ignored.

2.4.2 Warning notices on the ma-

chine

Warning notices on the machine are decals

that indicate residual risks. Residual risks

are hazards or hazardous areas that can-

not be sufficiently prevented or secured

through technical preventive measures

alone.

Warning notices attached to the ma-

chine must be observed.

Prior to each use, check that the decals

are in good condition.

Replace any illegible or damaged de-

cals.

Replace any missing decals.

Warning notices on the machine

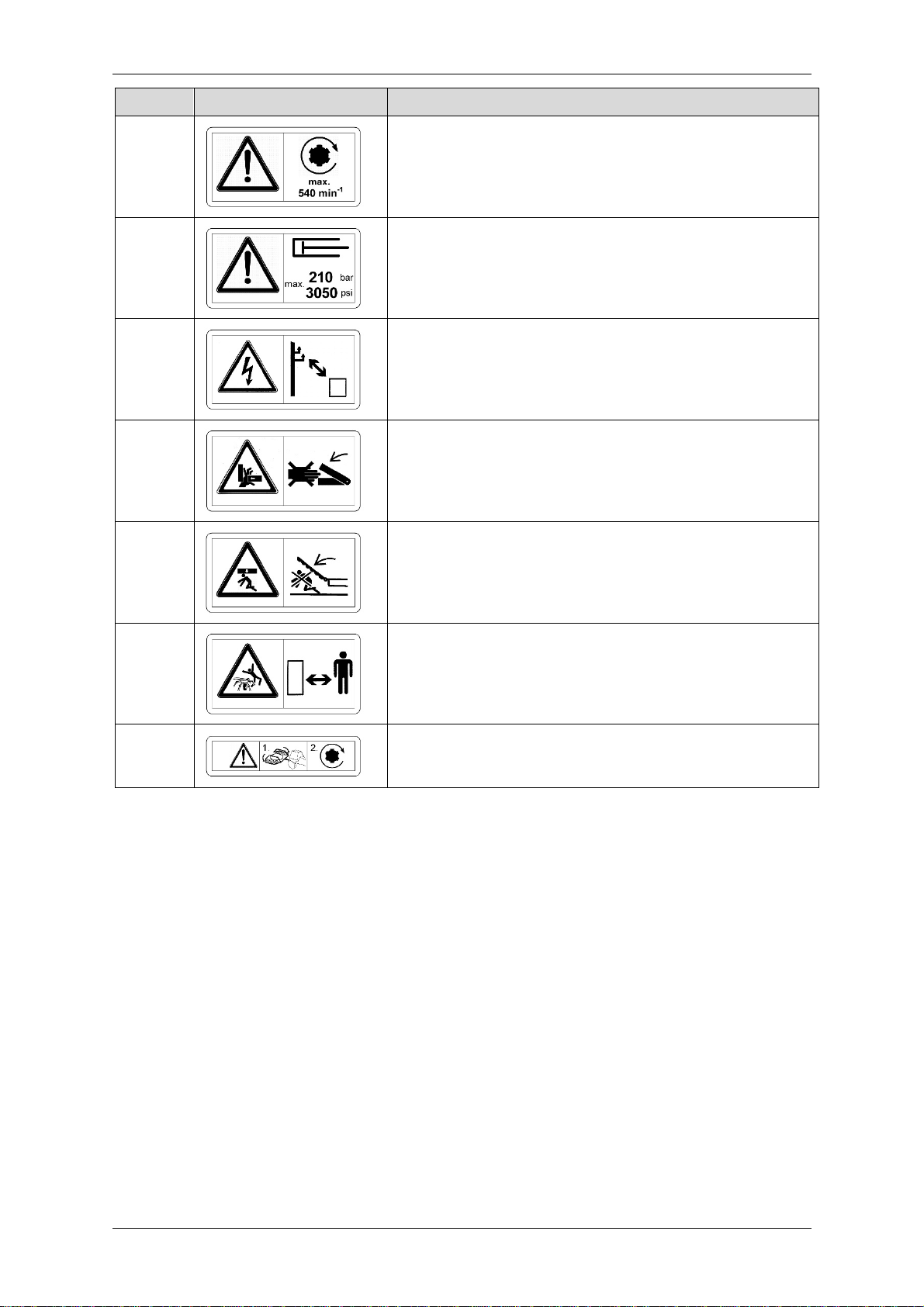

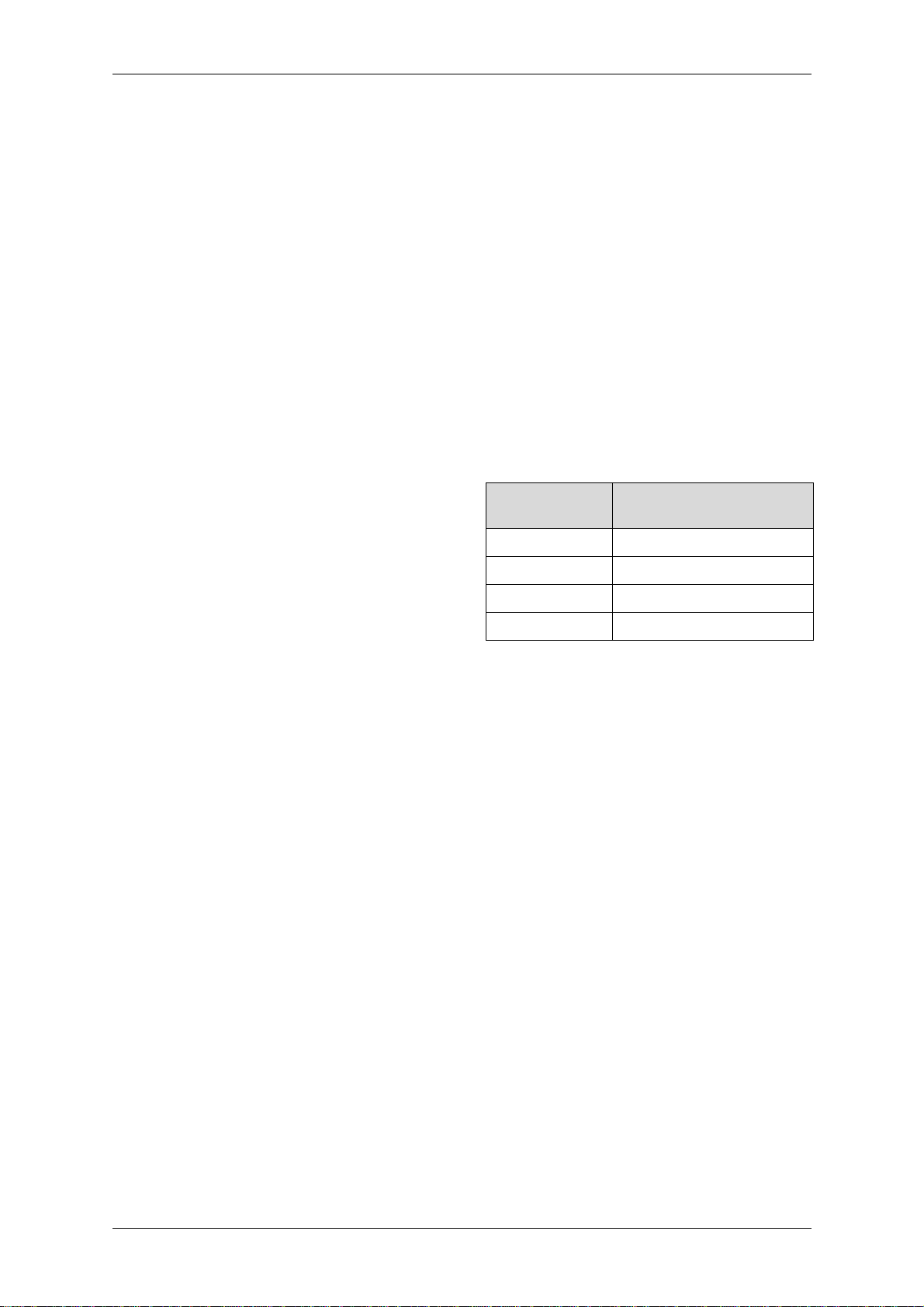

Number Warning Explanation

1

Before using the machine for the first time, read the Op-

erator's Manual and safety instructions. Always observe

the Operator's Manual and safety instructions while us-

ing the equipment.

Safety

10 FORMER 12545 PRO

Number Warning Explanation

2

Do not exceed the maximum permissible drive speed

of 540 rpm.

3

Do not exceed the maximum permissible hydraulic

pressure of 210 bar/3050 psi.

4

When raising the machine and when it is in the transport

position, maintain a sufficient distance from high-

voltage power lines.

5

Never reach into an area where there is a risk of

crushing while parts may still be moving in that area.

6

Keep out of the swiveling range.

7

Maintain a safe distance from the rotating rotors.

8

Before switching on the PTO shaft, move the arc-

shaped guard to the safety position.

2.5 Safety instructions

The safety instructions are always applica-

ble for the safe use of the machine and for

maintaining the machine in a safe condi-

tion. The Operator's Manual and, in particu-

lar, all of the safety instructions contained

therein, must therefore be read through be-

fore using the machine for the first time and

kept in mind during use.

This helps to ensure that the machine is

used safely, and protects both the user and

people in the vicinity of the machine.

When assembling, using, troubleshoot-

ing and servicing the machine, always

observe the general safety instructions

and the warnings and symbols which

precede each operation.

Observe all warnings and symbols at-

tached to the machine.

Observe all other safety regulations that

are relevant to the machine, both gen-

eral and region-specific.

2.5.1 Operating and maintenance

personnel

Users must be sufficiently physically and

mentally fit to be able to react quickly and

cautiously.

Persons who are unwell or injured or are

under the influence of medication, drugs,

alcohol or exhaustion are prohibited from

operating the machine.

Safety

FORMER 12545 PRO 11

2.5.2 Protective work wear

Loose clothing, jewelry or long hair can be-

come entangled in moving parts.

Wear close-fitting clothing.

Remove any jewelry or other objects

that could become caught in moving

parts.

Tie up long hair and/or wear a head

covering.

2.5.3 Personal protective equipment

Wear the personal protective equipment

specified in the instructions. This includes:

Safety gloves

Protective goggles

2.5.4 Preparing the machine for use

To avoid putting the user and other per-

sons in danger, the machine must be pre-

pared before each use.

Before starting work, ensure that you

are familiar with all safety equipment

and operating elements and their func-

tion.

Inspect the lighting equipment to en-

sure that it is functioning properly.

Test the protective equipment and

move it to the respective specified oper-

ating position (transport position/work-

ing position).

Inspect the hydraulic hoses before each

use. Replace any lines that show signs

of damage and/or ageing.

2.5.5 Coupling/uncoupling the ma-

chine to/from the tractor

Take special care when coupling and un-

coupling the machine.

Make sure that there are no persons in

the hazard area when maneuvering. In-

struct any persons present to leave the

hazard area.

When operating the tractor hydraulics,

make sure that there are no persons

within the movement range of the lower

links and top link.

After coupling the machine, fit the lock-

ing devices (hairpins or cotter pins) cor-

rectly.

2.5.6 Machine operation

When the machine is in operation, the user

must be able to reach in quickly at any

time. There are moving working tools on

the machine, which could cause injury to

persons or even death.

Only ever operate the machine from the

tractor seat.

Riding on the machine is prohibited.

Check the surrounding area before

starting up.

Ensure you have sufficient visibility.

Make sure that no-one is present in the

pivoting or working area of the ma-

chine.

Instruct persons to leave the hazardous

area.

If you leave the tractor seat in order to

carry out adjustments, switch off the

machine and the tractor engine and re-

move the ignition key.

2.5.7 Driving on public roads and

lanes

For driving on public roads and lanes, spe-

cial national regulations apply. Other road

users must also not be put in danger.

Before driving on roads, check the con-

dition of all signaling and lighting equip-

ment and ensure that it is functioning

correctly.

Clean dirty signaling and lighting equip-

ment before driving off.

To maintain steerability, the attached

machine must never take too much

load off the front wheels of the tractor.

Attach load weights to the front of the

tractor if required.

Keep permissible vehicle dimensions in

mind.

Observe the tractor's permissible axle

loads and gross weights.

Safety

12 FORMER 12545 PRO

The technically permissible maximum

speed is 40 km/h. Observe national

speed limit regulations.

On public roads and lanes, the machine

must be driven in transport position

only.

Riding on the machine is prohibited.

2.5.8 Maintenance work

It is necessary to perform maintenance

work on the machine to guarantee that it is

in a safe operating condition and to avoid

any unnecessary repairs. Performing work

incorrectly can lead to injuries.

Before carrying out maintenance work,

switch off the tractor engine and re-

move the ignition key.

Only perform maintenance work as de-

scribed in these instructions.

Any work that is not specified in these

instructions must only be carried out by

specialist personnel in a specialist work-

shop.

Repairs to tires and wheels must only

be carried out by specialist personnel

using the appropriate fitting tools.

2.5.9 Working with hydraulics

Incorrect connections can lead to reversed

operation (e.g. raising/lowering).

Observe the markings on the hydraulic

hoses to avoid mixing up the hoses.

Escaping high-pressure fluids can pene-

trate the skin and cause serious injuries

and/or infections.

Any work on hydraulic systems must

only be carried out by authorized quali-

fied personnel.

Before starting work, release the pres-

sure in the hydraulic system.

Inspect the hydraulic lines before each

use and replace any lines that show

signs of damage or ageing.

Check for leaks using a piece of card-

board or wood. When doing so, do not

direct the oil jet towards your body.

In the event of injuries, seek medical at-

tention immediately.

2.5.10 Work in the vicinity of high-

voltage power lines

Particular care must be taken when work-

ing under or close to high-voltage power

lines. In particular, this applies when folding

up the machine and traveling with the ma-

chine in transport position.

Before carrying out planned work close

to high-voltage power lines, obtain the

necessary information about the rated

voltage and the minimum overhead line

clearance from the relevant operator.

The safety distances must not fall short

of the values in the table under any cir-

cumstances.

Rated voltage

[KV]

Safety distance from

overhead lines [m]

≤1 1

>1-110 3

>110-220 4

>220-380 5

2.5.11 Unauthorized modifications or

alterations

If unauthorized modifications or alterations

are carried out, the machine can present a

danger.

Do not carry out any modifications or al-

terations to the machine that have not

been discussed with and authorized by

the manufacturer.

2.5.12 What to do in an emergency

In the event of a dangerous situation, fast

action is required to protect the user or an-

yone else from being injured.

Switch off the tractor immediately.

Contact the emergency services if nec-

essary.

2.5.13 Fire prevention

Regular maintenance and cleaning of the

machine will reduce the risk of fire.

Safety

FORMER 12545 PRO 13

Remove harvesting residue from the

machine.

Listen for unusual noises every time

you operate the machine.

Machine description

14 FORMER 12545 PRO

Machine description

The rotary rake is used to rake together cut

stalks lying on the ground into a centrally

deposited swath.

3.1 Product features

Cardanic suspension of the rotors

Central tube frame with central chassis

axle

Drawbar swivel head

Removable tine carriers

Folding arc-shaped guards

Automatically operated swath former

Drive train with overload protection on

each rotor

Air pressure brake

ISOBUS control system

3.2 Machine positions

3.2.1 Transport position

In the transport position, all rotors are fully

raised. The support leg is swung up.

3.2.2 Working position

In the working position, the rotors are low-

ered. The support leg is swung up.

3.2.3 Headland position

In the headland position, the rotors are

lifted to a height set by sensors. The sup-

port leg is swung up.

3.2.4 Parking position

The rotors are fully raised in the parking

position. The support leg is swiveled down-

ward.

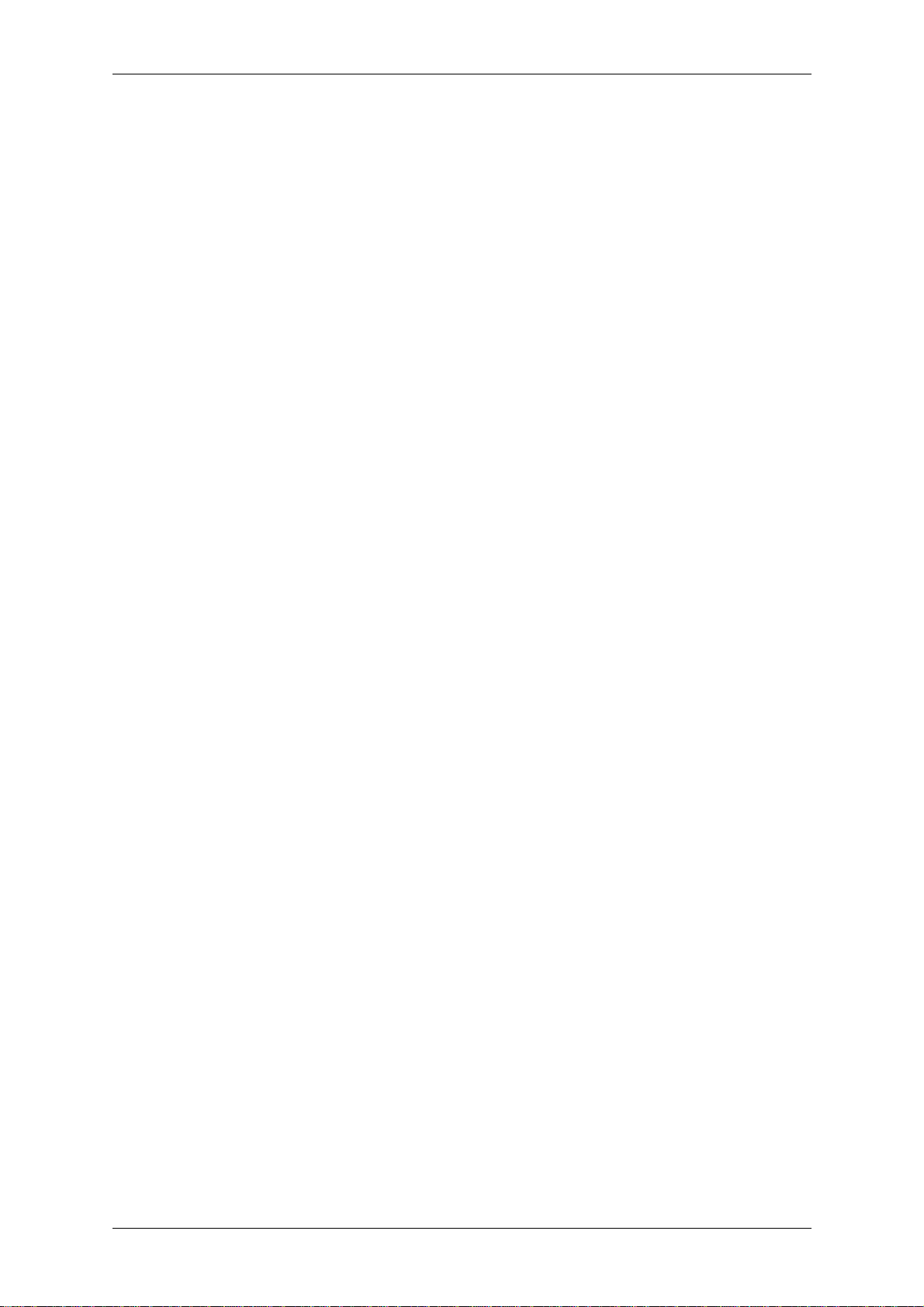

3.3 Notices on the machine

Operating speed

This decal shows the optimal range for the

drive speed during raking.

Lifting point

The decal indicates an attachment point for

a crane.

Hoist attachment point

This decal indicates the hoist attachment

point.

Tire pressure

This decal shows the maximum permissible

tire pressure.

Machine description

FORMER 12545 PRO 15

3.4 Machine components

Machine components

Position Designation

1 Towing bracket

2 Support leg

3 Swivel arm

4 Twin leading wheel

5 Gyro

6 Trailing wheel

7 Safety device

8 Tine carrier

9 Transport chassis

10 Tandem wheels

11 Warning sign with lighting

12 Swath former

13 Parking brake

14 Main frame

A Direction of travel

B Right

C Left

ISOBUS control system

16 FORMER 12545 PRO

ISOBUS control system

4.1 Display layout

A schematic diagram of the display is described below. The display on the actual ISOBUS

terminal may differ from the diagram.

Four sections are shown on the display. The software for each ISOBUS component contains

one or more menus.

Schematic diagram

Section Designation Description

A Component menu - All ISOBUS components are displayed

- There is a button for every ISOBUS component (1)

B Button panel - Displays buttons for selecting different menus or implementing

actions

- The buttons displayed depend on the menu

C Header - Shows the symbol for (2) and tile of (3) the current menu

D Function section - Section for displays, images and specific settings

- Contents depend on which menu is open

ISOBUS control system

FORMER 12545 PRO 17

4.2 General buttons

There are three buttons with general functions.

Button Function

Stop - The action being implemented is interrupted and the "Man-

ual Operation" menu opens

Back - Goes back to the previous menu

- Stops an action being implemented

Next - Changes the buttons that are visible in the panel

- Only available when there are more buttons in the menu

than can be displayed at one time

ISOBUS control system

18 FORMER 12545 PRO

4.3 Menus

4.3.1 Menu structure

The software has various menus for operating the machine. Every menu has a specific icon

and a unique title in the header.

Transport

Main menu Lifting/Lowering Working Setup

On-Board Computer Manual Operation

User Setup Headland Position

Calibrations

Diagnostics

Factory Settings

Menu structure

4.3.2 "Main menu"

The "Main menu" is displayed when the software is started. The model of the machine, the

manufacturer's logo and a version number are displayed in the functions section.

Button Function

Transport - The "Transport" menu opens.

Lifting/Lowering - The "Lifting/Lowering" menu opens

- Hidden when the machine is in the transport position

Table of contents

Other FENDT Farm Equipment manuals