- 4 -

EN

1500_GB-Inhalt_2611

TABLE OF CONTENTS

Table of contents

TABLE OF CONTENTS

CE sign ...................................................................... 5

Meaning of warning signs.......................................... 5

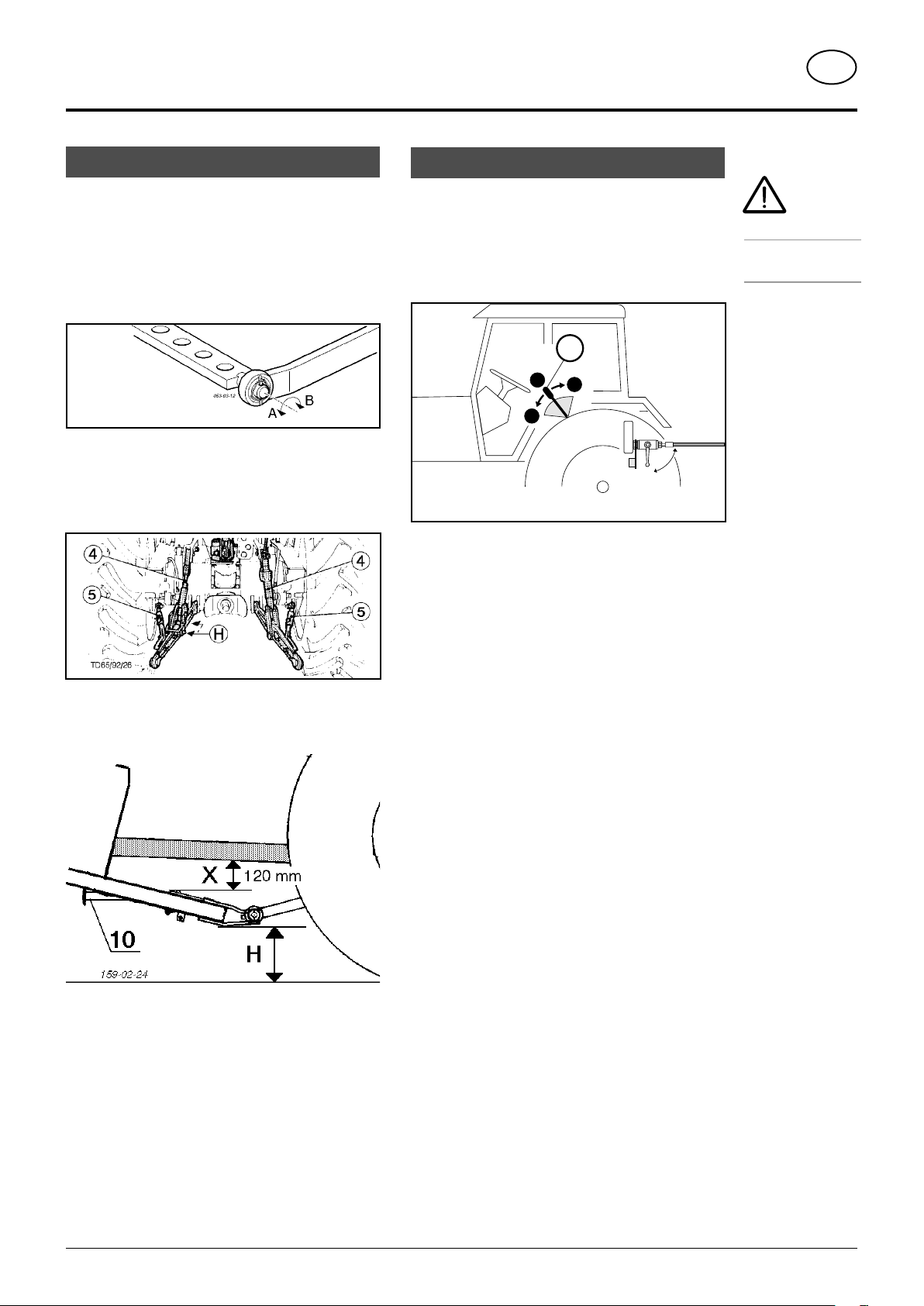

ATTACHING TO TRACTOR

Initial attaching to tractor............................................ 6

Hydraulic connection ................................................. 6

Preparations for initial use ......................................... 7

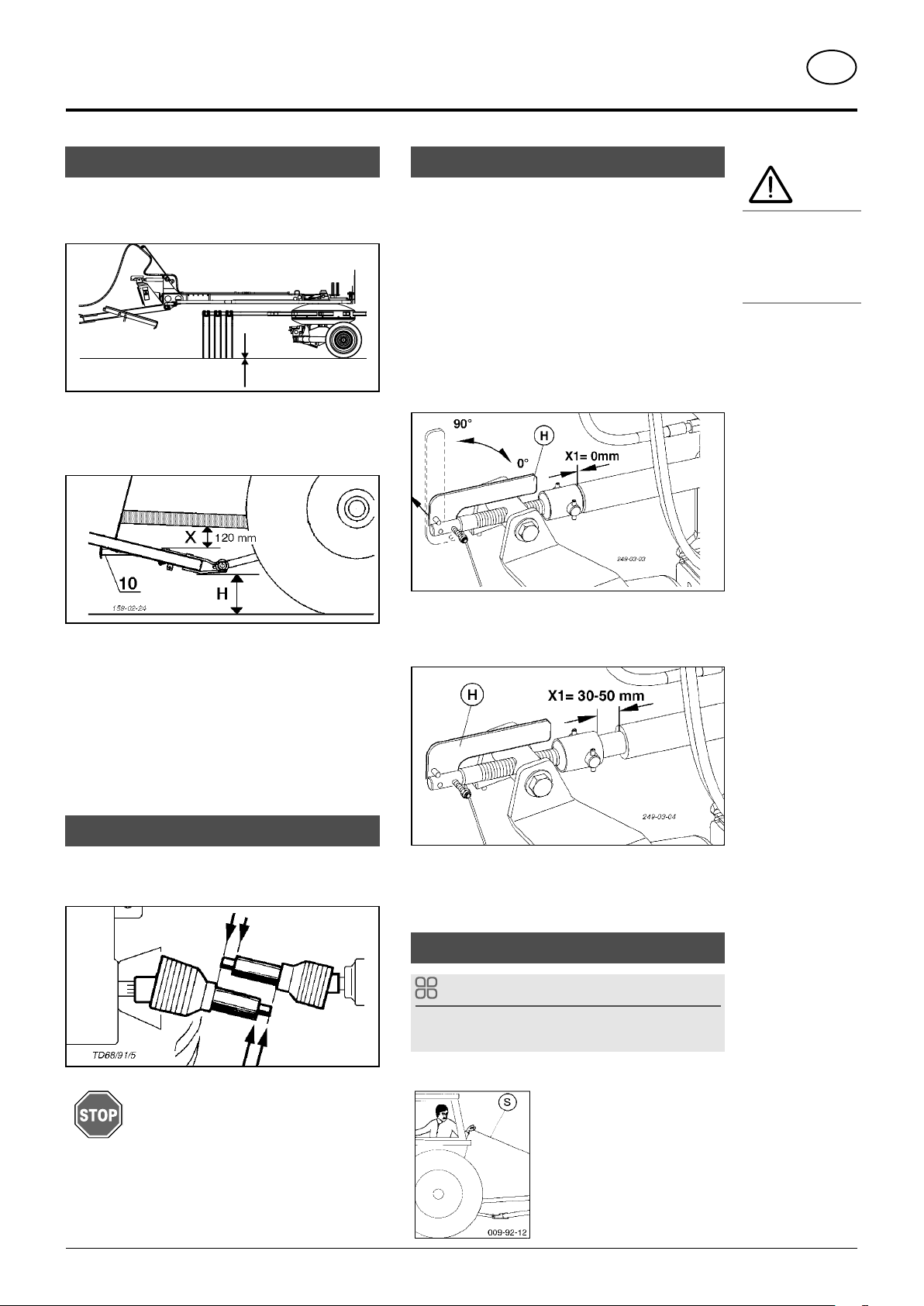

PTO shaft guarding.................................................... 7

Setting the threaded spindle ...................................... 7

Towing rope (option) .................................................. 7

LOWERING THE MACHINE

Lowering .................................................................... 8

TRANSPORT AND WORKING POSITION

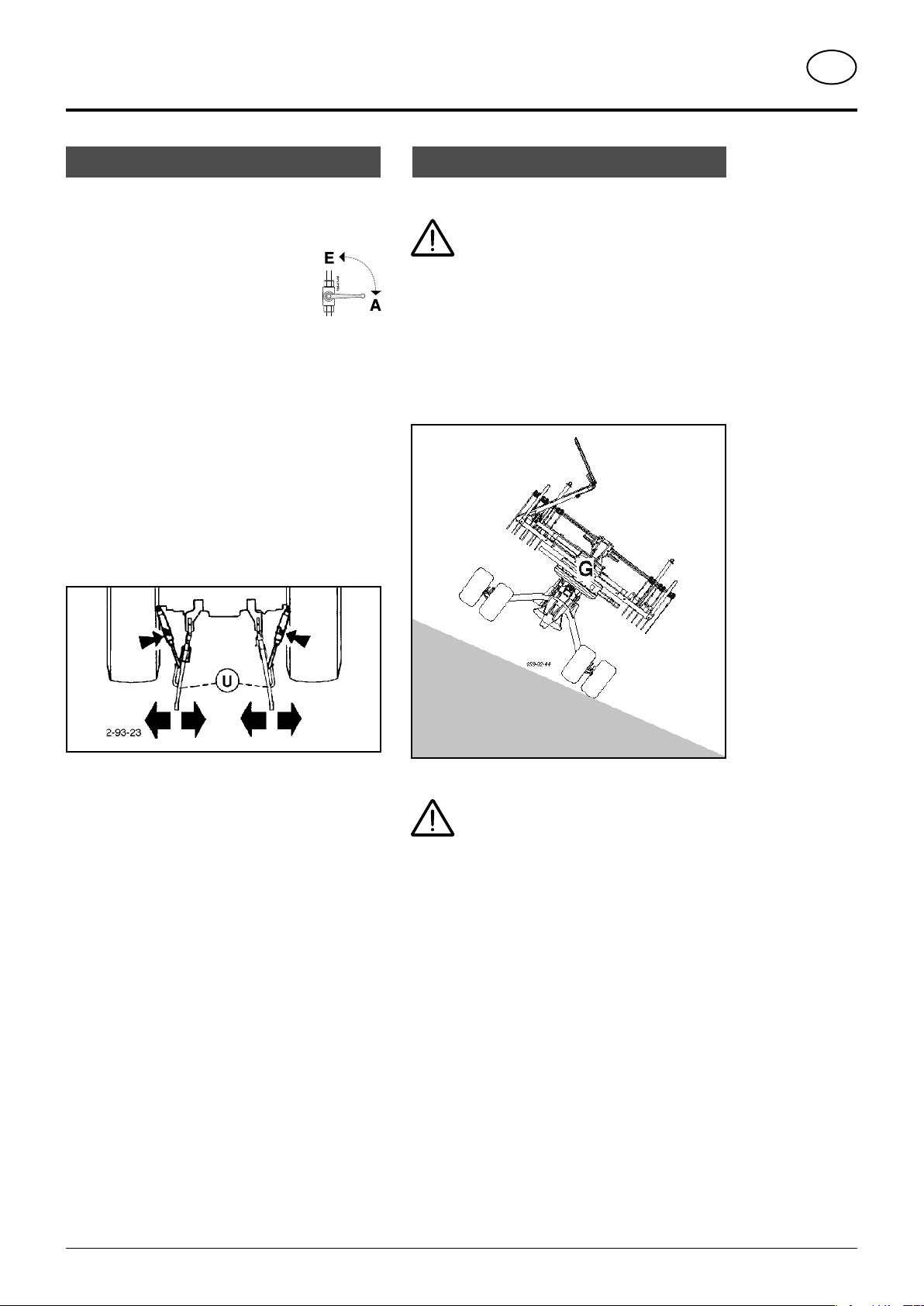

Driving on public roads .............................................. 9

Take care when turning on slopes! ............................ 9

Transport position .................................................... 10

Working position ...................................................... 10

OPERATION

Preparations for operation .......................................11

Important before starting work..................................11

p.t.o. speed...............................................................11

Hydraulic servo-valve (ST.........................................11

General guidelines for working with the

implement. ............................................................... 12

Setting the cam track............................................... 12

Hydraulic swath apron (optional) ............................. 13

Safety advice ............................................................14

General maintenance information.............................14

Cleaning of machine parts........................................14

MAINTENANCE

Parking in the open...................................................14

Winter storage...........................................................14

Cardans ....................................................................14

Hydraulic unit............................................................14

Lubrication points..................................................... 15

PTO shaft guarding ................................................. 15

Lubrication chart ...................................................... 15

Tine arms................................................................. 16

Rotor unit ..................................................................17

Spring tines...............................................................17

Lubrication chart ...................................................... 18

TECHNICAL DATA

Position of Vehicle Identification Plate ..................... 20

Defined use of the Rotary Swather.......................... 20

SUPPLEMENT

Lubricants ................................................................ 27