LH 1200S OPERATORS MANUAL

LH AGRO 3

Contents

INTRODUCTION .................................................................................................................4

GENERAL USE ...................................................................................................................5

FERTILISER DISTRIBUTOR ..................................................................................5

SEED DRILL ...........................................................................................................6

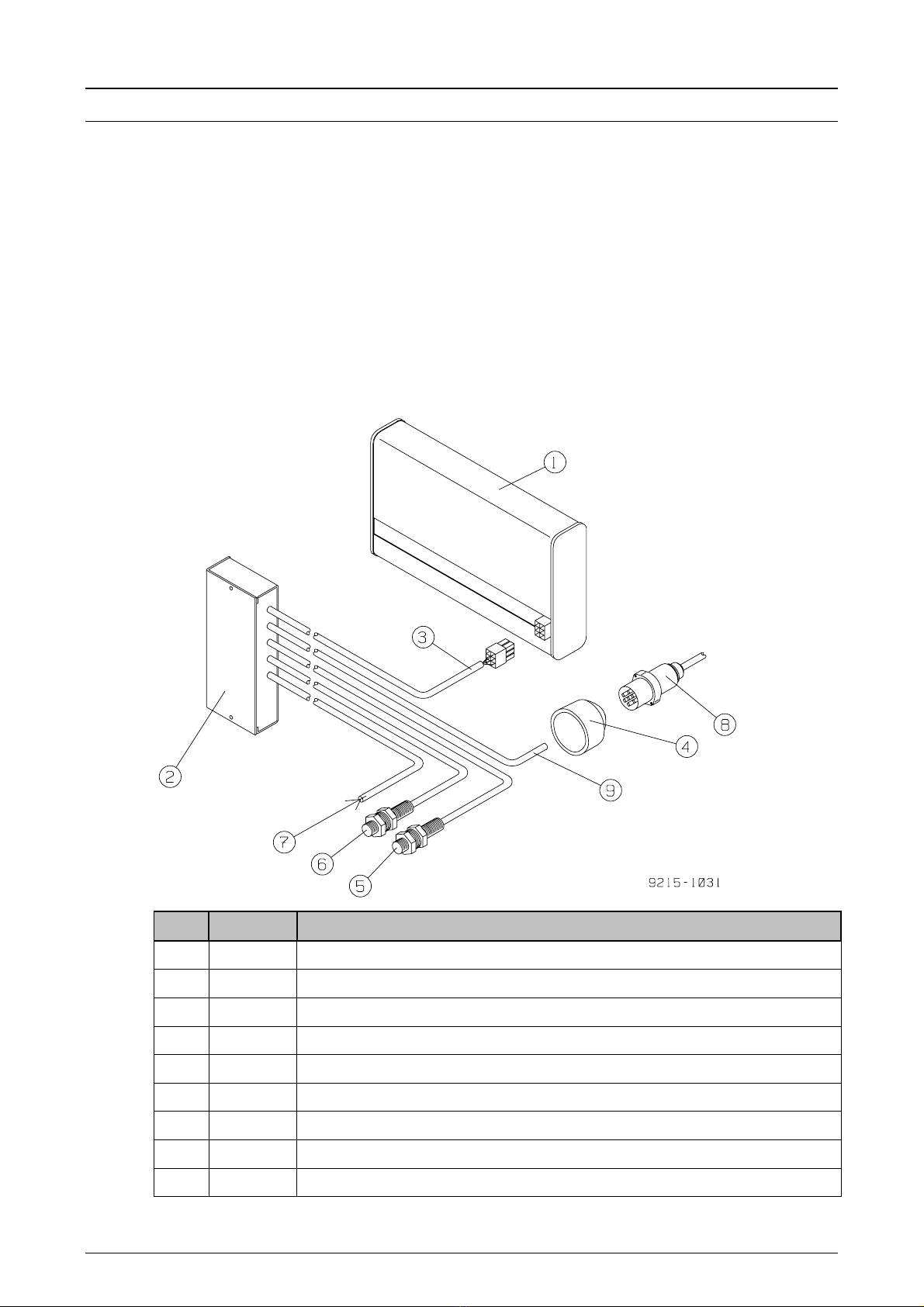

SYSTEM DESCRIPTION.....................................................................................................7

918-123 LH 1200S FITTING KIT WITHOUT SWITCHES .......................................7

916-123 LH 1200S FITTING KIT WITH SWITCHES...............................................8

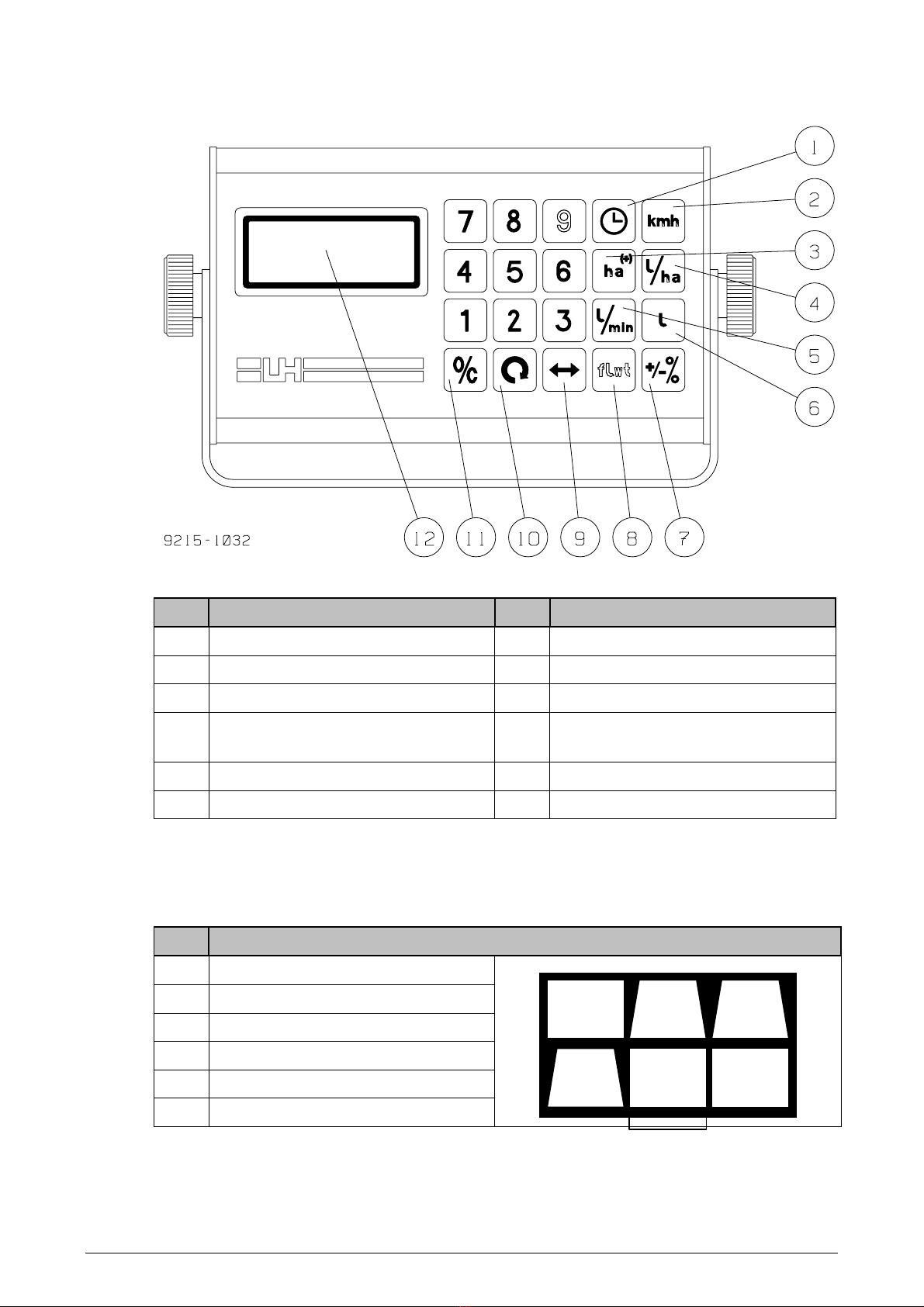

THE MONITOR ...........................................................................................................9

PLUG CONNECTIONS ...............................................................................................9

PRIMARY FUNCTIONS.....................................................................................................10

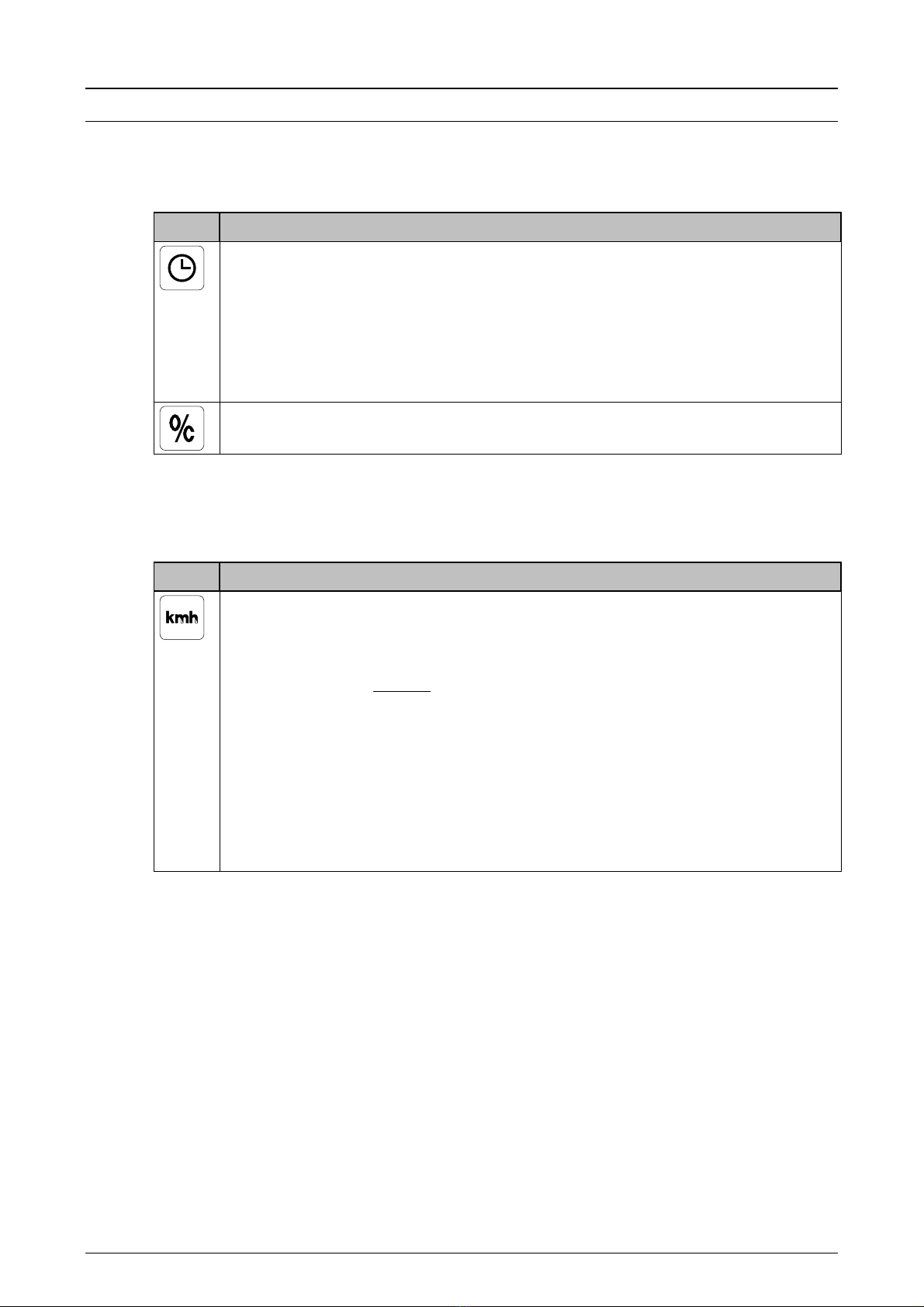

WORK TIME..............................................................................................................10

FORWARD SPEED...................................................................................................10

AREA COUNTERS ...................................................................................................11

APPLICATION RATE FOR SPRAY CHEMICALS.....................................................12

BOOM SECTION COMPENSATION ........................................................................12

SPRAY CHEMICAL CONSUMPTION PER MINUTE................................................13

SPRAY CHEMICAL CONSUMPTION.......................................................................13

SECONDARY FUNCTIONS, FERTILISER DISTRIBUTOR ..............................................14

RPM FOR DISC SPREADERS .................................................................................14

FERTILISER DISTRIBUTOR WITH FEED ROLLER (PNEUMATIC) ........................14

SECONDARY FUNCTIONS, SEED DRILL .......................................................................15

SOW AXLE RPM.......................................................................................................15

SEED RATE MONITORING......................................................................................15

SECONDARY FUNCTIONS; SLURRY SPREADER .........................................................16

APPLICATION RATE MONITORING........................................................................16

SECONDARY FUNCTIONS, BALER.................................................................................17

UNIT COUNTER .......................................................................................................17

SECONDARY FUNCTIONS, DISTANCE MEASURING....................................................17

ENCODING .......................................................................................................................18

FORWARD SPEED CALIBRATION (WHEEL CIRCUMFERENCE) .........................18

AUTOMATIC SPEED SENSOR CALIBRATION...................................................18

MANUAL SPEED CALIBRATION .........................................................................19

WORKING WIDTH AND BOOM SECTIONS ............................................................19

1. ENCODING THE WORKING WIDTH ...............................................................19

2. ENCODING BOOM SECTIONS WIDTHS.........................................................20

QUANTITY CORRECTION...................................................................................20

FLOWMETER CALIBRATION (FLOW FIGURE) ......................................................22

VOLUME MONITORING CALIBRATION FOR SEED AND FERTILISER.................23

SYSTEM TEST..................................................................................................................25

ERROR WARNING............................................................................................................25

TRAILER PLUG CONNECTIONS .....................................................................................26

SPRAYER .................................................................................................................26

FERTILISER DISTRIBUTOR/SEED DRILL...............................................................26

TECHNICAL DATA............................................................................................................27