4ENGLISH | Set-Up Instructions

Set-up Instructions

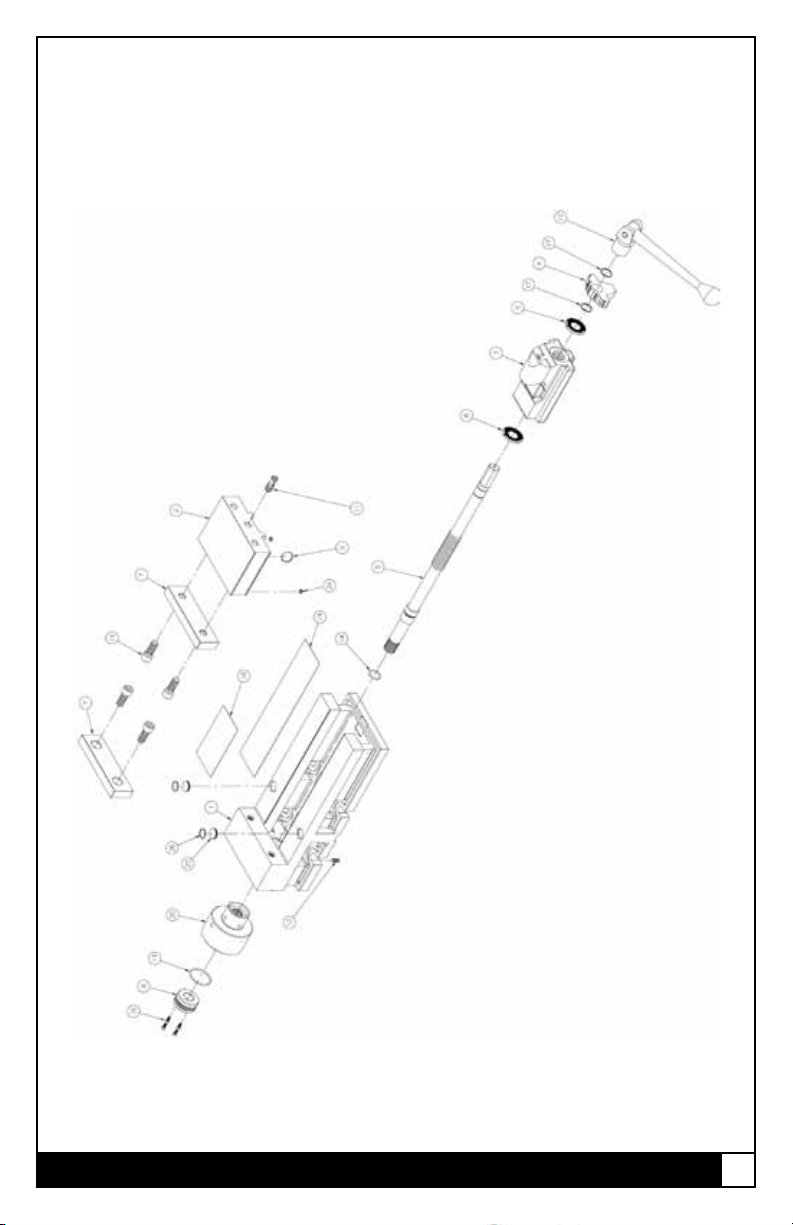

Now that you have your new Kurt 3600-Series vise, it’s time to set-

up and begin using it. You will see that your new vise comes with a

Kurt swivel handle, two chip guards (short & long) and an instruction

manual along with the O-ring installation guide supplied in the

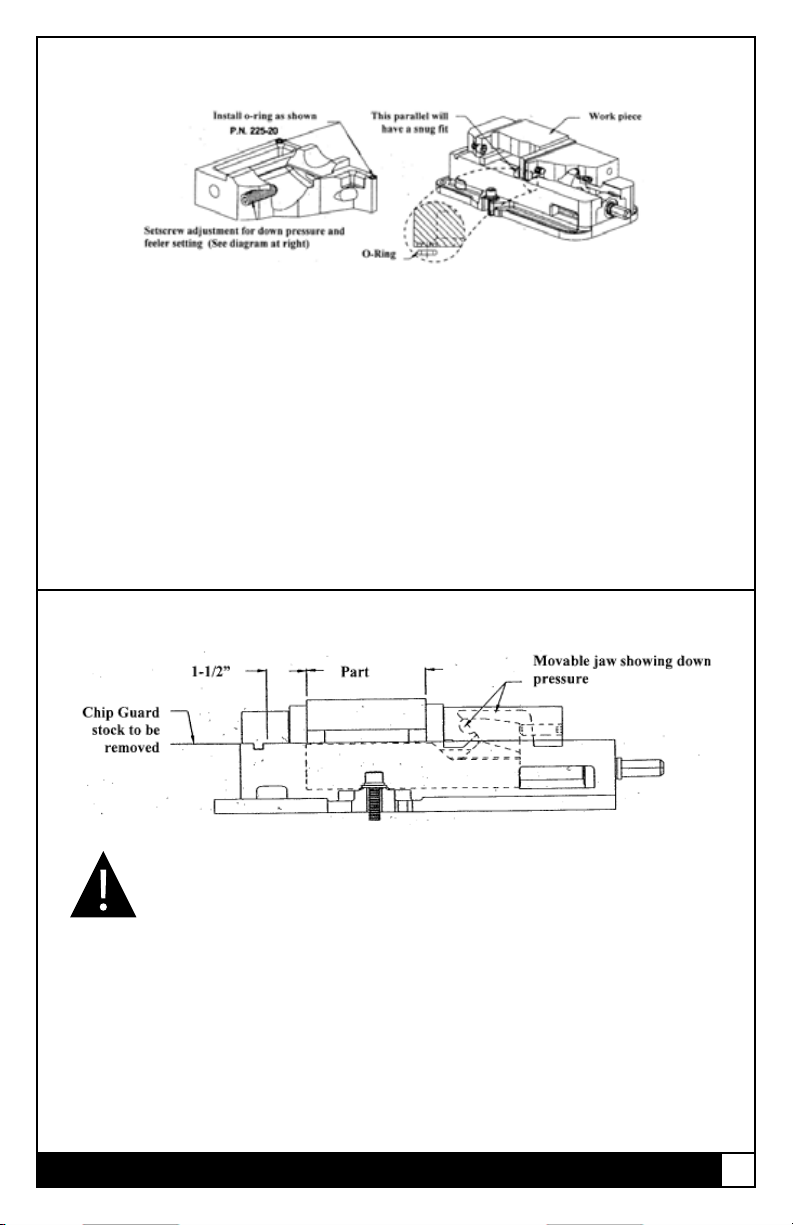

shipping carton. The chip guard rests between the ways of the vise and

can be trimmed to size to help keep the chips out of the screw. The

handle is specically designed to provide maximum torque to your

vise. Your vise should be mounted to a clean at surface. The surface

and the vise must be free of any chips, dirt or debris of any kind. The

mounting surface can be honed if necessary. Clean the bottom of the

vise with solvent or other cleaner if needed. Air activated vises require

shop air power. Air lter/lubricator required.

To minimize vise bed deection, clamp your Kurt vise to your machine

table, pallet, or sub-plate using the built-in clamping slots provided.

To access the through holes, simply pick the edge of the protective

cap up and expose the C’ bored hole. Replace the cap after you have

mounted the vise to keep debris out of the holes. If you are mounting

the vise on it’s side or back to back, other clamping methods may be

required.

Additional clamping can be used, but may not be necessary. Please

be sure to exercise good judgment when securing your vise to the

mounting surface. Be sure your vise is secured and will not move when

applying the machine pressure.

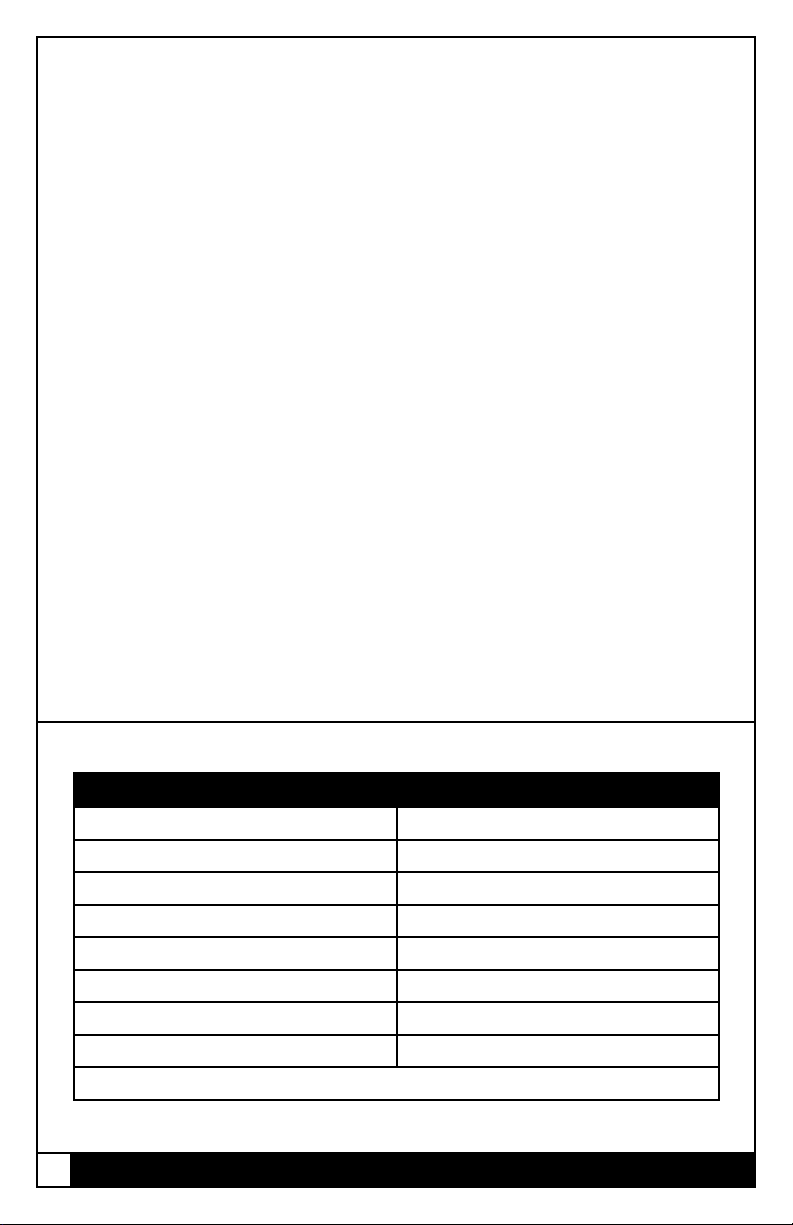

Manual Vise Clamping Force

Hydraulic PSI Hydraulic Series

400 1575

800 3150

1200 4725

1600 6300

2000 7875

2400 9450

2800 11025

3200 12600

Hydraulic displacement cu. In. 1.18