3 | ENLGISH

Table of Contents

Introduction .................................................................................................................3

Setup Instructions......................................................................................................4

Operating Instructions .........................................................................................5-7

DX6 Parts List ...............................................................................................................8

DX6 Mechanical Drawing........................................................................................9

Maintenance Schedule....................................................................................10-12

Troubleshooting Tips ............................................................................................. 13

Vise Data

Use this to ll out information about your vise for quick reference.

Purchase Date: _______ -_______- _______

Purchase Order: _______________________

Purchased From: _______________________

Delivery Date: _______________________

Serial No.: _______________________

Note:

Make sure to register your warranty online at kurtworkholding.

Introduction

Thank you for purchasing a Kurt DX6 vise. You have just purchased one

of the best machine vises in the industry. The outstanding accuracy

of this product is second to none. Backed by a lifetime warranty, this

product will last forever when used and maintained properly.

The original Kurt Anglock vises are designed for precision clamping on

basic machine tools such as knee-type mills, grinders and machining

centers. They can be used for, but are not limited to, operations like

precision boring, drilling, tapping, grinding & nishing.

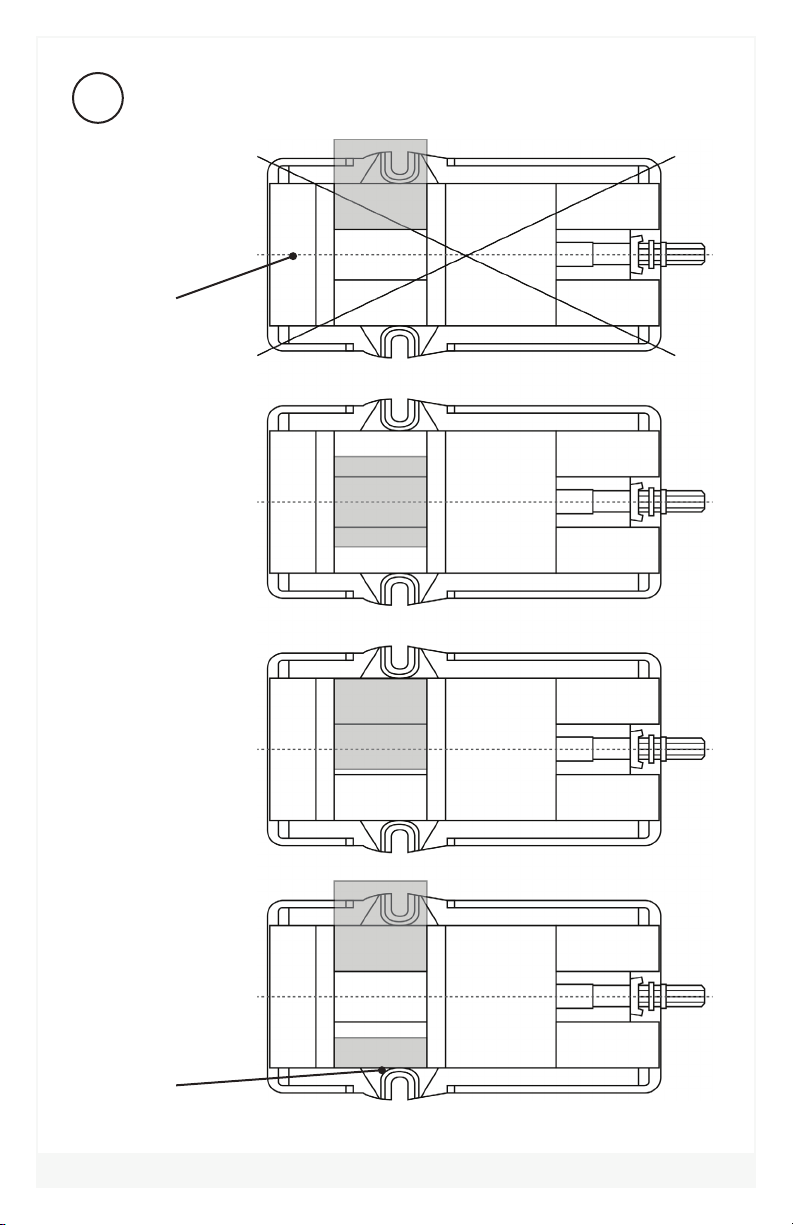

The patented Anglock design allows the movable jaw to advance in

such a way that each pound of force forward induces a ½ pound force

downward which minimizes the jaw lift and increases accuracy. This

combined with the needle bearings increases jaw clamping pressure.

Other features include: 80,000 psi ductile iron body, hardened vise bed

& jaw plates, semi-hard steel screw.

Table of Contents Introduction

machine tools such as knee-type mills, and machining centers. They can be

tapping, & finishing.

which minimizes the jaw lift and increases accuracy. This, combined with

the needle bearings, increases jaw clamping pressure. Other features

semi-hard steel screw.

the best machine vises in the industry. The outstanding accuracy of this

product is second to none. Backed by a lifetime warranty against

and maintained properly.