Kurz Instruments Inc. December 13, 2007

360210-AH Rev.A 504/534FTB Installation AH - 2

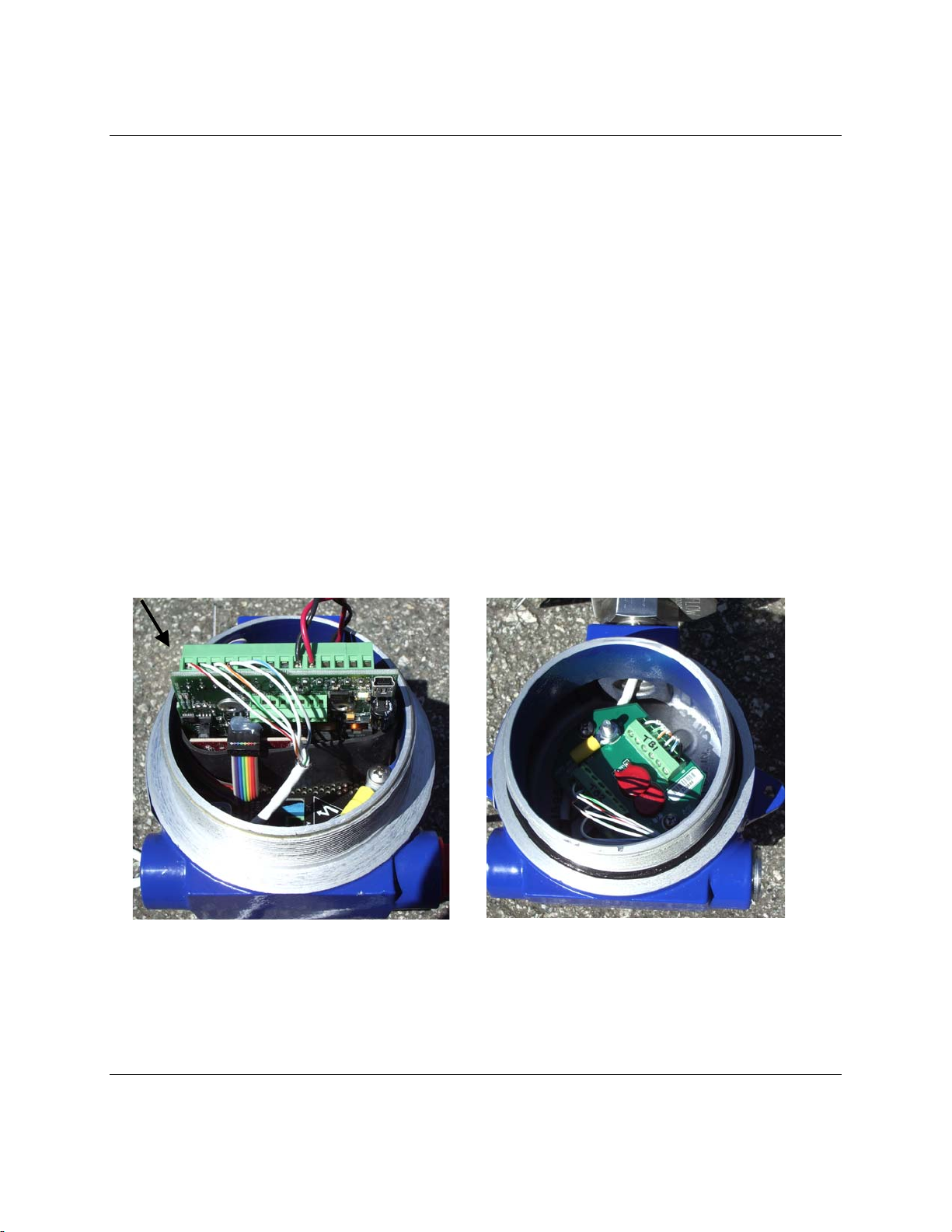

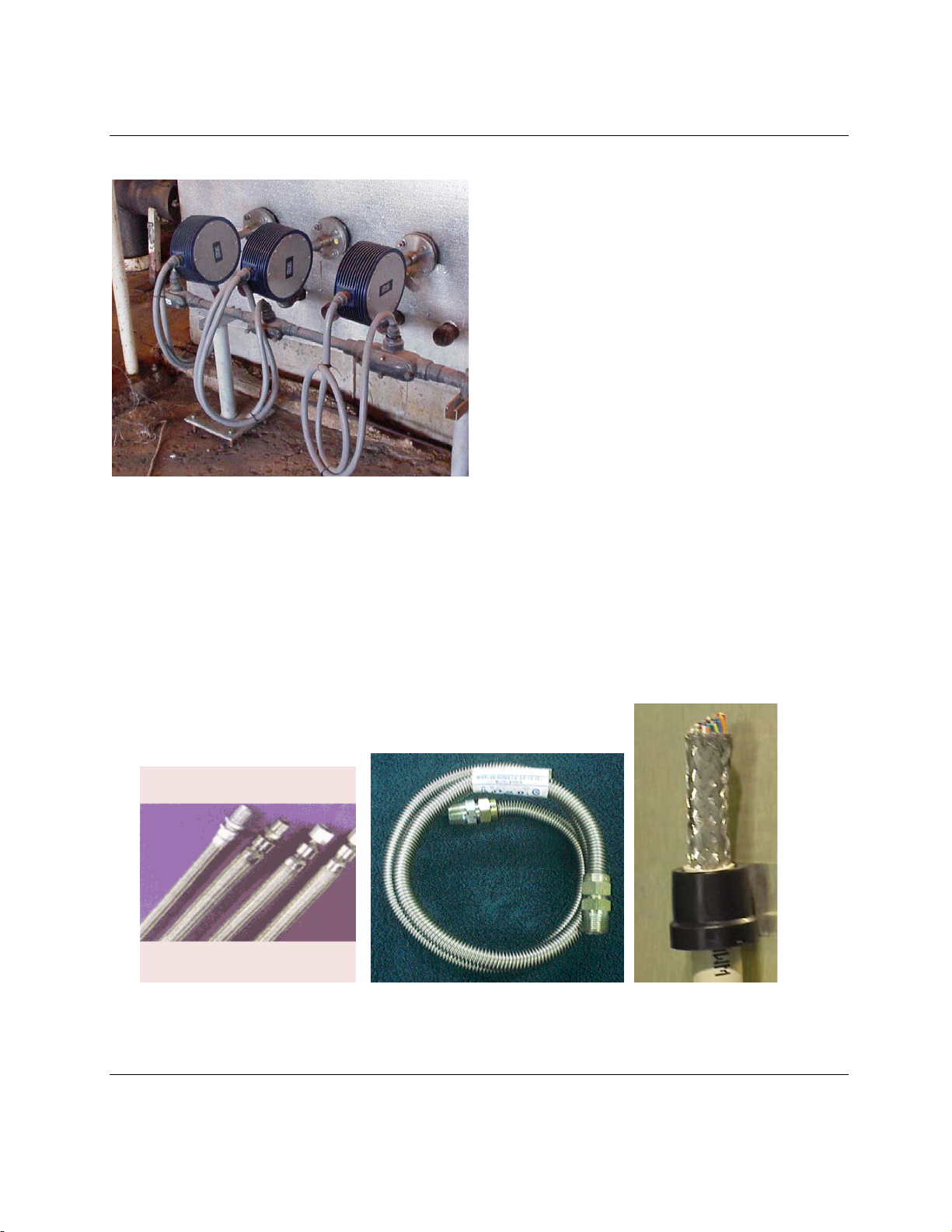

can be seen in the two photographs shown above.

•504FTB has only a small perforated plate flow conditioner. Requires straight

runs in the 15 to 40 D range to obtain field data with-in 2% of the laboratory

calibration. So field calibration may be needed depending on the accuracy

needed.

•534FTB has a venturi flow conditioner. This has no straight run requirements to

be within 2% of the laboratory calibration. Field calibration is generally not

needed.

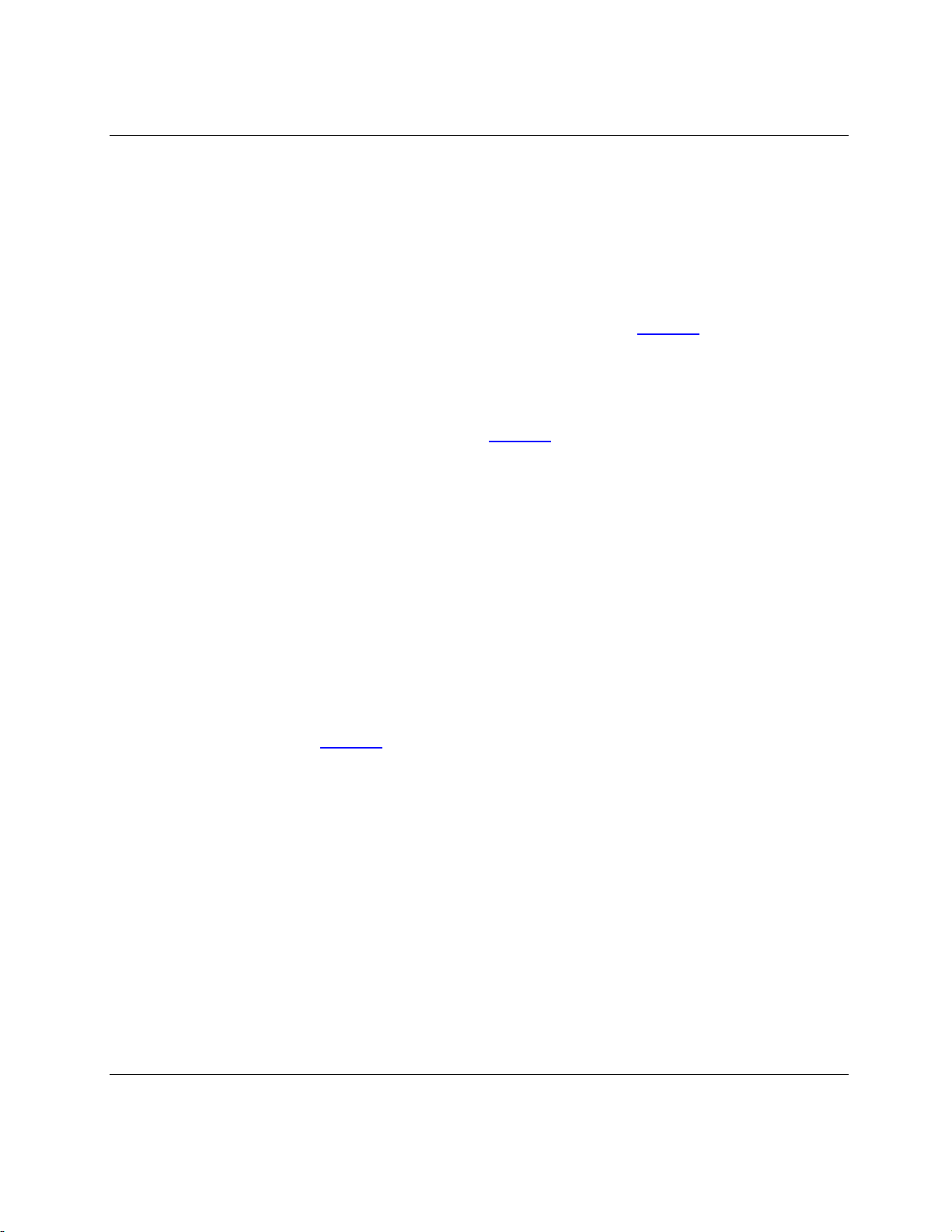

The quick start guide shows this very clearly in the second figure for in-line meters. In

addition to what is shown here, the double elbow case not shown, will introduce swirl

that can further aggravate the data and straight run length requirements.

Horizontal Mounted Meters

Any orientation works fine.

If there is condensate running along the bottom of the pipe, the sensor will last

longer if its electronics head is vertical up tilting down to no more than to 8 AM or

4 PM positions.

Vertical Mounted Meters

Flow going up works well under all conditions

Flow going down works well except near the zero flow region, below 50 SFPM or

0.25 SMPS.

High Dew Point applications

If the application is near the dew point, it will condense inside the pipe walls when

the gas is cooling as it flows along. Insulating the piping will reduce the condensate on

the inside walls. In these cases, it is best to mount the sensor from the bottom at about

7:30 or 4:30. Vertical from the top can cause water to flow on to the stings, or if

mounted from the bottom the condensate will aggravate sting corrosion. Condensate

(water or other liquids) on the sensor will cause false high flow readings while the

sensor evaporates the liquid.

Hot or cold process fluid

Insulation on the piping will reduce any temperature gradients that will introduce

a false high or low reading. Hot fluid in a pipe with cold walls will tend to read low for

sensors which are center line mounted and read high for Cold fluids in a warmer

ambient.