WARNINGS

Pay attention not to contact hot surfaces of the device!

Device is designed for professional use and must be used only by person who are trained for this intention.

Device is intended for cooking, do not use for another purpose.

In case of any failure, close the gas inlet valve of the device and disconnect electrical power.

Commission only authorized services for maintenance and use genuine spare parts.

Before starting to use the device, carefully clean the surfaces especially those to be in contact with foods.

ATTENTION: Do not use the device for grilling. Never operate when the cooking chamber is empty.

During first operation, device will emit fume and smell for a short period. This fume and smell is the result of the

insulation material and the substances such as oil, etc. on the metal sheet surfaces. This is not dangerous and will

disappear by itself.

Operate the device at the highest operation level for 1 hour during first operation.

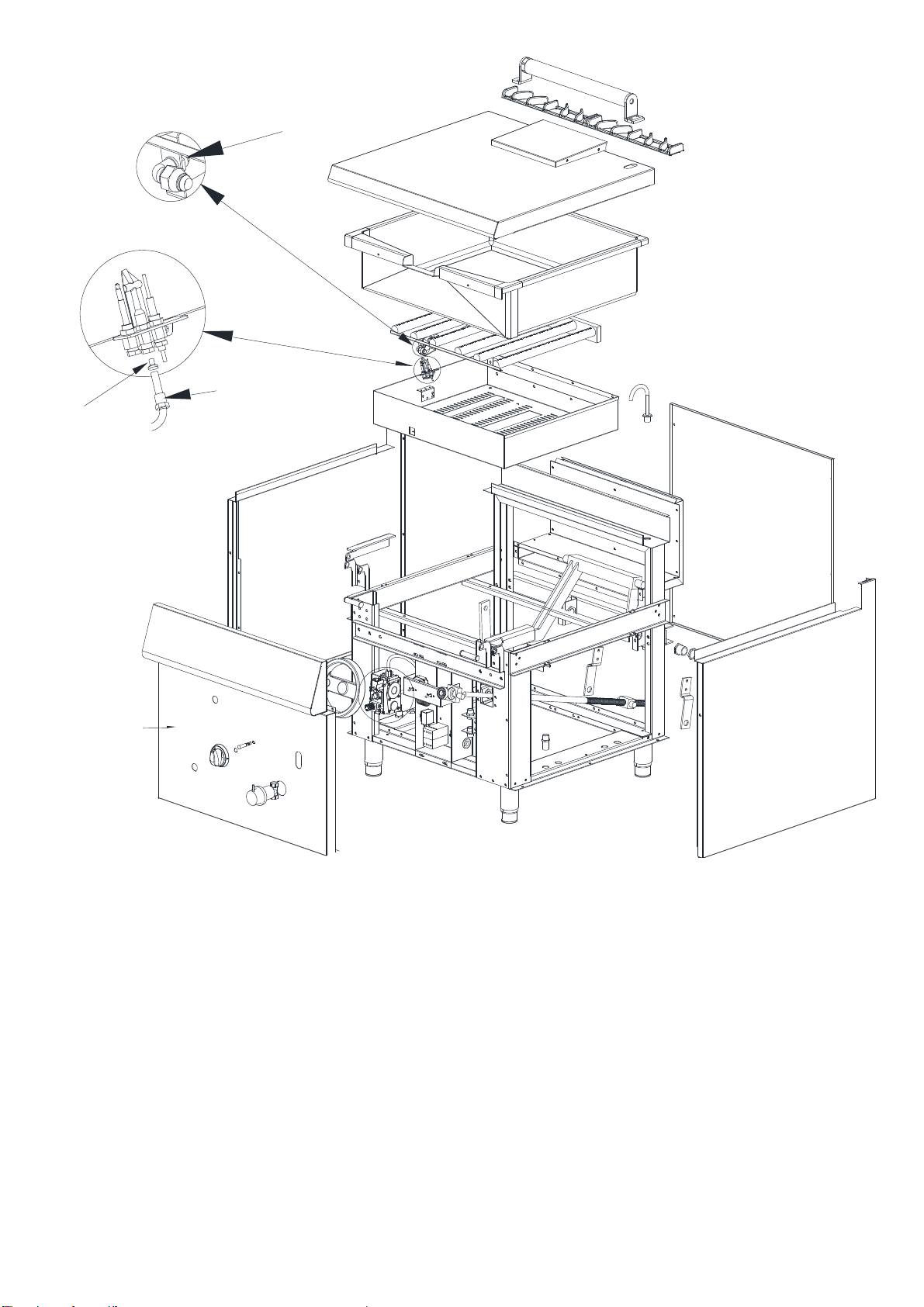

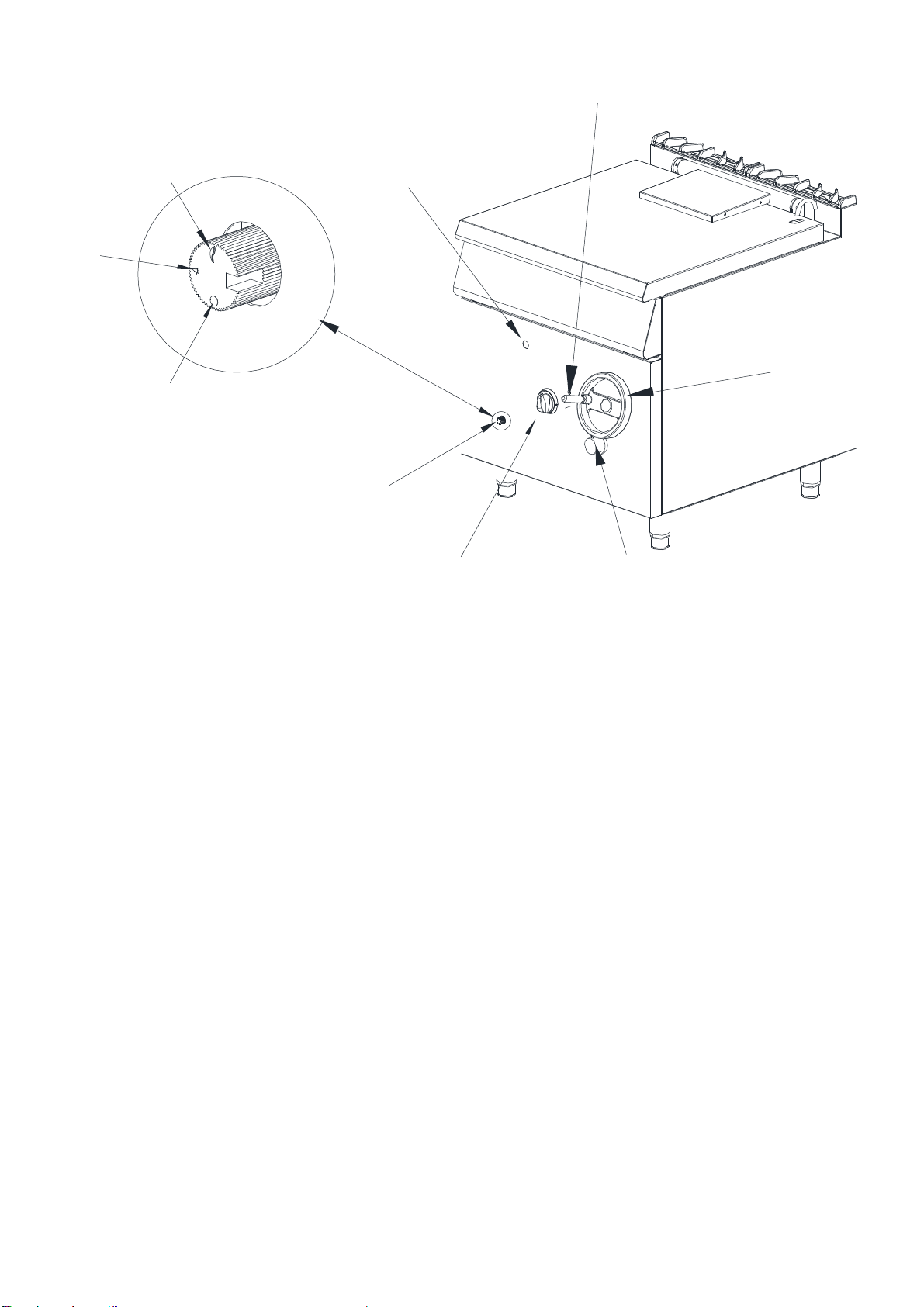

Additional safety members

Safety thermostat cuts off the gas feeding to the burners and ceases operation in case pan temperature exceeds

maximum controlling temperature due to thermostat failure. In this case, close the gas inlet valve of the device and

notify to the authorized service.

When the pan is lifted during the operation of the device, microswitch cuts off the gas and switches off burners.

CLEANING and MAINTENANCE

Do not wash the device with high pressurized water.

You must switch off the gas and electrical connection of the device before starting to cleaning or maintenance

activities.

Before it cools down completely, wipe the device with a cloth immersed in warm soapy water at the end of each

working day.

During cleaning the device surface, do not use corrosive material which may cause scratches on the surface such as

detergents, wire brushes, etc.

Clean the surfaces, which cannot be cleaned through abovementioned methods, with chemical solvents.

If the device will not be used for a long period, coat the surfaces with a thin layer of Vaseline.

In case of any extraordinary condition with the device, notify to the authorized service. Never allow unauthorized

people to interfere in the device.

Lubricate pan lifting system with heat-resistant grease semi-annually.

POSSIBLE PROBLEMS - SOLUTIONS

Pilot burner does not ignite or ignites with difficulty.

Gas inlet pressure is insufficient.

Gas pipe or nozzle is blocked.

Gas tap is faulty.

Piezoelectric ignition system is faulty.

Safety thermostat is faulty.

Pilot burner goes out during operation.

Gas tap is faulty.

Safety thermostat is faulty or defective.

Main burner does not ignite or ignites with difficulty.

Gas pressure is insufficient.

Nozzle is blocked.

Gas tap is faulty.

Thermostat is faulty.

Pan lifting micro switch is faulty.

Temperature control cannot be performed.

Gas tap is faulty.

Thermostat is faulty.

Pan lifting micro switch is faulty.