3

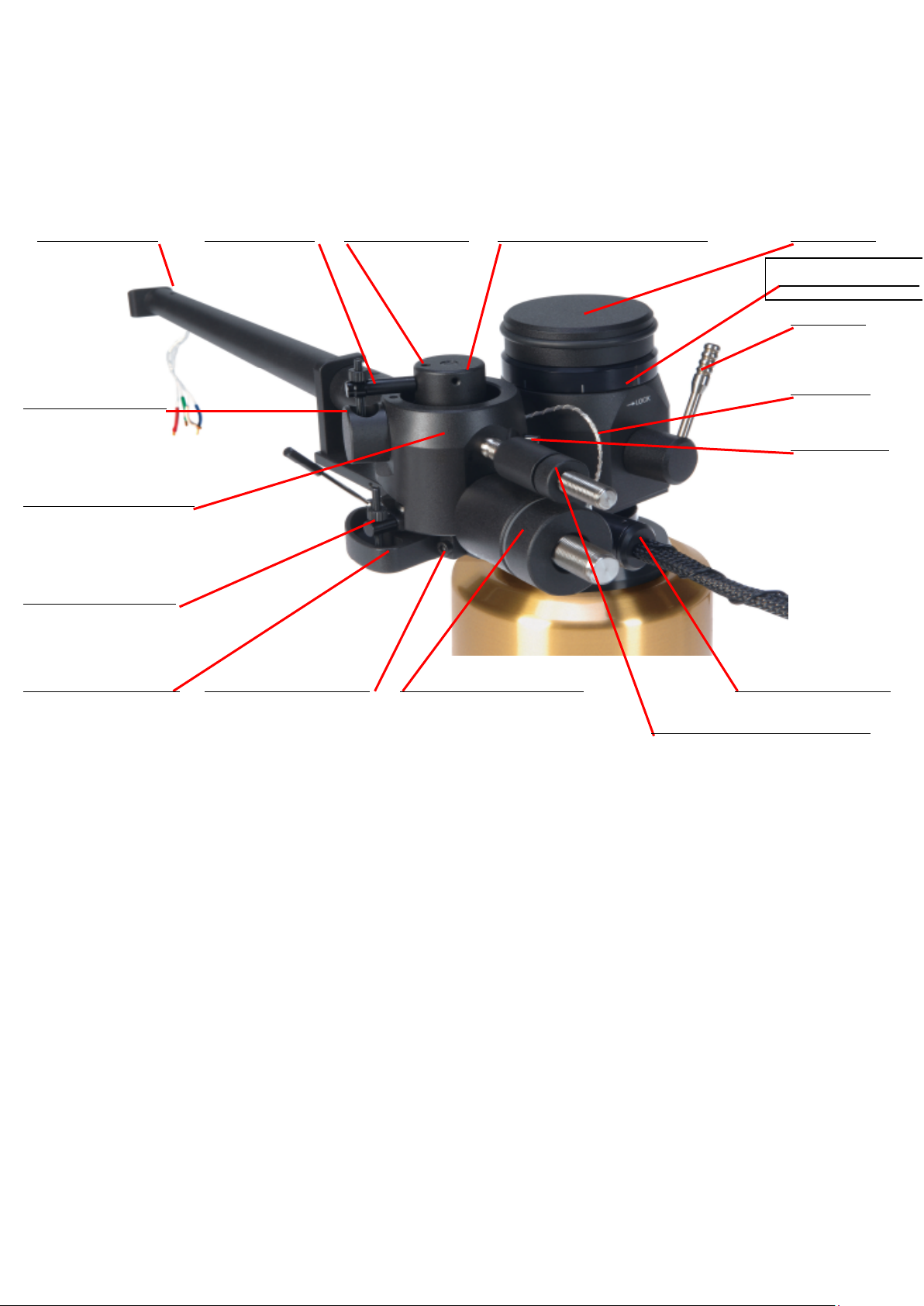

General description

This di ers rom other arms by incorporating several unique eatures. The zero play bearing

is con igured on 4 points. There is very precise VTA adjustment and, despite a longer

e ective length o 280 mm (11 inches), its the standard mounting distance o 212mm ( or 9

inches arms).

The heart o the new construction is a unique 4 point bearing. The irst set o two points

(similar to a double unipivot bearing) allows vertical movement. The second set o two points

allows horizontal movement. All our points have minimal riction and zero play in all

playing directions thus ensuring the cartridge plat orm and the cartridge itsel move with very

low riction and minimal vibration across the record. It is normal to eel slack in the bearings

in certain directions.

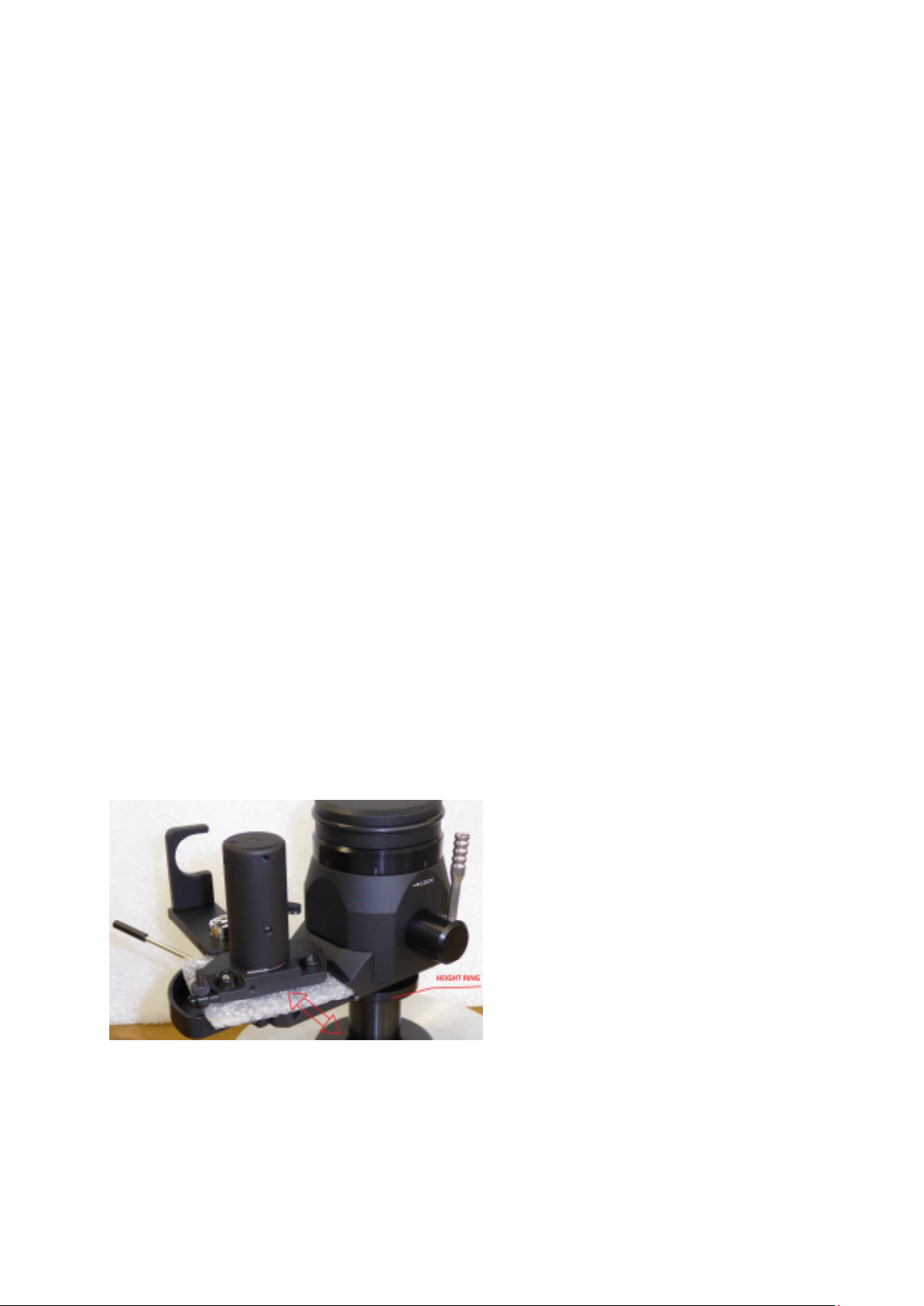

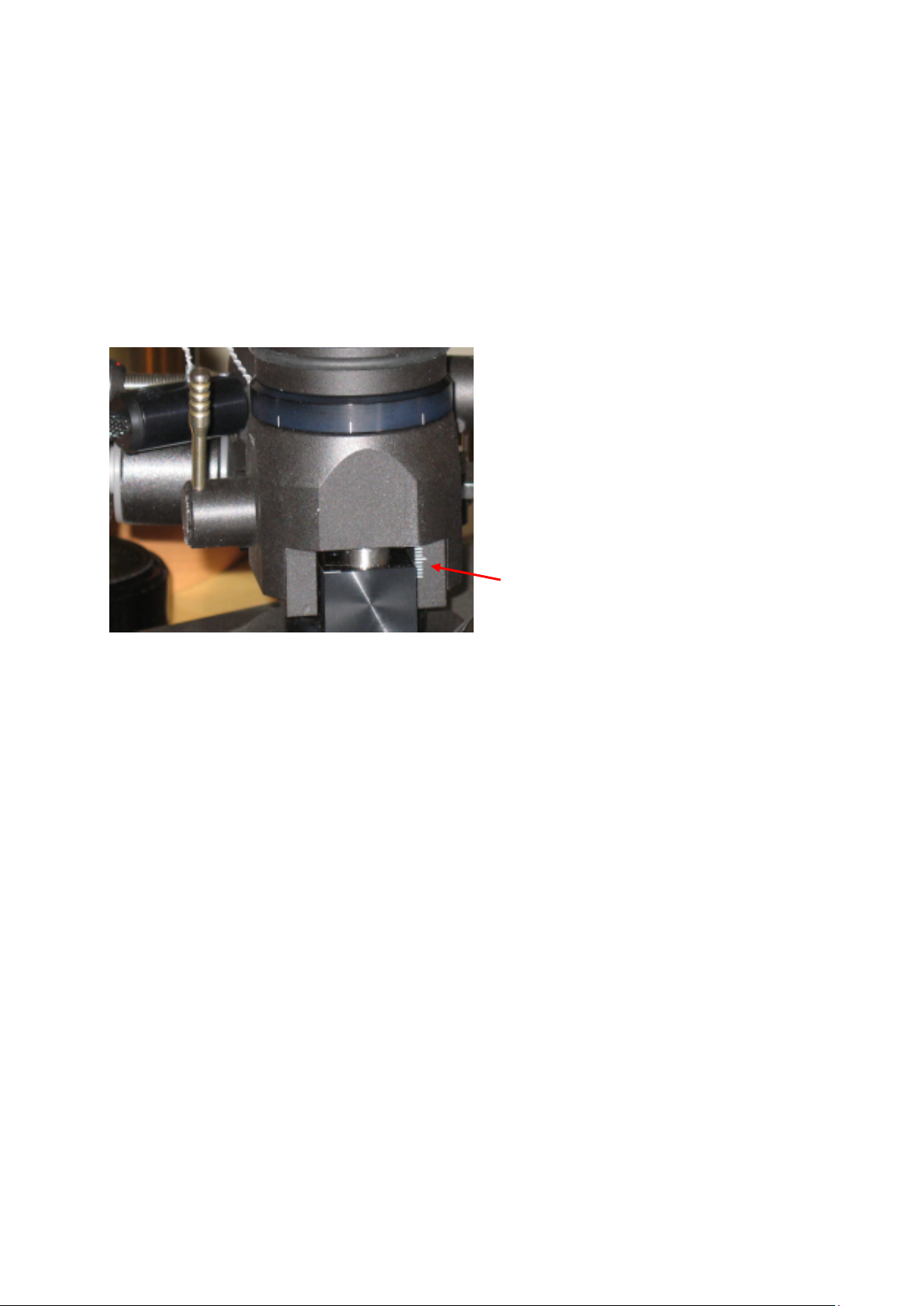

The whole construction is mounted on a rigid VTA tower which allows very precise VTA

adjustment while playing, without any loss o rigidity, yet with up to 0.01 mm o precision

and zero play.

The main tube is constructed and machined rom solid aluminium, similar to our tangential

Air line arm. The main counterweight balances the tonearm and there is a second small

counterweight with which the tracking orce can be inely adjusted. Azimuth can be adjusted

in small repeatable increments with zero play, by means o an Allen key.

A eature o the tonearm is a unique detachable headshell( one spare included as standard).

The electrical connection is via standard pins but the headshell can be simply removed by

unscrewing with an Allen key. The headshell is ixed with a precise hexagonal locking

system giving the same rigidity as with a ixed headshell.

Two separate troughs damp vertical and horizontal resonances and can be inely adjusted

independently. The troughs can be removed rom the tonearm.

Internal wiring is o superior special alloy silver wires. One set o 4 wires runs unbroken

rom the cartridge pins to the RCA plugs.

Product registration and warranty extension

Kuzma products have a non trans erable 2 year limited warranty on parts and labour, which

may vary in each country.

To obtain the 5 years* limited warranty rom us, you need to register the product on our web

site within 30 days o purchase. We suggest registration o products in any case because this

will also help you to receive our technical support more easily and with resale o products.

Simply register on our web site, complete the orms and you will receive an extended ive

year warranty card on your email within a ew days. * not valid or ex demo products.