1

1. INTRODUCTION

As the world leader in high technology ceramic/silica

applications, Kyocera has stepped into the forefront in

development of multicrystalline solar modules. Kyocera

began researching photovoltaics in 1975 and has

supplied many thousands of modules throughout the

world since 1978. Its years of experience and state-of-

the-art technology have produced quality solar modules

in a range of sizes to meet the energy needs of the

growing solar market.

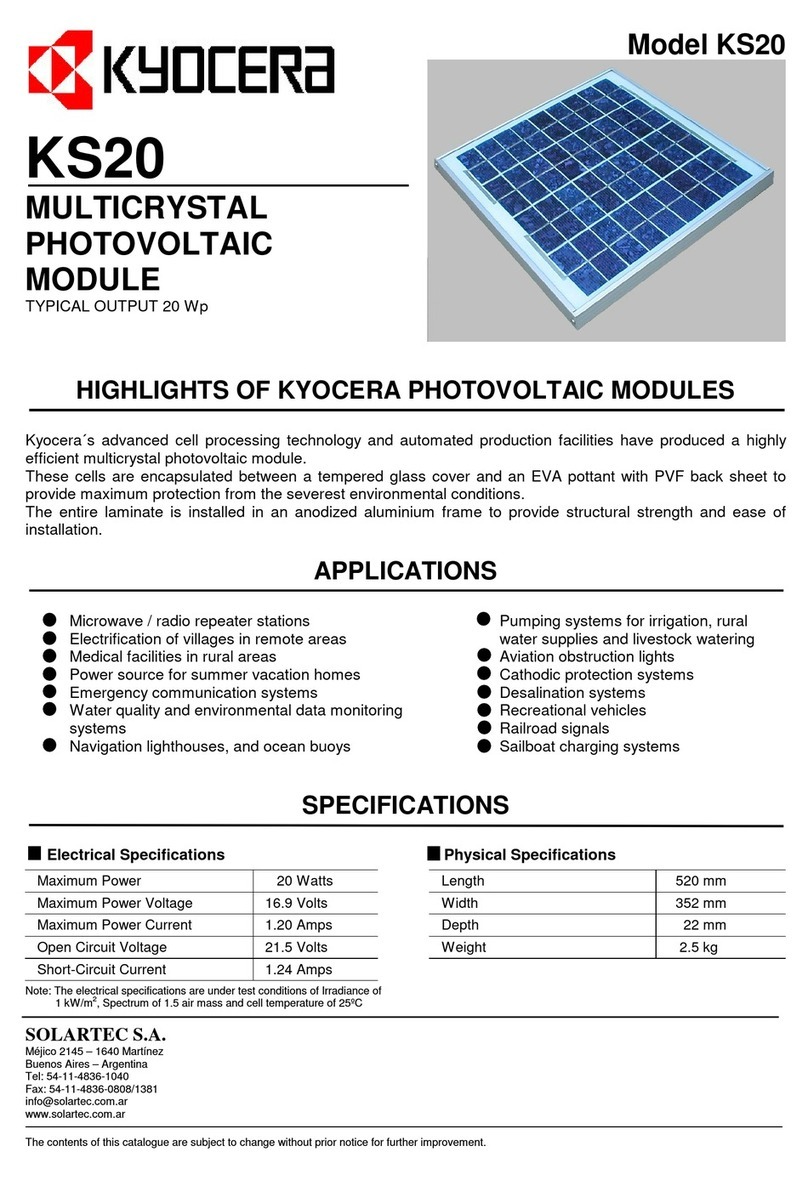

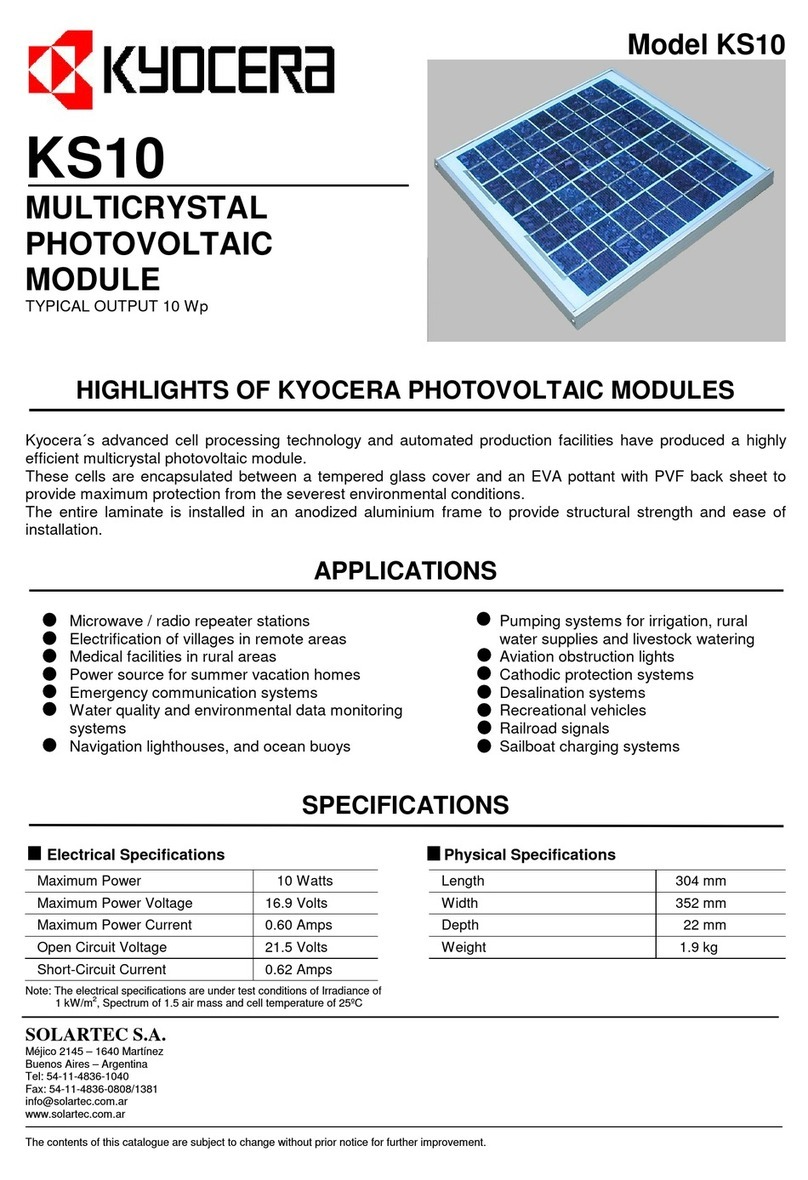

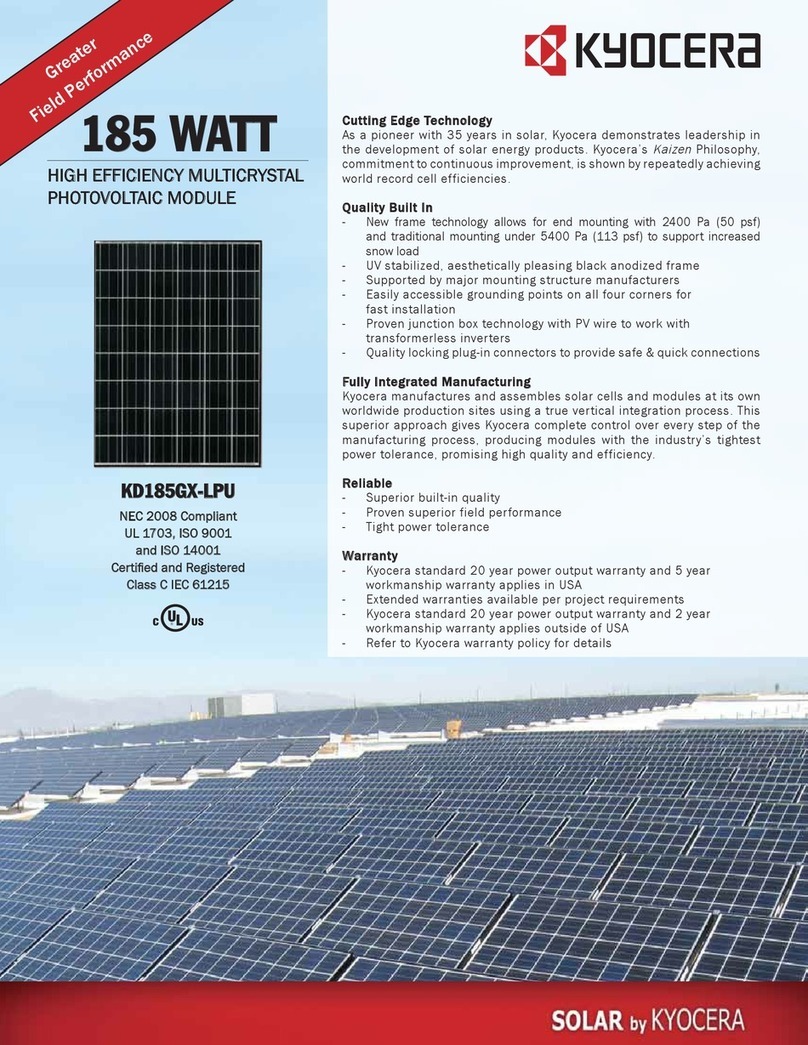

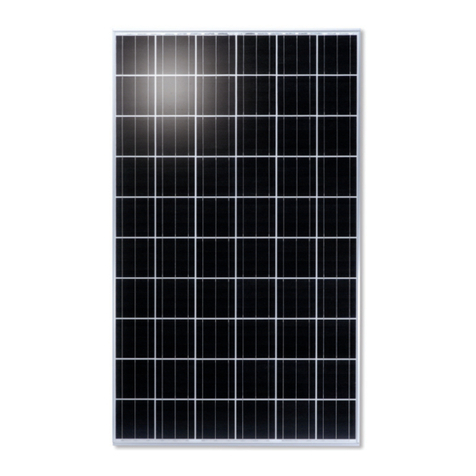

2. POWER MODULES

Kyocera "KC" series modules come in various sizes to

satisfy a full range of applications. Each module is made

of multi- crystalline cells manufactured by the "casting"

method. These cells cover nearly 100% of the module's

surface. To protect the cells from the most severe-

environmental conditions, they are encapsulated

between a tempered glass cover and an EVA pottant

with PVF back sheet. The entire laminate is installed in

an anodized aluminum frame for structural strength and

ease of installation.

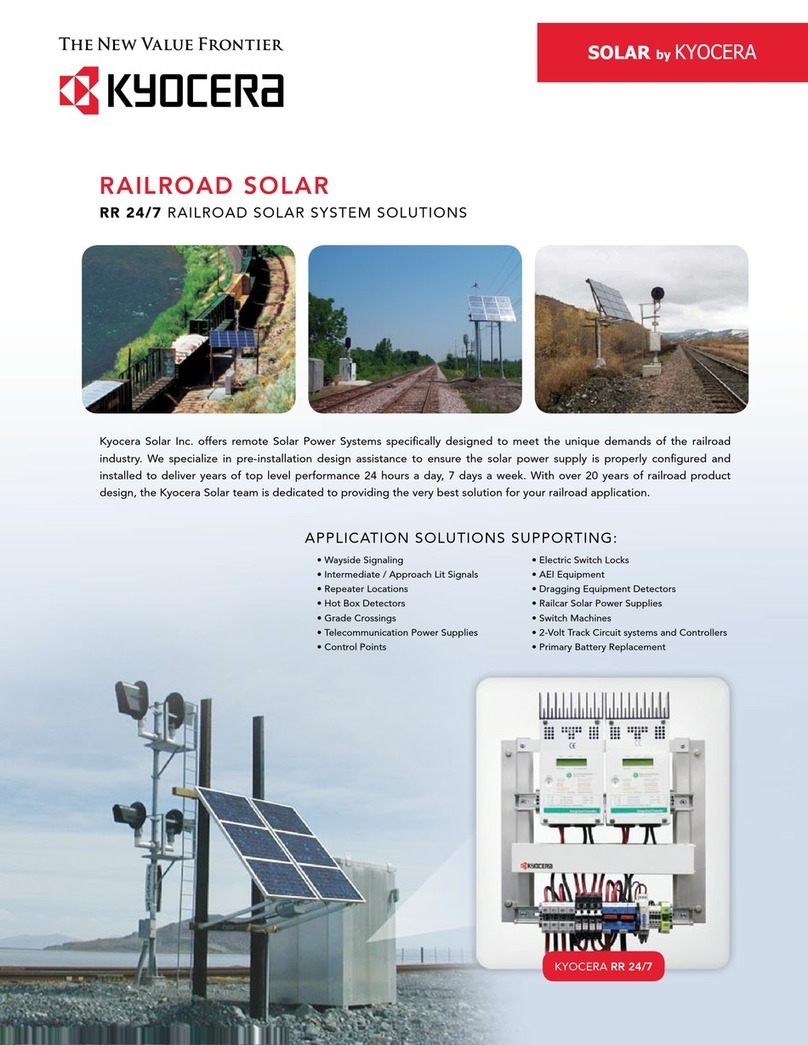

3. APPLICATIONS

Kyocera modules are a reliable, virtually maintenance

free power supply, designed to operate efficiently in

sunlight. Kyocera solar modules are ideal for charging

storage batteries used to power remote homes,

recreational vehicles, boats, telecommunication systems

and other electric generation application.

4. MOUNTING SITE SELECTION

The solar modules should be mounted in a location

where they will receive maximum sunlight throughout the

year. In the Northern Hemisphere, the modules should

face south, and in the Southern Hemisphere, the

modules should face north. Modules facing 30 degrees

away from true South (or North) will lose approximately

10 to 15 per cent of their power output. If the module

faces 60 degrees away from true South (or North), the

power loss will be 20 to 30 per cent. When choosing a

site, avoid trees, buildings or obstructions which could

cast shadows on the solar modules especially during the

winter months when the arc of the sun is lowest over the

horizon.

5. MODULE TILT ANGLE

Solar modules produce the most power when they are

pointed directly at the sun. For installations where the

solar modules are mounted to a permanent structure,

the solar modules should be tilted for optimum winter

performance. As a rule, if the system power production

is adequate in the winter, it will be satisfactory during the

rest of the year. The module tilt angle is measured

between the solar modules and the ground (Figure 1).

6. MOUNTING THE MODULE

The frame of each module has fourteen 7 mm

Ú

diameter mounting holes (Figure 2). These are used to

secure the modules to the supporting structure. The

example of a ground mounted structure is shown in

Figure 3. The four holes close to the corners of the

module are most often used for mounting. Clearance

between the module frame and the mounting surface

may be required to prevent the junction box from

touching the surface, and to circulate cooling air around

the back of the module. In case the modules will be

mounted on the roof or wall of a building, the standoff

method or the rack method are recommended.

STANDOFF: The modules are supported parallel to the

surface of the building wall or roof. Clearance between

the module frames and surface of the wall or roof is

required to pre- vent wiring damage and to allow air to

circulate behind the module.

The recommended standoff height is 4.5 in. (about 115 mm)

If other mounting means are employed, this may affect

the Listing For Fire Class Ratings.

RACK: The supporting frame is used to mount modules

at correct tilt angles. The modules are not designed for

integral mounting as part of a roof or wall. The mounting

design may have an impact on the fire resistance.

INSTALLATION MANUAL

FOR KYOCERA SOLAR MODULE

KC-TYPE SERIES

Please read this manual carefully before

installing the modules.

KYOCERA CORPORATION