3.3 Tip Position for setting and removing

3.3 Tip Position for setting and removing3.3 Tip Position for setting and removing

3.3 Tip Position for setting and removing

3.4 Teaching for tip setting and removing

3.4 Teaching for tip setting and removing3.4 Teaching for tip setting and removing

3.4 Teaching for tip setting and removing

Preparations and precautions before operation

Preparations and precautions before operationPreparations and precautions before operation

Preparations and precautions before operation

1.Cut off the air supply when inserting or removeing tips by manual during test-driving.

2. Make sure that the machine is fixed on stand tightly.

3. Confirm the shank is joined tightly to the gun arm.

4. Check cap tips can be matched with the inside diameter of the removing part, the magazine inside diameter and the depth.

5. Confirm the connection of the air supply.

6.Check air cylinder operation and chucking rotation movement. (Test driving also possible)

7.Charge the cap tip which fits to the magazine.

8.Remove the cap tip from the magazine manually and confirm that next captip comes to the fixed position.

Operatation

OperatationOperatation

Operatation (Removing)

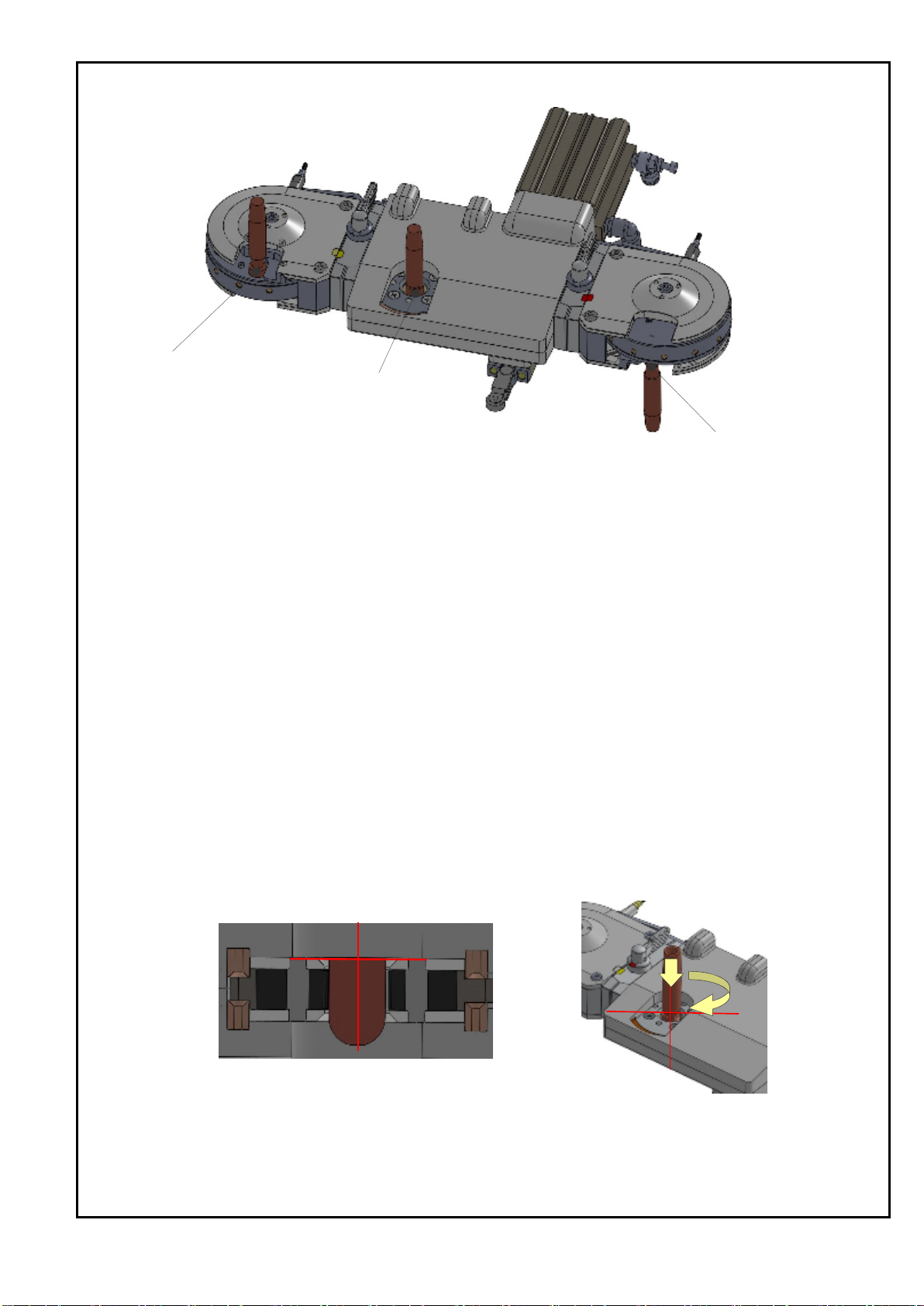

1.Position cap tips to the center of the removing part by teaching robot.

2.Confirm the center position of removing and move to the Z axial direction(up or down). ※Be careful about collision.

3. Memorize the location where the cap tip has almost entered in the remover.

4.Operate cylinder.(=The remover starts roatating)

5. 0.5 seconds after beginning of cylinder operation, move a robot back in the Z axial direction, 3mm.

*

**

*Please do the below action, since the cap tip can NOT be removed by only the rotation of the remover.

Please do the below action, since the cap tip can NOT be removed by only the rotation of the remover. Please do the below action, since the cap tip can NOT be removed by only the rotation of the remover.

Please do the below action, since the cap tip can NOT be removed by only the rotation of the remover.

(Upper→Raise about 3mm, Lower→Lower about 3mm)

(Upper→Raise about 3mm, Lower→Lower about 3mm) (Upper→Raise about 3mm, Lower→Lower about 3mm)

(Upper→Raise about 3mm, Lower→Lower about 3mm)

This action also prevents the robot gun and the KIKK from being damaged.

This action also prevents the robot gun and the KIKK from being damaged. This action also prevents the robot gun and the KIKK from being damaged.

This action also prevents the robot gun and the KIKK from being damaged.

The position of the cylinder switch needs to be re-adjusted when confirming the operation of the KIKK.

The position of the cylinder switch needs to be re-adjusted when confirming the operation of the KIKK. The position of the cylinder switch needs to be re-adjusted when confirming the operation of the KIKK.

The position of the cylinder switch needs to be re-adjusted when confirming the operation of the KIKK.

6.After the cap tip has removed from the shank, please return the cylinder.

7. Check the captip fell off

Tips for operation

Tips for operationTips for operation

Tips for operation

1.Movement timing of Z axial direction can be changed depending on the operation speed of the cylinder.

※Tip will not be removed when operation above has not been done.

*From the cylinder operation start to finsh, please adjust the time to approx. 1.5sec.

*From the cylinder operation start to finsh, please adjust the time to approx. 1.5sec.*From the cylinder operation start to finsh, please adjust the time to approx. 1.5sec.

*From the cylinder operation start to finsh, please adjust the time to approx. 1.5sec.

(It can be adjusted by using the speed controller on the cylinder)

(It can be adjusted by using the speed controller on the cylinder) (It can be adjusted by using the speed controller on the cylinder)

(It can be adjusted by using the speed controller on the cylinder)

2.For short length of cap tips, confirm the part of tip body to decide the inserting postiotion.

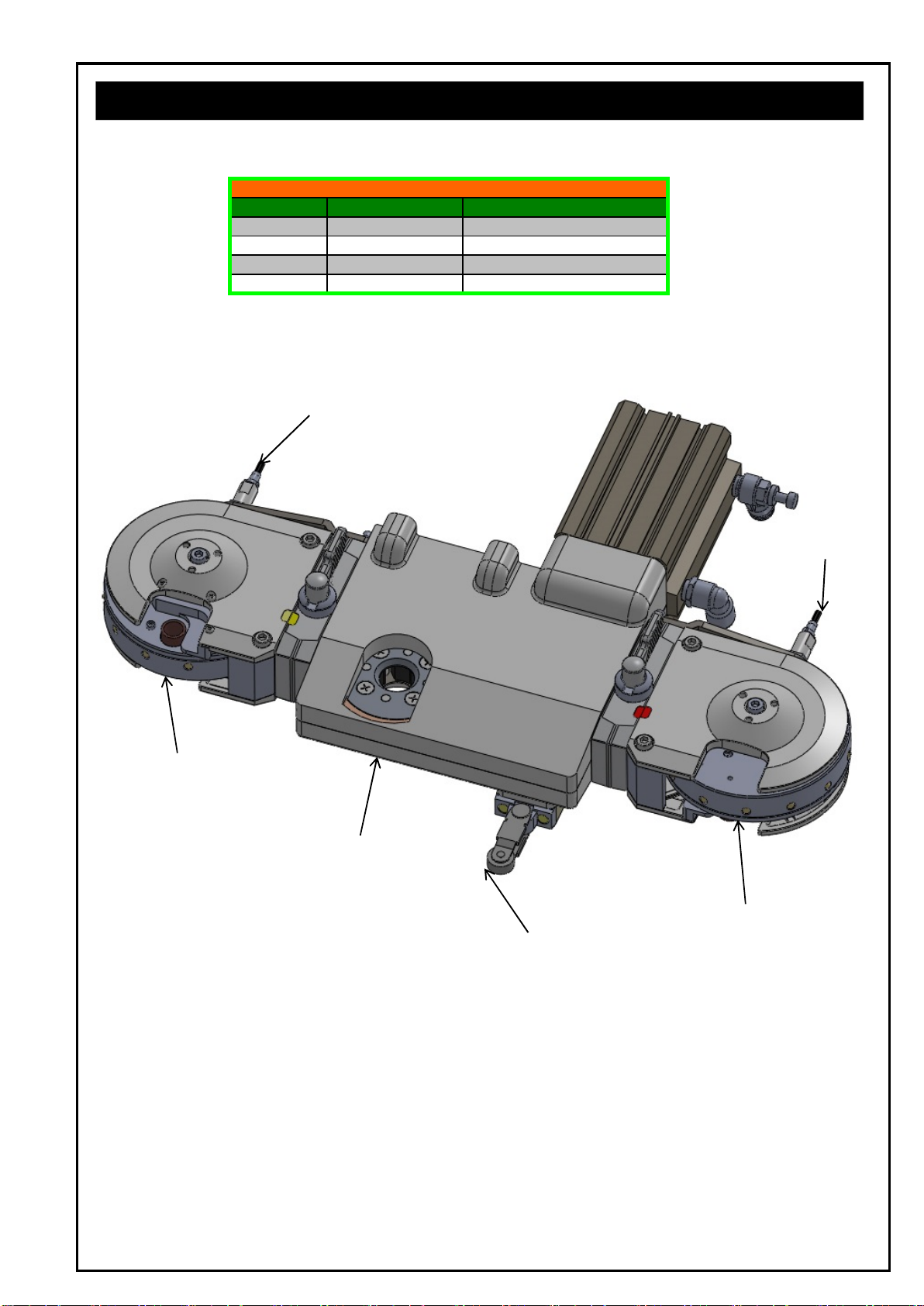

Upper tip setting part

Lower tip setting part

Tip removing part

10 ページ