다기능 디지털 복합 보호계전기 K-PAM 5500 Series

14 15

Kyongbo Electric Co., Ltd.

Digital Integrated Protection Relay K-PAM 10 Series

Protection Relay Element Setting Method

▶ OCGR Setting Method

① After selecting ‘OCGR (50N/51N)’ in Protection Relay Element Setting Method ③, press the RIGHT (

) Key to

enter the setting screen.

② Use the UP ( ), DOWN ( ) KEY to move the category you want to set, and then enter the ENTER (

ENTER

)

KEY to pop up the password input screen. (initial password 0000)

③ Use the UP ( ), DOWN ( ) KEY to change the setting value and then input ENTER (

ENTER

) KEY.

④ After completing the setting, input the LEFT (

) KEY to check whether the setting has been changed.

When ENTER (

ENTER

) KEY is input, the setting is saved, and when ESC (

ESC

) KEY is input, the setting is canceled.

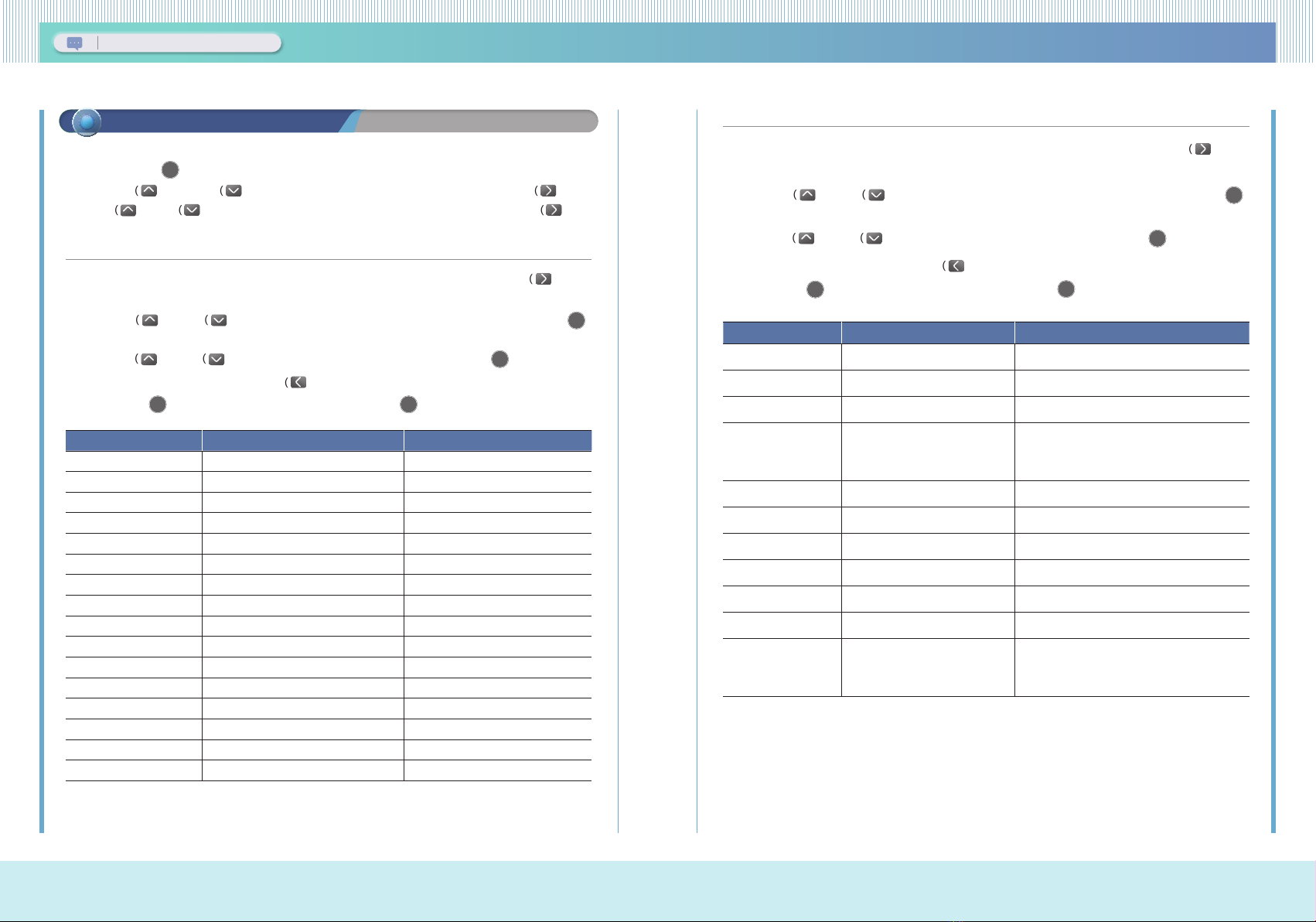

Category Setting Range Description

FUNCTION DISABLED, ENABLED Whether to use the function

ID NAME 8 ASCII Characters Protection element name setting

ALGORITHM PHASOR, RMS Relay calculation method setting

PICKUP 0.02 ~ 20.00pu (0.01pu STEP) Pickup setting

MODE INST, DT, INV Operation mode setting

TIME DELAY 0.04 ~ 60.00s (0.01s STEP) Operation delay time setting

CURVE IEC_NI, .... IEEE_MI Inverse curve setting

LEVER 0.01 ~ 10.00 (0.01 STEP) Inverse lever setting

RESET DLY 0.00 ~ 60.00s (0.01s STEP) Reset delay time setting

BLOCK NONE, .... R/I16 Protection blocking condition setting

DO1-CB OPN DISABLED, ENABLED DO1 setting

DO2-CB CLS DISABLED, ENABLED DO2 setting

DO3 DISABLED, ENABLED DO3 setting

DO4 DISABLED, ENABLED DO4 setting

LED NONE, ALARM, LED#1 ~ #8 LED setting

EVENT DISABLED, OP, PKP+OP, OP+RST, ALL EVENT record setting

Category Setting Range Description

FUNCTION DISABLED, ENABLED Setting whether to use the function

ID NAME 8 ASCII Characters Protection element name setting

ALGORITHM PHASOR, RMS Relay calculation method setting

SOURCE 3I0, NCT

Zero sequence current source setting

3I0 : Internal calculation

NCT : N phase current

PICKUP 0.02 ~ 20.00pu (0.01pu STEP) Pickup setting

MODE INST, DT, INV Operation mode setting

TIME DELAY 0.04 ~ 60.00s (0.01s STEP) Operation delay time setting

CURVE IEC_NI, .... IEEE_MI Inverse curve setting (12ea)

LEVER 0.01 ~ 10.00 (0.01 STEP) Inverse lever setting

RESET DLY 0.00 ~ 60.00s (0.01s STEP) Reset delay time setting

I1 RESTRAINT DISABLED, ENABED

Setting whether to use the current restraint

function

※ Excluding single phase relay

- Among the OCR setting methods, BLOCK ~ EVENT setting category are the same setting category for all protection

elements.

① Press the MENU(

MENU

) key on the initial screen

② Use the UP ( ) and DOWN ( ) keys to select ‘1. RELAY SETTING’ category, then input RIGHT (

) Key.

③ Use UP ( ), DOWN ( ) KEY to select the protection relay element to be set and then input the RIGHT (

) Key.

▶ OCR Setting Method

① After selecting ‘OCR1 (50/51)’ in Protection Relay Element Setting Method ③, press the RIGHT (

) Key to

enter the setting screen.

② Use the UP ( ), DOWN ( ) KEY to move the category you want to set, and then enter the ENTER (

ENTER

)

KEY to pop up the password input screen. (initial password 0000)

③ Use the UP ( ), DOWN ( ) KEY to change the setting value and then input ENTER (

ENTER

) KEY.

④ After completing the setting, input the LEFT (

) KEY to check whether the setting has been changed.

When ENTER (

ENTER

) KEY is input, the setting is saved, and when ESC (

ESC

) KEY is input, the setting is canceled.