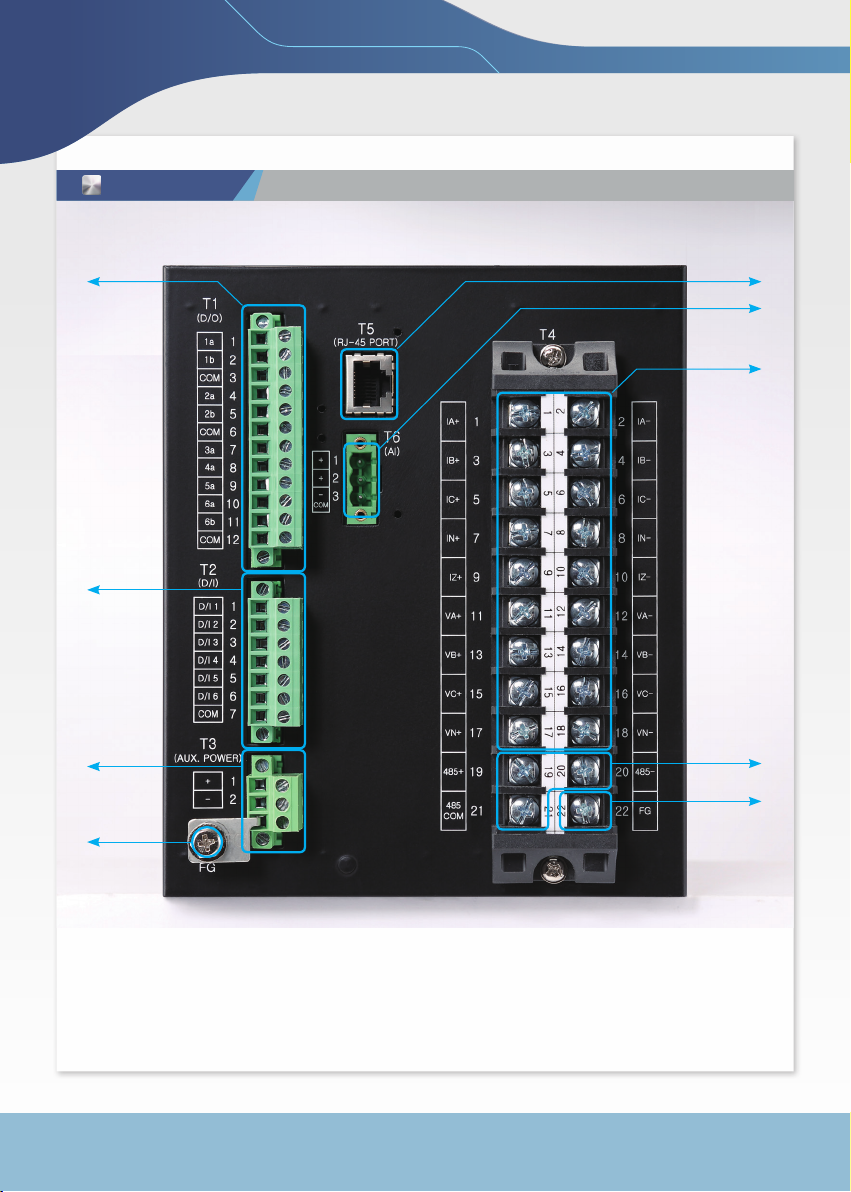

Digital Integrated Protection Relay K-PAM 5500 Series

7

Num Category Description

①Status LED

•RUN (GREEN)

- Lights up when the relay is running

•ERROR (RED)

- Lights up when an error occurs as a result of the relay system self-diagnosis

•PICK UP (YELLOW)

- Lights up when the protection relay element is PICK-UP

•TRIP (RED)

- Lights up when the protection relay element is TRIP

•ALARM (YELLOW)

- Lights up when conditions are satisfied by connecting logic

②TFT-LCD •Screen Display

③Local/Remote

Control Button

•L/R Key (LOCAL/ REMOTE Key)

- Used when selecting control operation between Local and Remote

④Custom LED • Use of LED desired by the user through setting of relay protection

element operation, etc.

⑤Button

(UP Key)

- Used to move upwards in a menu category or screen,

increase a number when setting, or change a setting

(Down Key)

- Used to move down on a menu category or screen,

decrease a number when setting, or change a setting

(Right Key)

- Used to move from the menu to the upper menu or to the right when setting

(Left Key)

- Used to move from menu to sub-menu, or to move to the left when setting

MENU Key

- Used to enter the main menu from the initial screen

ESC Key

- Used to cancel setting when setting is in progress or to cancel test in progress

RESET Key

- Displayed as Annunciator Reset when connecting to Logic

- Generally used when reset protection elements OP, LED, and D/O

ENTER Key

- Used to save setting changes or to execute control.

⑥CB Close/Open

Control Button

OPEN Key

- Used when opening CB

CLOSE Key

- Used when closing CB

⑦USB-A Type Port •USB port for connecting relay management software

MENU

ESC

ENTER

OPEN

CLOSE

RESET