r

•

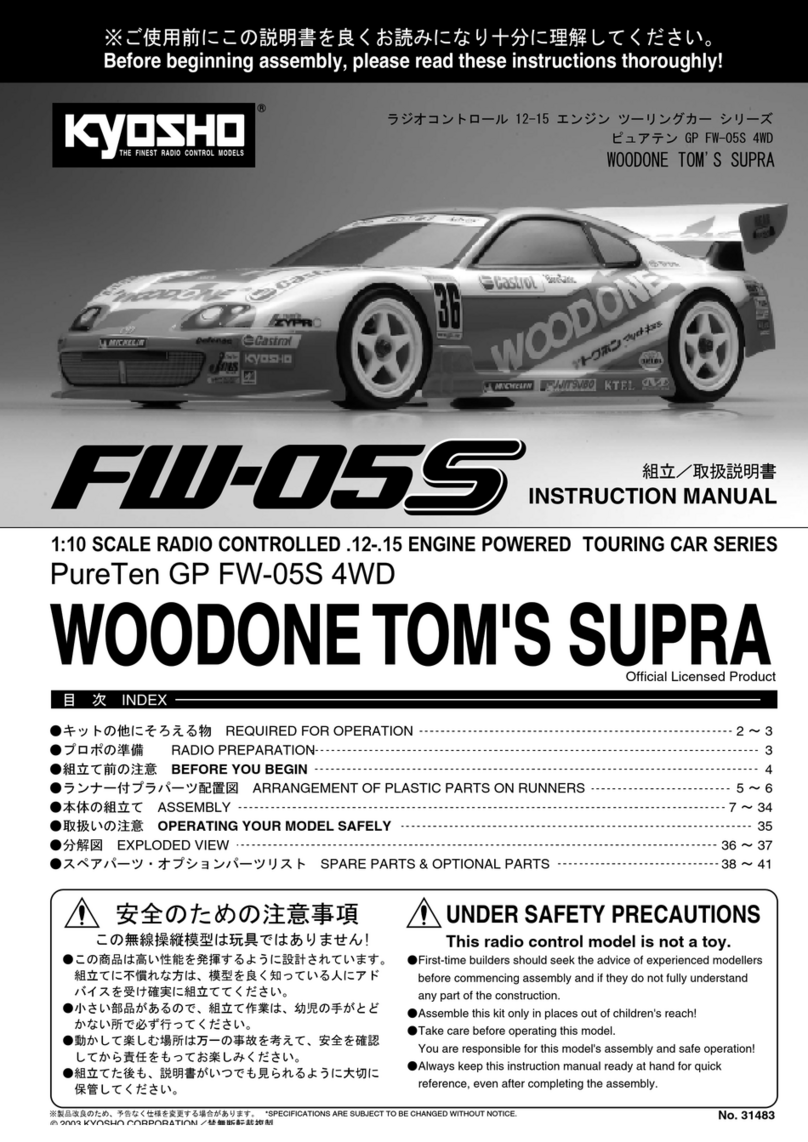

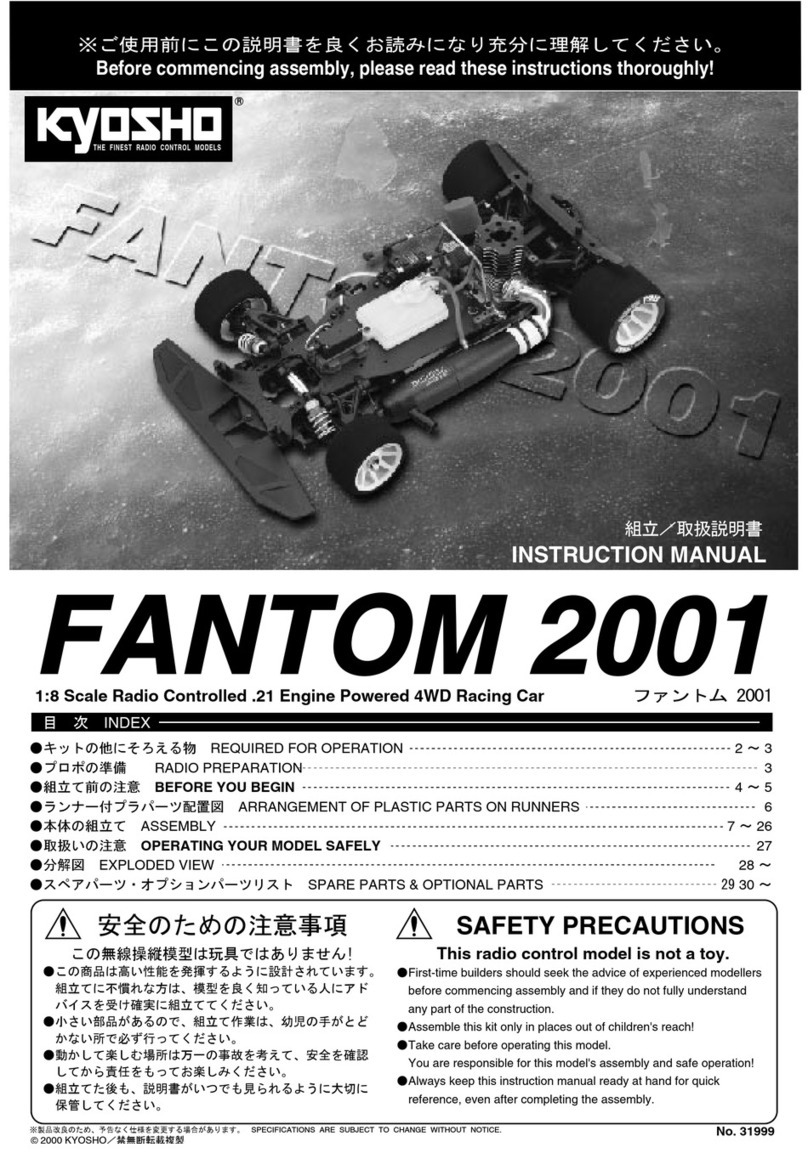

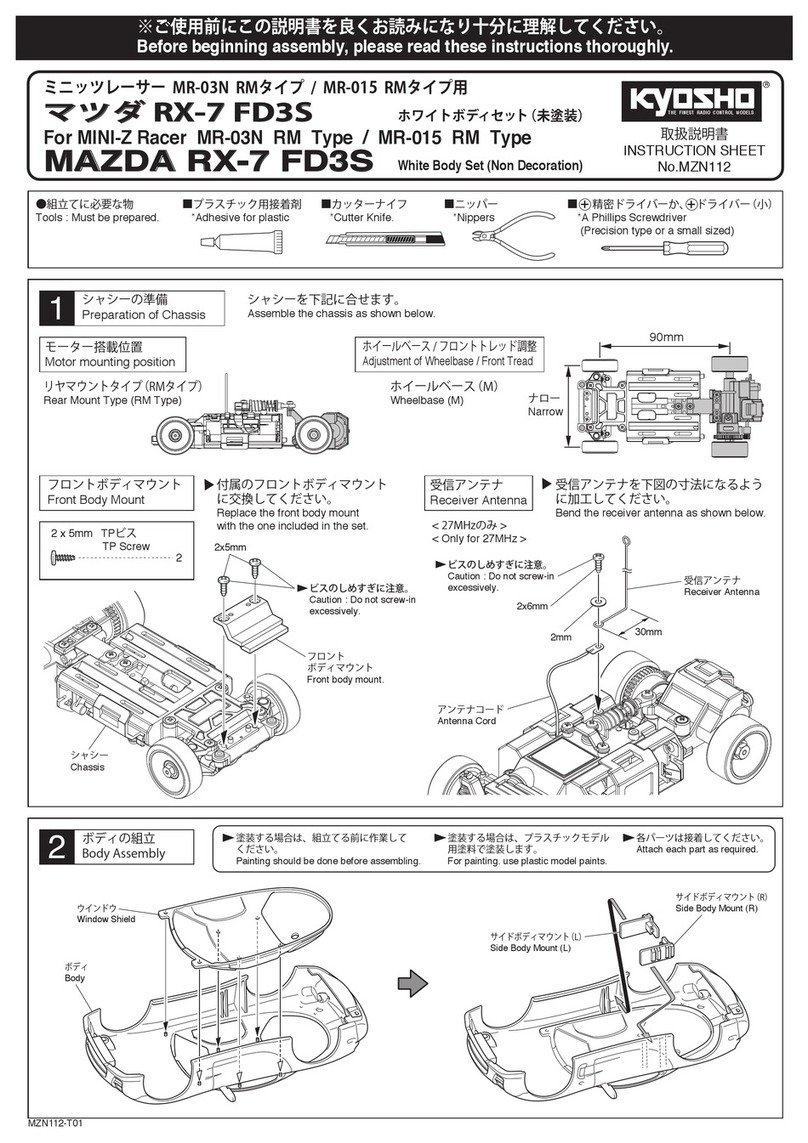

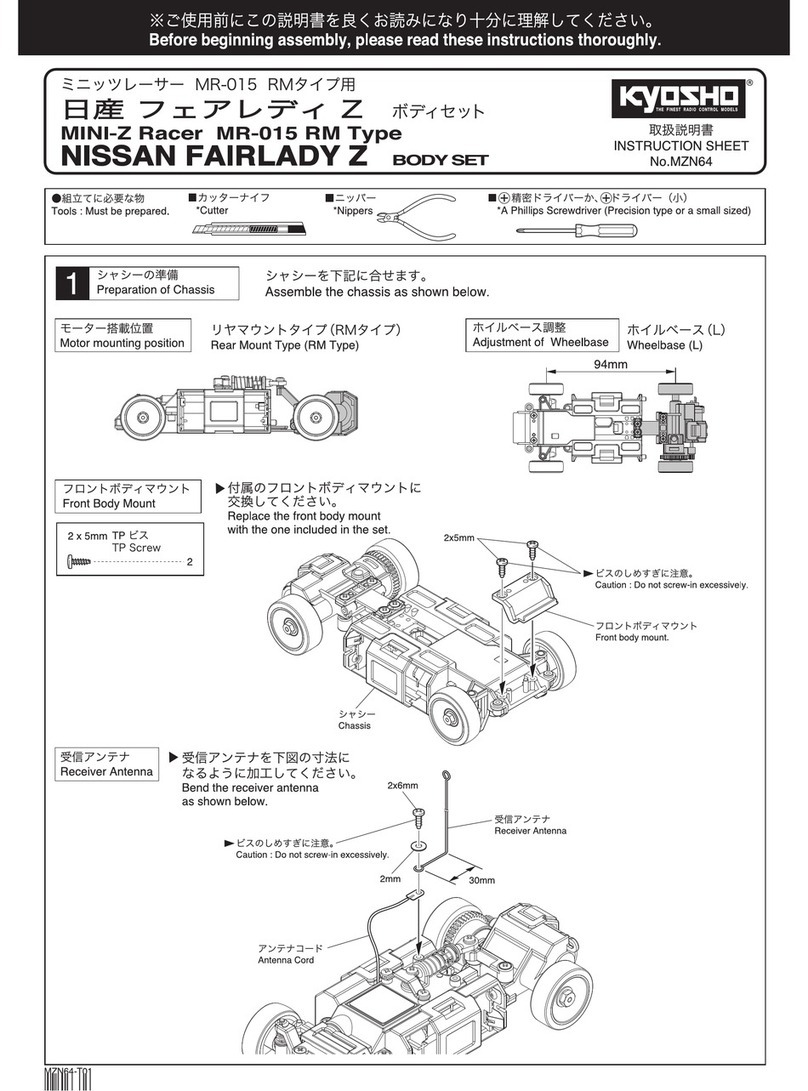

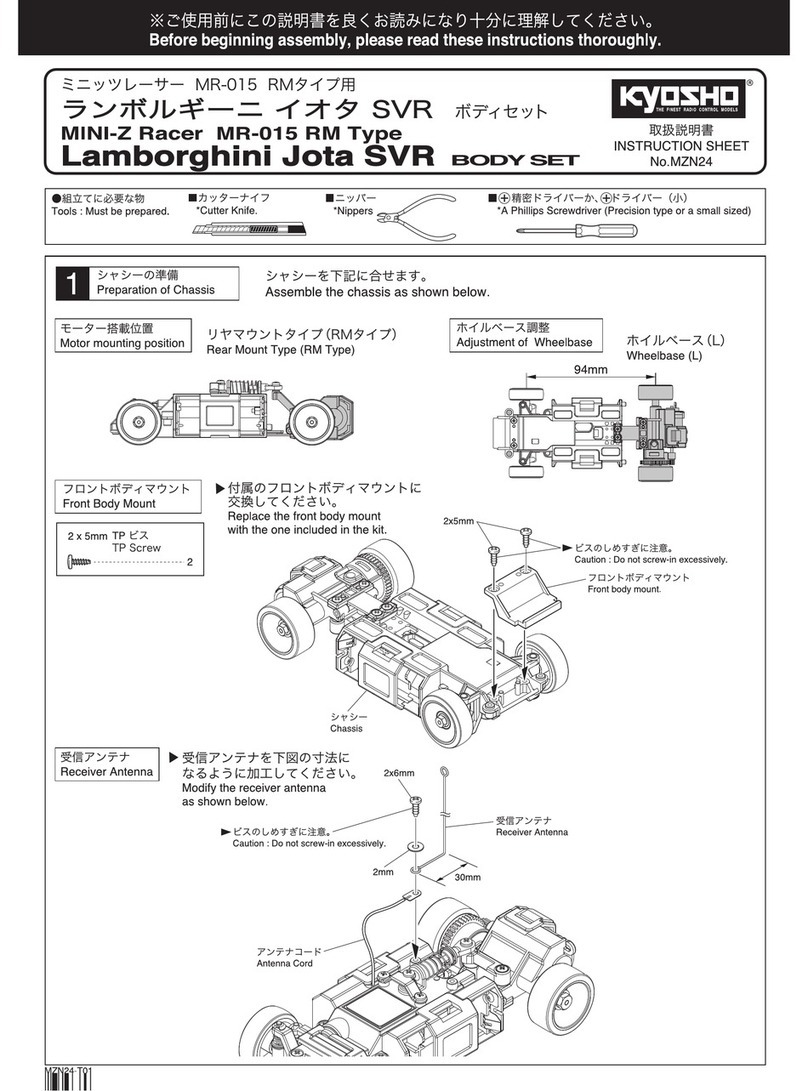

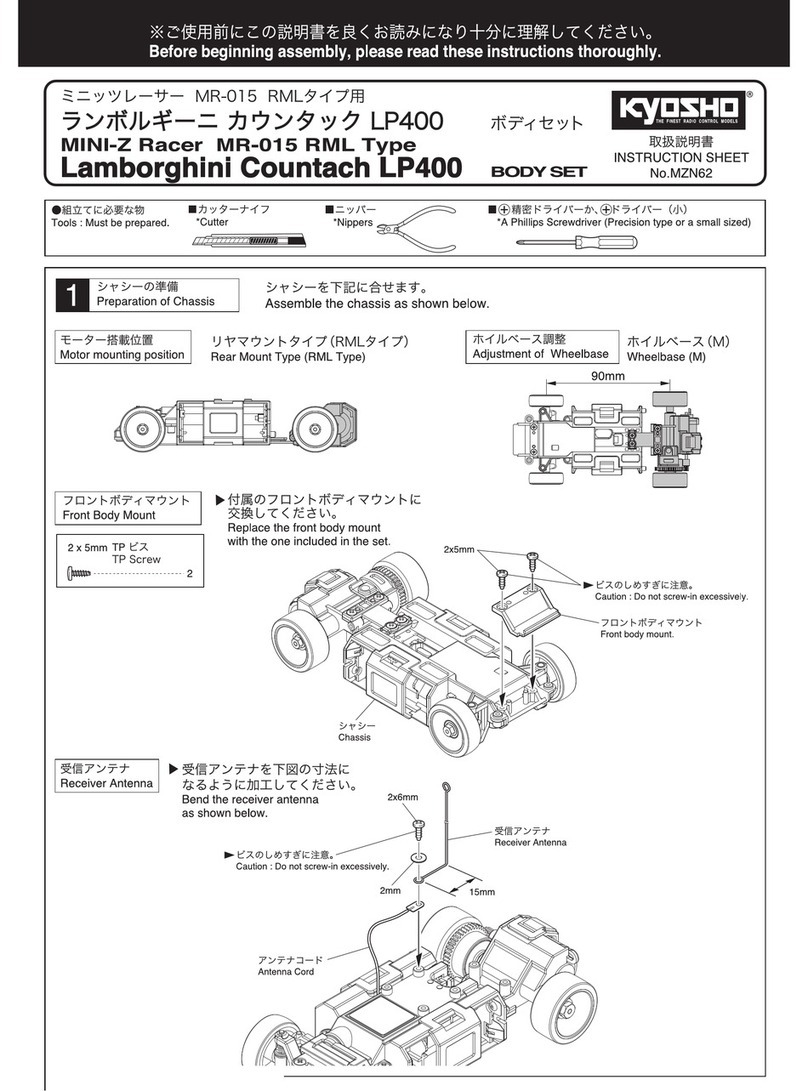

BEFORE

ASSEMBLY

ORead

the

instruction

carcfull)•.

You

can

assemble the

kit

more easily

if

you

have

grasped

the

general idea

or

steps

and

structure

beforehand by

reading it

through

to

the

end.

OCheck

the

parts

in

the

kit.

Instruct

ion

Check

to

see

if all

the

parts

are

correctly

bagged

as

they

are

listed

0

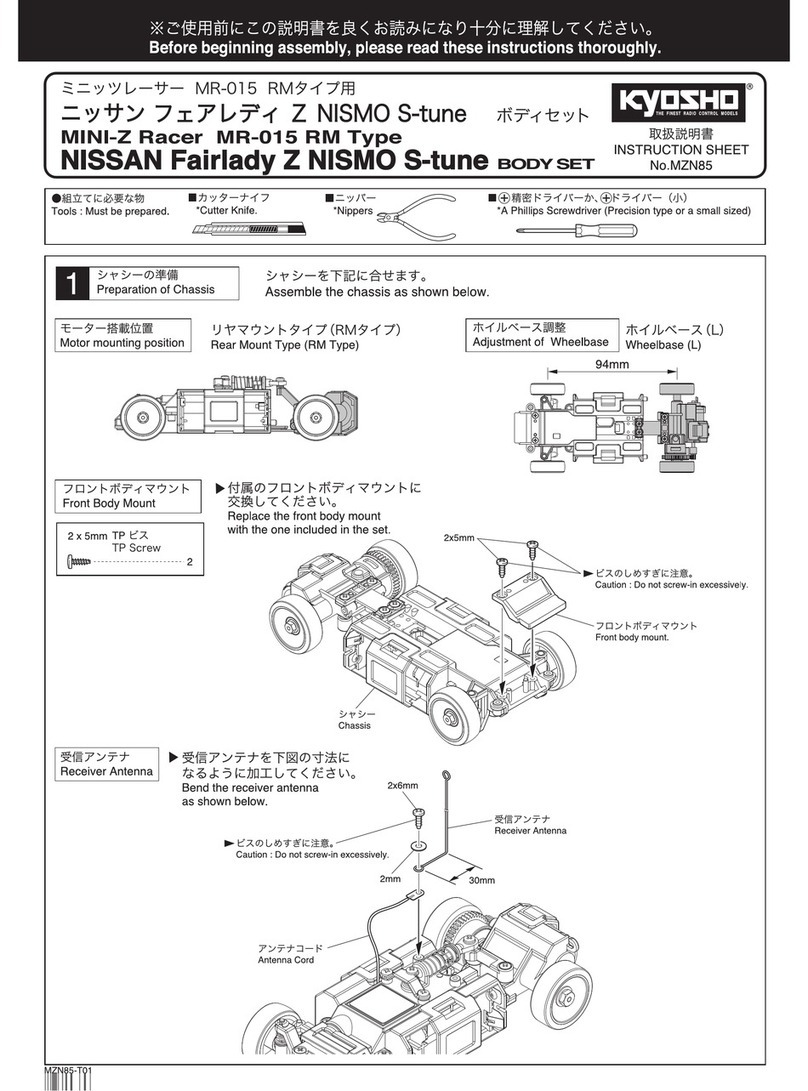

Be

well

aware

of

the

diHerent

types

or

screws.

The

difference between

the

TP

Screw (

short

form

of

self-tapping

screw)

and

the

ordinnrly

screw

is

.....

•

TP

Screw

ail!!!'!!:

ID

I Some

of

them pointed tips.

Coarser

Thread

• Ordinnrly

ScrewQ

'

Finer

Thread

=-..-

A hexagonal

•

Set

Screw

~

hollow in place

in the Bagged

Parts

List. Your

through

understanding

of

the

assembly

of

screw

head.

prior to

starting

will

enable you

to

build the

kit

without

am·

difficulty. •

OCheck

the

components in

the

kit

prior

to )'Our

startlngs

or

the assembly.

Any claims for replacements

or

refunds

f

or

the

model in the process

of

assembly will

not

accepted

without

shortage

or

in!criorit)'

or

the

pans.

0 Learn on the

marks

described in

the

instruction.

-g)

... Place

where

grease

should be applied.

c=

=-

0 Pick

up

the

correct

parts

and

screw.

Compare

the

shape

and

size

of

small

parts.

such

as

screws. nuts.

and

washers

with

the

actual

size

drawing

in

each

step

.

0

Be

sure

about

the

location

and

direction

or

parts

to

install.

Double-check

the

location

and

direction

or

?;

parts

with

the

illustraton

before installation.

When necessary. assemble

the

parts

themselves

tentatively before proceeding to

the

next

step.

0

no

not tighten

the

TP

Screw too

strong

...

'

Direction

. '

--

Do

not

usc excessive force

when

tightening

the

TP

Screws.

or

you

may

strip

the

thread

in

the

plastic. It is recommended to

stop

tightening

it

when

the

thread

part

on

the

screw

goc.

into

the

plastic

part

and

you reel someresistanee . .

from

the

tightening Q,•cr tighten may

stnp

the

·

thread

in

the

plastic.

(

It

will redu

ce

friction to

assure

smooth

movements. ) Steps

where

your

particular

attention

is required.

GOOD

TIIINGS NEED BESIDES TilE KIT

(2

Channel Radio System)

Transrniuer

(:\A

Size

Battery)

This model

is

designed for

BEC

syste

m radio only.

Usc a radio which

has

a

mark

shown

at

left.

Two

types

of

radio

control

set

arc

on

the

market.

the

stick type

and

the

steering wheel type,

Choose which ever you like.

Servo

f'or

Trans

mitter

.... 8 pes.

(1-11

-Cad

Battery)

This

model is designed to usc a rechargeable

7.2V

Sprint

Battery

SCR

and

7.2V Power

Battery.

1'\o.2310

7.2V Sprint

Battery

SCR

l':o.2306

7.2V Power

Battery

(Charger

lor

NI-Cad

Ballcry)

The

Kyosho's

l'i-Cad

Dauer)'

is high performance. If it is

charged

correctly.

it will

operate

for a considerable period.

Usc

one

of

the

chargers

listed below which

suits

your

need.

NO.

Name

2326 7.

2V

Power

Charger

1849 Multi

Charger

II

2246

f'ET Auto

Charger

0

·--·-·

Time

15

min.

l~ate

Features

7096

For

biginncrs

Built-

in

timer

20 min.

10096

Timer. Ammeter

built-

in

20 min.

10096

Trickle charging. Automatic

cut

-orr

at

peak

of

charge

(Tools Required) A Hex kC)', Grease

and

Cross Wrench

are

in

the

kit. Polyca Color Paint

:0.1icron

Line

Tape

Philips Screw Driver

(L

.M.S) Awl

--<====

==

• • 0

..

•

.....

cr:

! D

Screw Driver

(M)

C=t

§ J D

Sander

Sharp

llobb}

Knife Brush

Instant

Glue

lii

lliC:[I

JMC

=

::JIIJ

I

- 2