Targa Systems Division

S4 Ethernet NAS DTS Installation Guide 32003272-1 Rev 5

Table of Contents

1. Introduction..............................................................................................................1

1.1 Scope ...................................................................................................................1

1.2 Data Transfer System Overview..........................................................................1

1.3 Model Numbers....................................................................................................2

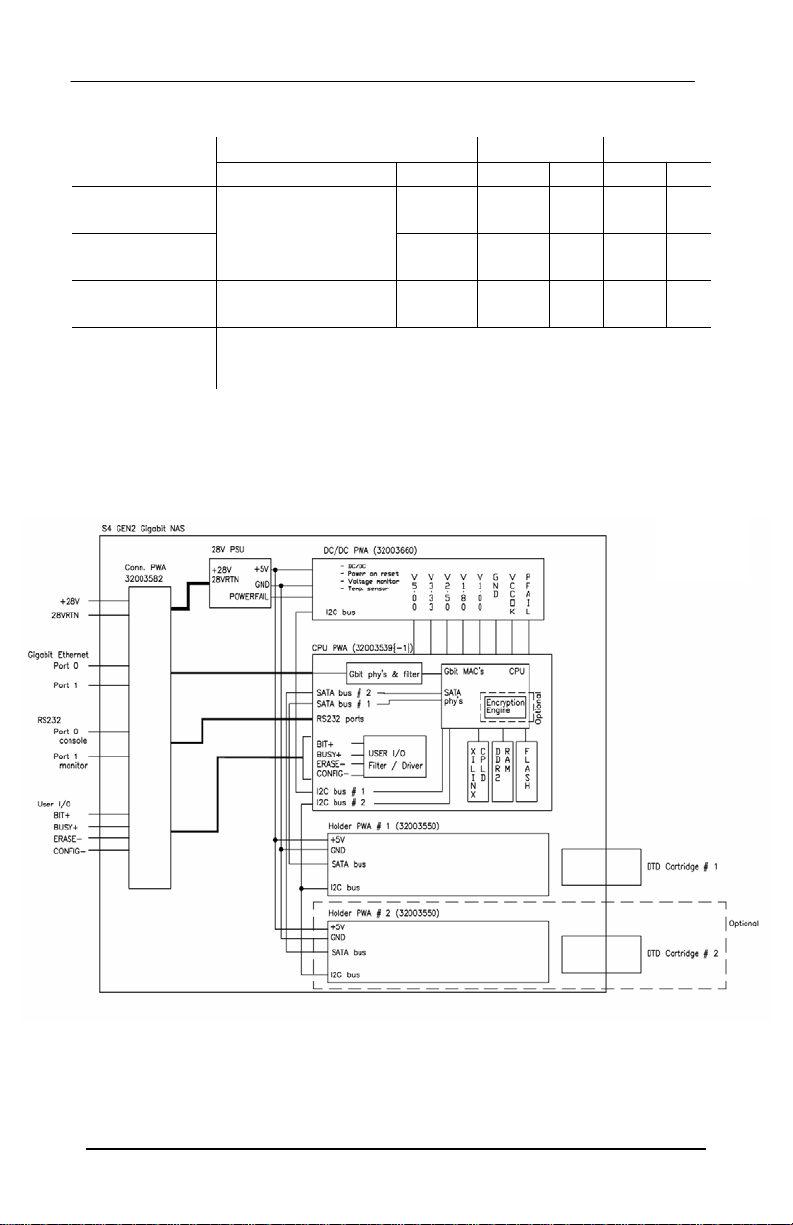

1.4 DTU Architecture..................................................................................................2

2. Specifications...........................................................................................................3

2.1 DTU and GSU Ethernet Interface........................................................................3

2.2 Data Transfer Unit................................................................................................3

2.3 Ground Station Unit .............................................................................................4

2.4 Data Transfer Device...........................................................................................4

2.5 Environmental Conditions....................................................................................5

2.5.1 Data Transfer Unit (DTU) and Data Transfer Device (DTD.........................5

2.5.2 Ground Station Unit (GSU)...........................................................................5

2.6 Interconnections...................................................................................................6

2.6.1 DTU J2 - Ethernet Connector Pinout..........................................................6

2.6.2 DTU J1 - Power & Auxiliary Signal Connector Pinout................................7

2.6.3 DTU and GSU - Auxiliary Input / Output Signal Functions.........................7

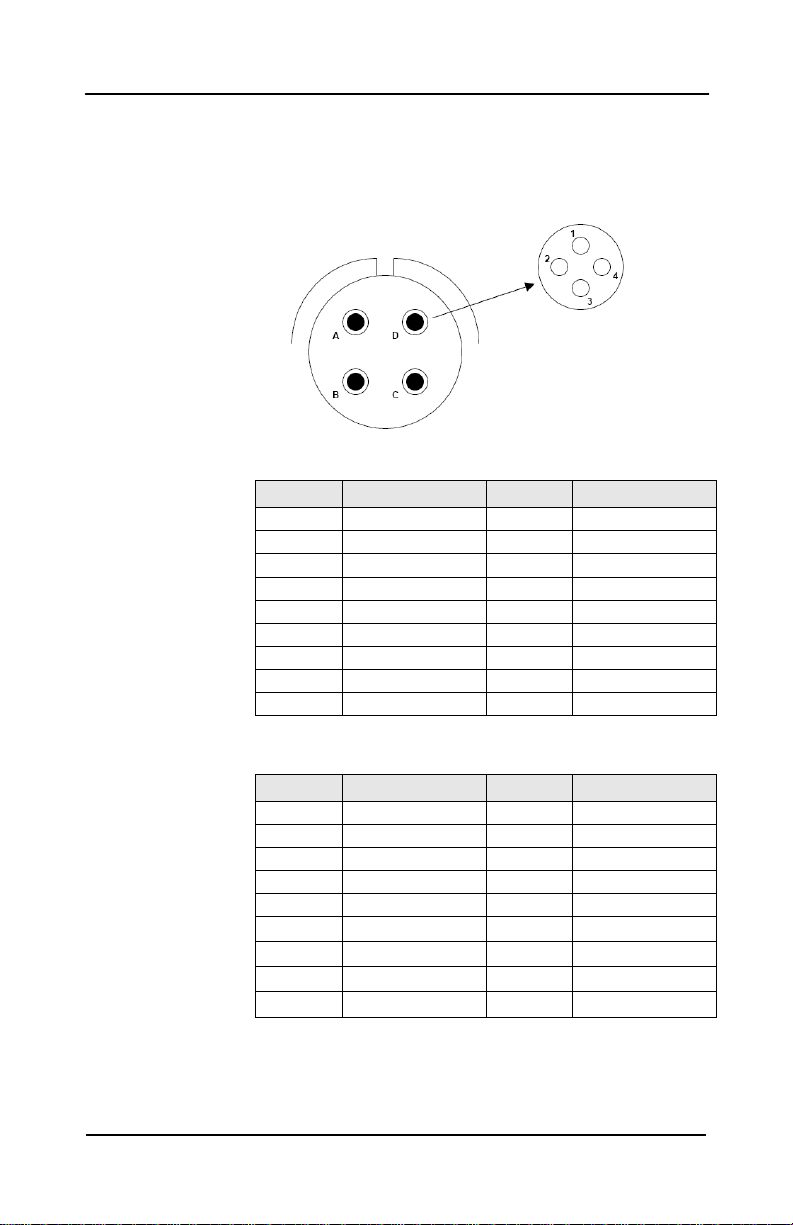

2.6.4 GSU Connector Pinout................................................................................8

2.6.5 DTD Connector Pinout.................................................................................9

2.7 Data Transfer System Reliability Performance...................................................9

2.8 Maintainability/Logistics Support.......................................................................10

3. Targa NAS DTU Operations – Overview ..............................................................10

3.1 DTD Use and Handling......................................................................................10

3.2Opening the DTD Access Door – DTD protection ............................................10

3.3 DTD NAS Partition File Structures ....................................................................11

3.4 DTD Write Protect..............................................................................................11

3.5 DTD Data Reliability...........................................................................................11

3.6 Power Fail ..........................................................................................................12

3.7 Security Erase....................................................................................................12

3.8 Monitoring DTU Output Messages....................................................................12

3.9 Dual DTD Data Transfer Unit ............................................................................12

4. Unit Configuration and Network Controls..............................................................13

4.1 User Configuration Utility...................................................................................13

4.1.1 DTU Configuration Control Panel ..............................................................13

4.1.2 Configuration Utility -Data Updates.........................................................13

4.2 DTU – Reboot Page...........................................................................................13

4.3 DTU-INFO Page.................................................................................................14

4.4 DTU Configuration Page....................................................................................15

4.5 DTU Network Configuration Page.....................................................................17

4.5.1 DTU Operation Mode.................................................................................18

4.5.2 Network Services........................................................................................19

4.5.3 Bridged Mode .............................................................................................22

4.6 DTU User Management Page...........................................................................23

4.7 DTD-INFO Page.................................................................................................24

4.7.1 Setup DTD Page.........................................................................................24

4.7.2 Setup Encryption Partition..........................................................................27

4.8 DTU Save and Restore......................................................................................27

5. Warranty & Repair.................................................................................................28

iii