ADJUSTING THE CONTROL SETTING

• After the power up routine is complete, the display will show the system water temperature.

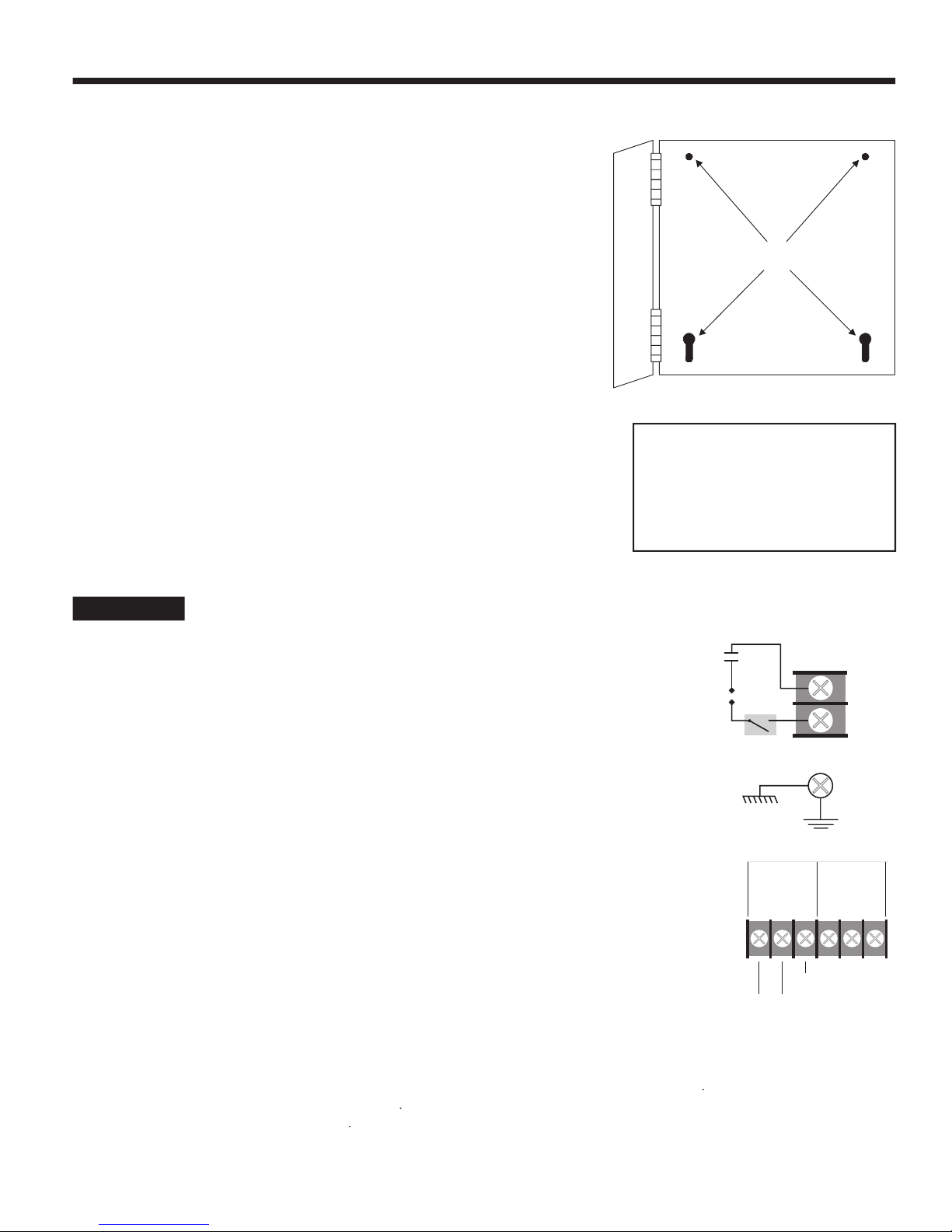

• To display the other control settings, repeatedly press the center

• A setting can only be adjusted when it is being displayed.

• Use the UP and DOWN buttons to adjust the setting.

• The display will always revert back to the actual system temperature after 30 seconds.

• Select the appropriate page from the list below for the available control settings for your

Set Point Control with Normal Sequencing Temperature or External Set Point pg. 10

Set Point Control with Oversize System Sequencing Temperature or External Set Point pg. 11

Outdoor Reset Control with Normal Sequencing pg. 12

Outdoor Reset Control with Oversize System Sequencing pg. 13

SET POINT CONTROL WITH NORMAL SEQUENCING

Dip Switch 8 - OFF

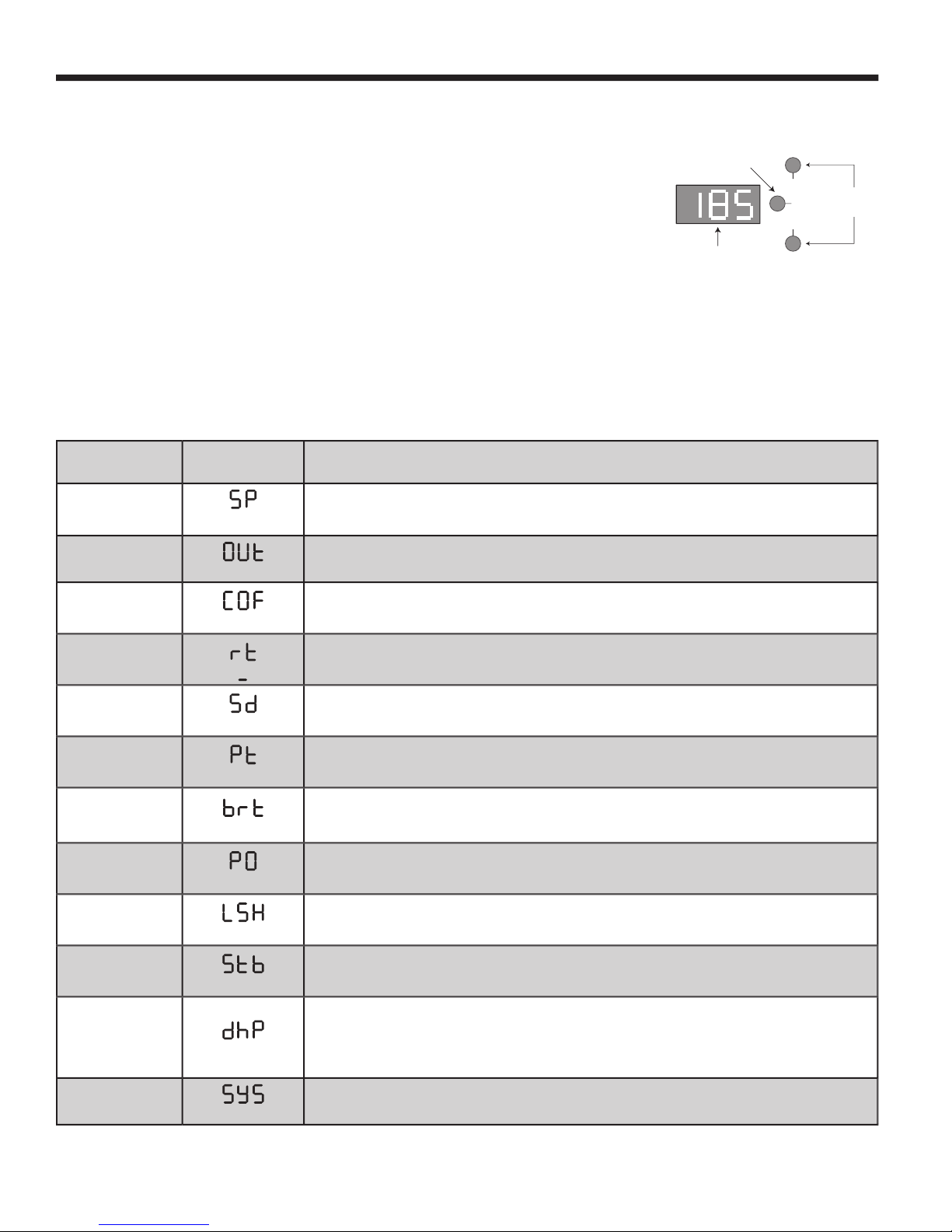

Press SELECT

Button DISPLAY Press and hold either the UP or DOWN button to adjust

Once

Set Point

The Set Point is the temperature which the SC will sequence stages to hold. Note that if you are

using the External Set Point, you will not be able to change the Set Point unless you adjust the 4-

20mA input. The Set Point is adjustable between -30°F to 250°F. Default is 70°F.

Twice♦

Outdoor Temp

This is the outdoor sensor temperature value.

3 Times♦♦

Outdoor Cutoff

Available only when the outdoor sensor is installed. When the outdoor temperature falls below the

Outdoor Cutoff value, the SC will activate stages for heat. The Outdoor Cutoff can be set ON or OFF

and from 40 to 100°F. Default is 60°F.

3 or 4 Times

Reaction Time

The Reaction Time controls the minimum run time for a stage (1/2 the Reaction Time). Also, it con-

trols how long should a stage run before it activates/subtracts another stage. It is adjustable from half

a minute (0.5) to 8.0 minutes. Default is 2 minutes.

4 or 5 Times

System Delay

The System Delay controls how long the System relay will remain energized after the last Output has

been turned off or the outdoor temperature rises above the Starter. The System Delay is adjustable

from 0 to 30 minutes. Default is 0.

5 or 6 Times

Purge Time

The Purge Time should be set to the length of the unit’s purge cycle. The Purge Time will apply

when any ON/OFF unit is activated. On multiple stage units, the Purge Time will only apply to the Lo

stages. The Purge Time is adjustable from 0.0 to 10.0 minutes. Default is 0.

6 or 7 Times

Boiler runtime

This is the minimum amount of time any boiler will run after the Purge cycle has been completed. This

timer does not apply when only one stage is running, the Last Stage Hold LSH applies in that case.

The Boiler Runtime is adjustable between 0 to 60 minutes. Default is 0.

7 or 8 Times♦♦

Program Offset

The Programmed Offset fi ne tunes the External Set Point. With a known 4mA input, the offset can be

set to make the External Set Point 110°F. The Program Offset is adjustable between -10°F to +10°F.

Default is 0°F.

7 or more Times

Last Stage Hold

To prevent short cycling of the last stage in low load conditions, the system temperature can exceed

the Set Point by the amount selected by the Last Stage Hold before the last stage is turned off. The

Last Stage Hold is adjustable between 0°F to 20°F. Default is 10°F.

8 or more Times♦♦

Setback

The Setback adjusts the number of degrees the Set Point water temperature will be reduced when

Input terminals 7 and 8 are closed. If the Setback is set to 0, then the system will Shutdown on a

closure. The Setback is adjustable from 0°F to 40°F. Default is 0°F.

8 or more Times♦♦

DHW Priority Time

Only available when the System Output is set to System Pump (dip switch 1 is ON and dip switch 6 is

OFF ) This setting adjusts the amount of time the System relay output will remain off during a DHW

call. If the DHW call is not satisfi ed before the DHW priority time has elapsed, the System relay will

energize to provide heat. The DHW Priority is adjustable from 0 to 4 hours in half hour increments.

Default is 0.

8 or more Times♦

Default

The SC returns to the default display of system water temperature.

♦ Actual temperature values are not adjustable

♦♦ May not be available, depending on status of the outdoor sensor and dip switches.

SELECT

SETTING

UP

DOWN

Press and

Hold to

Adjust

Press to Scroll

Through Control

Settings

Control Settings

Display