4 | MDG Operating & Maintenance Manual

SAFETY

Your safety and the safety of others

is a direct result of how you operate

and maintain your equipment. Read

and understand this manual and other

safety information provided with the

base machine and be sure that you

understand all controls and operating

instructions before attempting to operate this equipment.

Failure to follow the safety precautions can result in

personal injury, death or property damage.

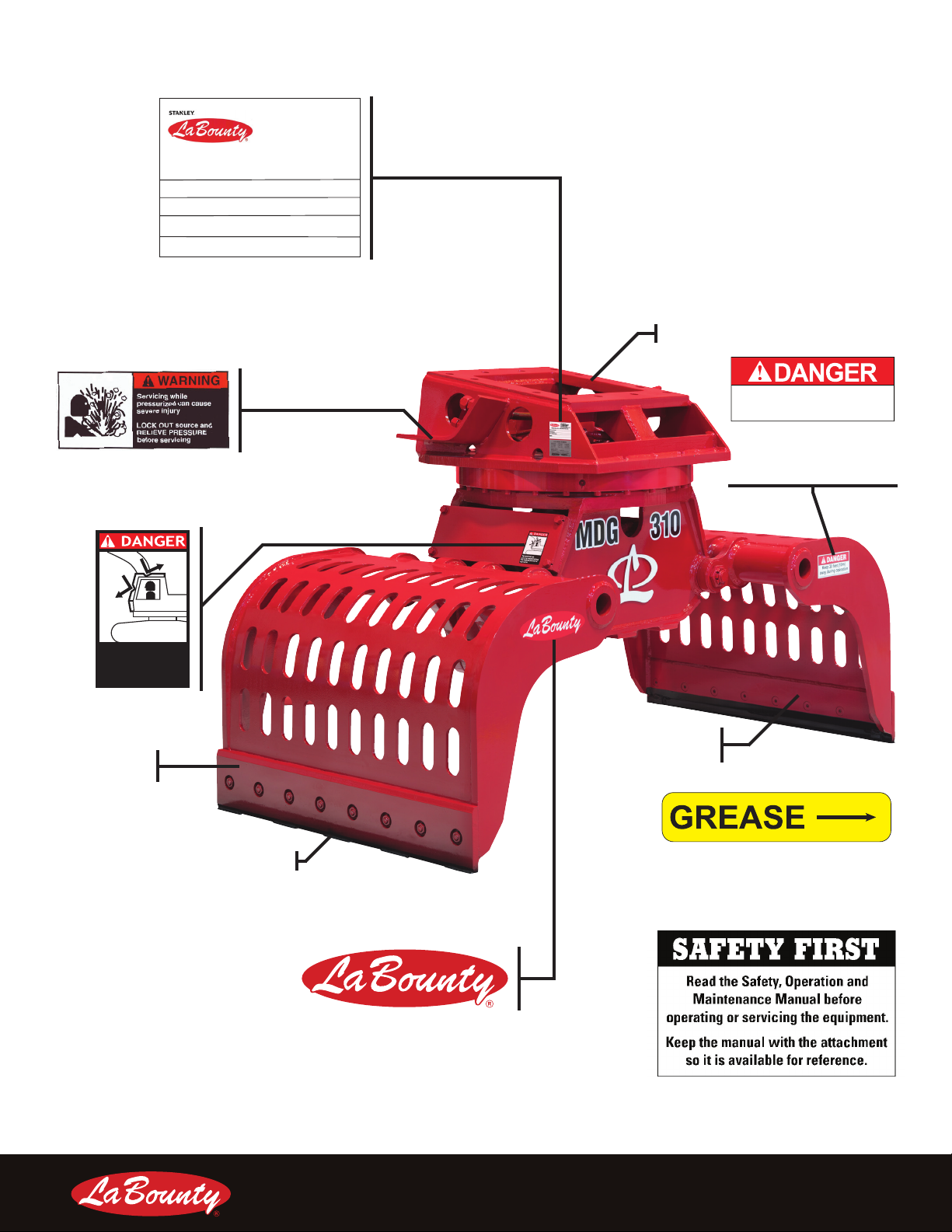

Carefully read all safety messages in this manual and on

your equipment safety decals to reduce the risk of injury.

Keep safety decals in good condition. Replace missing or

damaged safety decals. Failure to follow the warnings and

instructions may result in serious injury or damage to the

tool.

Because LaBounty cannot foresee all hazardous

circumstances, the precautions listed in this manual and

on the equipment are not all-inclusive. If a procedure,

method, tool or part is not specically recommended by

LaBounty, determine whether it is safe for you and others,

and that the equipment will not be damaged or made

unsafe as a result of your decision to implement it.

The basic rules are summarized in this section of the

manual. They also appear throughout the manual along

with additional specic rules for safety and operation.

• Wear personal protection equipment. This includes

eye protection, hard hat, steel toe shoes, gloves,

hearing protection and respirator.

• Use PPE that conforms to standards ANSI Z87.1 (Eye

and Face Protection), ANSI Z89.1 (Head Protection)

and ANSIZ41.1 (Foot Protection).

• If the attachment is not functioning properly, shut

down the machine, follow proper lockout / tag out

procedures and follow proper repair procedures.

• NEVER operate equipment without the original safety

guards in place.

• Ensure that the cab is equipped with the proper

safety guards for LaBounty applications. The cab

MUST be equipped with an approved Falling Object

Protection Structure (FOPS). The FOPS must

meet the requirements of SAE standard J1356. A

transparent, shatter-resistant shield covering the

front of the cab, is also required. Contact your base

machine equipment dealer or manufacturer for more

information on the availability of FOPS. Lack of proper

FOPS may result in injury or death.

• NEVER operate the excavator without a proper

restraint (seat belt) system in place. Doing so can

create loss of control or ejection from cab.

• NEVER operate the equipment while under the

inuence of drugs, alcohol or other substances that

inhibit mental abilities or reaction time.

• DO NOT process material with the attachment over

the operator’s cab. Doing so will result in severe

personal injury or death from falling debris.

• NEVER remove any pins unless the attachment is

on the ground and blocked up, or serious injury or

death could result. Metal chips or debris may y when

a connecting pin is struck. Use a brass drift when

striking pins and always wear protective clothing and

proper eye protection.

• Clear all persons and equipment from the area of

operation and machine movement. NEVER move

loads over people or equipment. When viewing the

operation of the attachment, maintain a safe distance

of at least 75 feet (23 meters).

• NEVER approach power lines with any part of the

machine. Keep clear at a minimum of 50 feet (16

meters).

• DO NOT close the attachment on a structure and

reverse the excavator in an attempt to pull down

material.

• Avoid tipping. The attachment will alter the lift

capacities of the base machine. DO NOT overload

the excavator or serious injury could result. Lift

capacities will vary if the base machine is not on level

ground. Lifting incorrectly can cause severe injury or

machine damage. Use the recommended excavator

counterweight. Use short slings and lift the load only

as high as necessary.