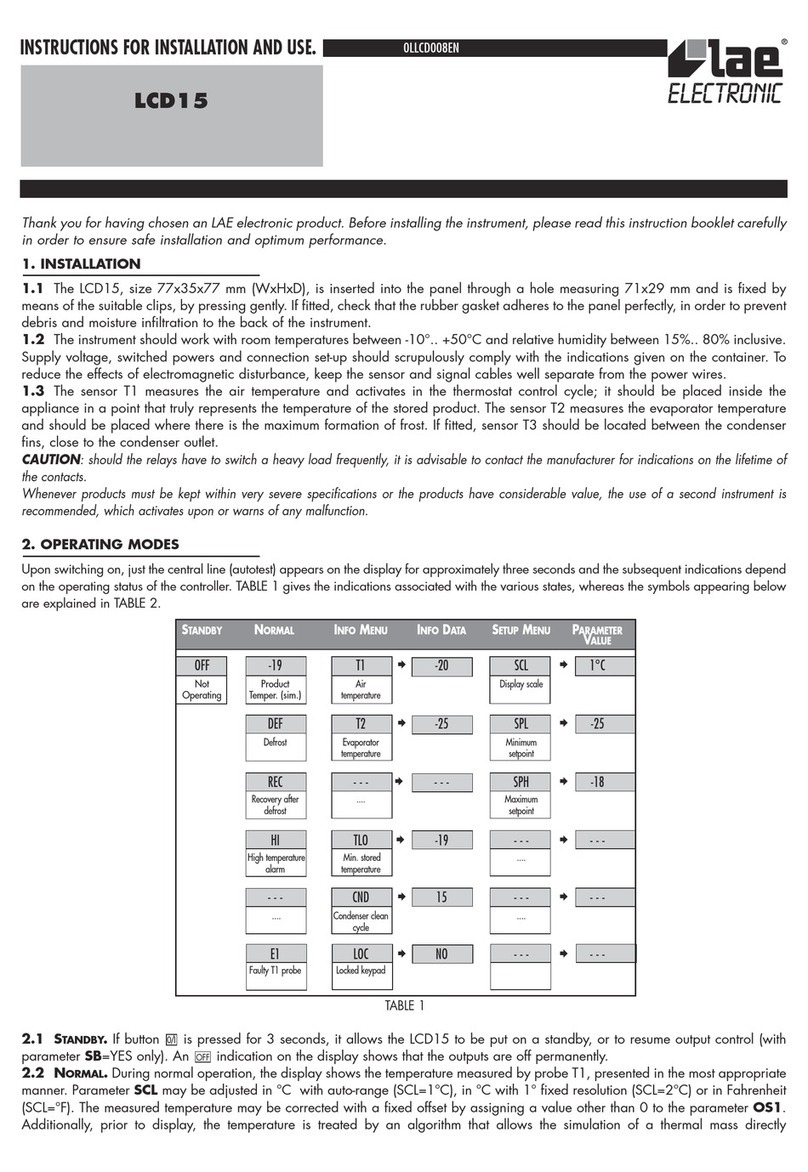

(SCL=2°C) or in Fahrenheit (SCL=°F). The measured temperature may be corrected with a fixed offset by assigning a value other than

0 to the parameter OS1. Furthermore, prior to display, the temperature is treated by an algorithm that allows the simulation of a thermal

mass directly proportional to the SIM value. The result is a reduction in the fluctuation of the displayed value.

The status of the compressor and auxiliary outputs is shown through the respective dots on the display.

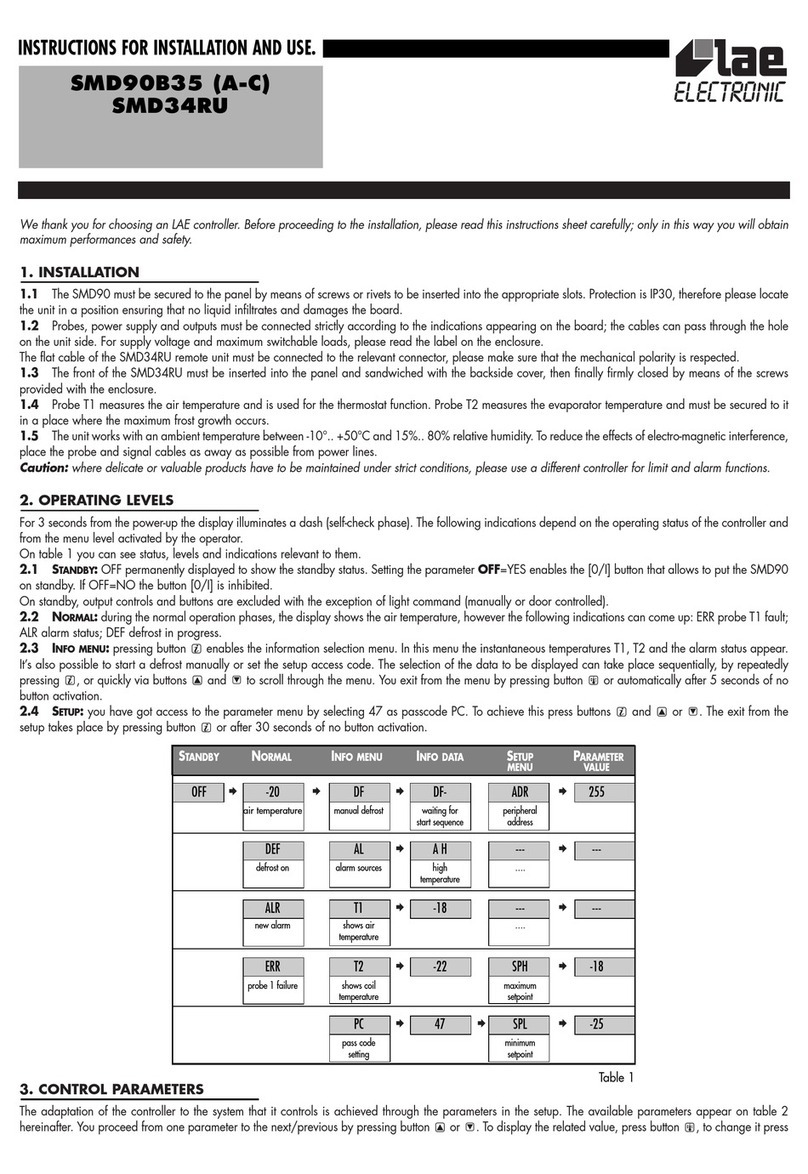

TABLE 2

CAUTION: upon changing the display scale SCL, it is ABSOLUTELYnecessary to reconfigure the parameters related to the absolute (SPL, SPH,

SP) and differential (HYS, ATL, ATH, OS1) temperatures.

4. THERMOSTAT CONTROL

4.1 Thermostat control is based on comparing the temperature T1, the set point SP and the hysteresis HYS.

Example: SP= 2.0; HYS= 1.5, relay Off with T1= +2.0° and On with T1= +3.5°.

The compressor only switches On again if the minimum Off time CRT since the previous switchover has elapsed. Whenever a very

small hysteresis HYS must be maintained, we advise assigning a suitable value to CRT in order to reduce the number of starts/hour.

4.2 If sensor T1 fails, the output is controlled for a fixed time established with CDC; this determines the activation time of the output

within 10-minute cycles.

Example: CDC=06, 6 minutes On, 4 minutes Off.

5. DEFROSTING

Defrosting starts automatically when the internal timer reaches the necessary time to obtain the defrosting frequency set with DFR. For

example, with DFR=4 defrosting occurs once every 6 hours. With DFR=0 the timed defrosting function is cut out. When the controller

is put on a standby, the timer count is frozen.

Defrosting may also be induced manually by pressing the buttons and simultaneously.

The internal timer is set to zero when the instrument is switched on, at each subsequent defrost start and, if in the standby mode,

whenever standby lasts for at least the time set in DTO.

Defrosting occurs upon stopping the compressor and, if OUA=DEF, upon activating the defrost heater through the auxiliary relay for

the time DTO. During defrosting appears on the display and remains there after the end of defrosting for the time set in DDY.

6. ALARMS

With LDU15 correct operation of the thermostat, sensor and the periodic warning of condenser cleaning can be checked. The alarm

warnings are given on the display with explicit indications (table 2) and, with OAU=ALR, also on the auxiliary relay (not for condenser

cleaning).

The alarm warning is removed from the display upon pressing any button for two seconds, but if the alarm persists, it reappears after

30 minutes. Operation of the various sections is given in detail below.

6.1 The parameters ATL and ATH define two differential temperatures that, referred to the set point, determine the temperature alarm

thresholds. ATL establishes the alarm differential for temperatures below set point, ATH the alarm differential for temperatures above

set point + hysteresis. Putting one or both differentials to 0 cuts out the corresponding alarm.

Example: SP= 2.0, HYS= 1.5, ATL= -5.0, ATH= 5.0; the alarm thresholds are fixed at -3.0° and +8.5°.

The alarm warning may be immediate or delayed by the time ATD whenever this is greater than 0. The high temperature alarm is

bypassed during defrosting.

6.2 Assigning a value greater than 0 to the parameter ACC enables the indication for periodic cleaning of the condenser. In other

words, when the count of compressor hours of operation reaches the equivalent in weeks set with ACC, an indication for cleaning

appears on the display (see table 2).

Example: with ACC=16 there is a warning once every 16x7(weeks)x24(hours)=2688 hours of compressor operation, in other words,

assuming for this an operation with 5 minutes On and 5 minutes Off - after approx. 32 weeks.

The time counter may only be cleared after the programmed time has been reached. Therefore proceed as follows: press the buttons

and in sequence and hold them simultaneously.

7. AUXILIARY FUNCTIONS

The LDU15 controller comprises a button and an auxiliaries relay with functions that may be suitably combined through the parameters

OAU and BAU. The parameter OAU assigns one of the following functions to the auxiliary output: alarm warning (ALR), defrost heater

control (DEF), manual control (MAN), auxiliary loads (SBY), cut-out (NON). The parameter BAU determines the function associated