minute steps.

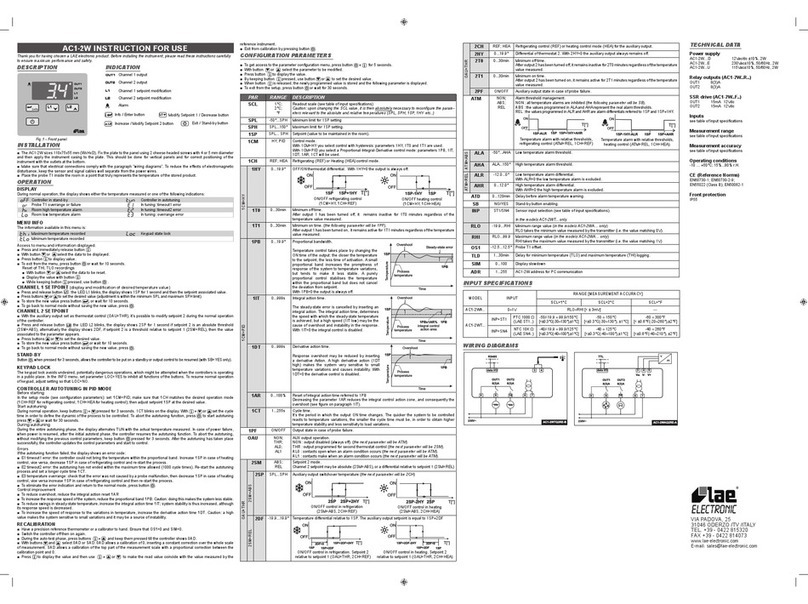

In Figure 1 some examples of the possible combinations appear.

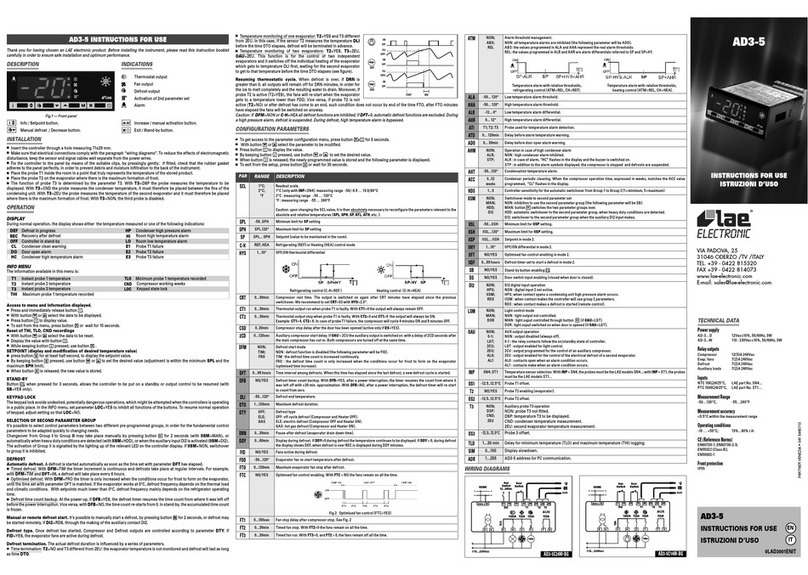

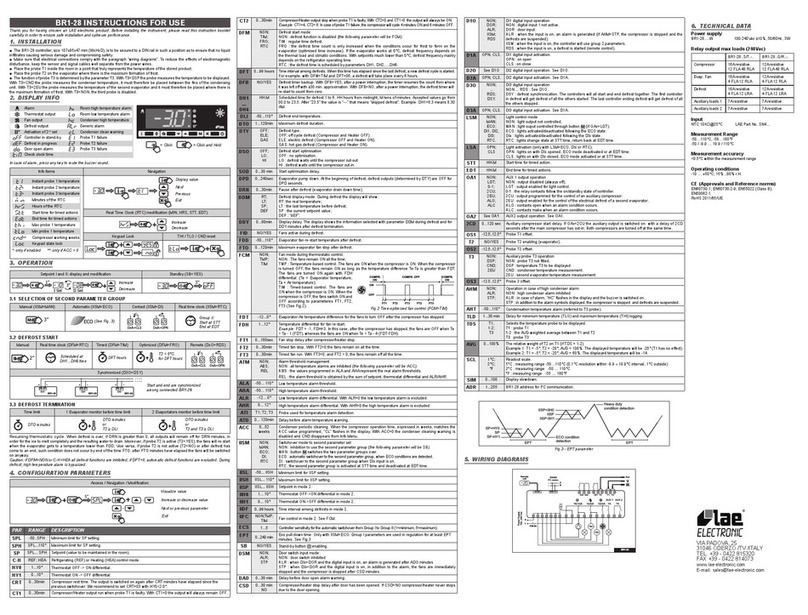

3. DISPLAYS

3.1 At power-up, the BIT12 shows “--“ for 4 seconds during which it performs self-check; then, the temperature measured (TA+to) appears.

By means of parameter tS it's possible to reduce the display fluctuations by simulating the behaviour of product core temperature. The

slowdown is proportionated to tS parameter value.

3.2 Under some circumstances, owing to the structure of the cabinet or air circulation, the displayed temperature does not match the most

representative product temperature. In this case, through the parameter to, temperature TA may be offset to obtain the desired readout.

3.3 To display the instantaneous temperatures TA and TE press keys or respectively.

3.4 By means of key it’s possible to display the current setpoint value both when the unit operates in MEMORY and SELECTORS(1) mode.

In this latter case, an attempt to modify the setpoint will cause the display to show “Lo” to warn you that setting is locked.

3.5 If parameter th is given a value greater than 0, “dF” is displayed all through defrost and after until its programmed value in minutes is

over.

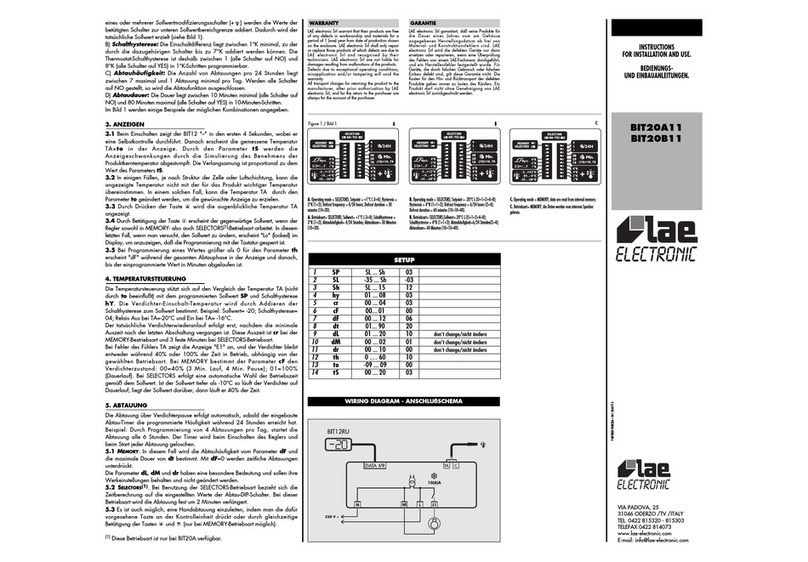

4. TEMPERATURE CONTROL

Temperature control is based on the comparison between temperature TA (not affected by to), the programmed setpoint SP and the hysteresis

hY. The refrigerator off switching temperature is determined by setpoint plus differential. Ex.: setpoint= -20; hysteresis=04, relay off with

TA= -20°C and on with TA= -16°C.

The actual compressor cut-in is only possible if the minimum off time has elapsed since the last cutout. This off time is cr in MEMORY mode

and is fixed to 3 minutes in SELECTORS mode(1).

If probe TA fails, the display shows “E1” and the compressor remains on for either 40% or 100% of the time, depending on the operating

mode selected. In MEMORY mode, parameter cF determines the compressor status: 00=40% (3min. on, 4min. off); 01=100% (always on).

In SELECTORS mode, selection takes place automatically according to the actual setpoint. Therefore, for setpoints lower than -10°C, the

compressor is always on, differently it works at 40%.

5. DEFROST

Defrost takes place automatically when the built-in timer matches the time needed to obtain the selected defrost spread over 24 hours. For ex.:

by setting 4 defrosts per day, defrost will be started every 6 hours. This timer is cleared when the unit is powered up and every time defrost

starts.

5.1 M

EMORY

.In this case defrost frequency is determined by parameter dF and the maximum duration by dt. When probe TE placed on the

evaporator measures temperature dL before the limit time dt has elapsed, then defrost is terminated in advance. During defrost the outputs

switch on or off depending on the defrost mode selected via parameter dM: 00=off cycle, 01=electrical, 02=hot gas.

With dF=0, timed defrosts are suspended.

With dr you can add a pause, between defrost and compressor re-start, allowing a homogeneous heat spread all over the evaporator and,

at the same time, the drain of the water formed from ice melting.

Probe TE is only active in the MEMORY mode. In the event of probe TE failure, "E2" is displayed.

5.2 S

ELECTORS

(1).When SELECTORS mode is on, timer count refers to the values set via the defrost switches, it doesn't keep into consideration

the temperature measured by the evaporator probe TE. Therefore defrost termination occurs when only the maximum time is achieved. In this

case, you can obtain an electrical or off cycle defrost, depending on the connected load and the drain time is fixed to 2 minutes.

5.3 Defrost may also be induced manually, by pressing the button located on the control unit or by pressing keys and simultaneously

(in mode MEMORY only).

Thanks to the normally closed contact of the defrost relay it's possible to stop the evaporator fans during defrost.

(1) This operating mode is available in the BIT20A only.

WARRANTY

LAE electronic Srl warrant that their products are free of any defects in workmanship and materials for a period of 1 (one) year from date of production

shown on the enclosure. LAE electronic Srl shall only repair or replace those products of which defects are due to LAE electronic Srl and recognised by their

technicians. LAE electronic Srl are not liable for damages resulting from malfunctions of the products.

Defects due to exceptional operating conditions, misapplication and/or tampering will void the warranty.

All transport charges for returning the product to the manufacturer, after prior authorisation by LAE electronic Srl, and for the return to the purchaser are

always for the account of the purchaser.

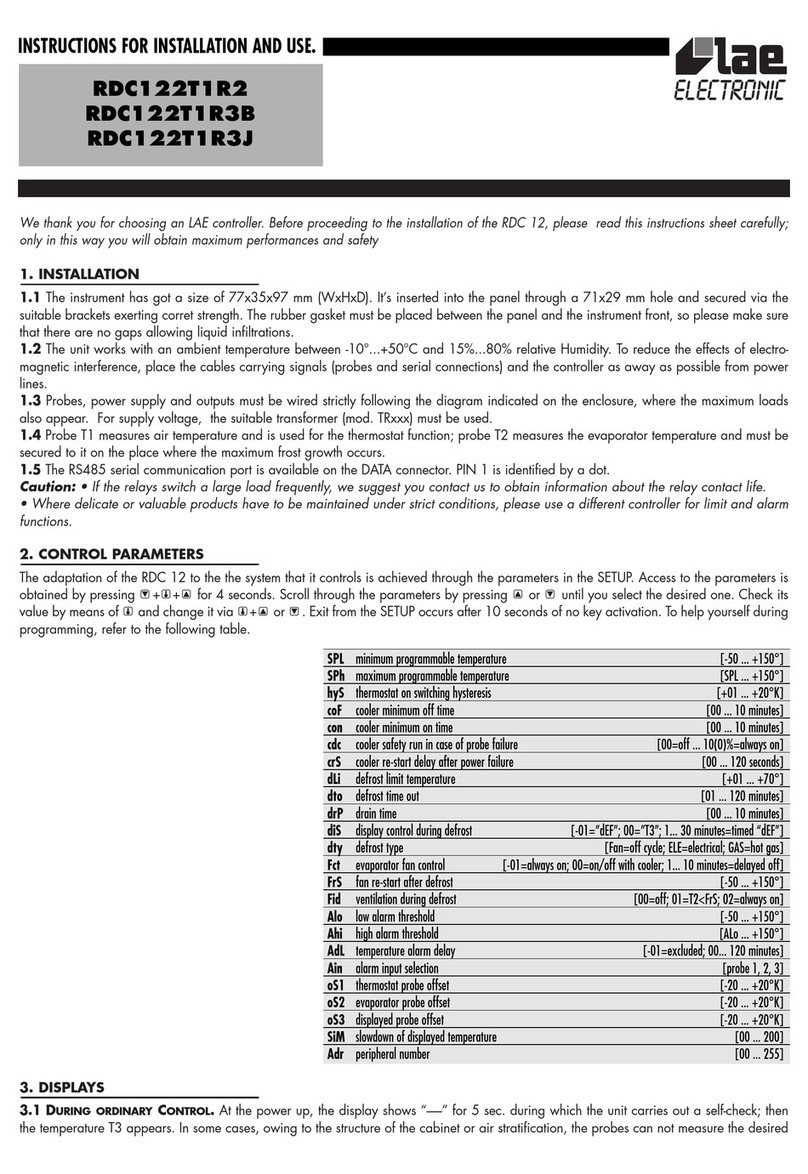

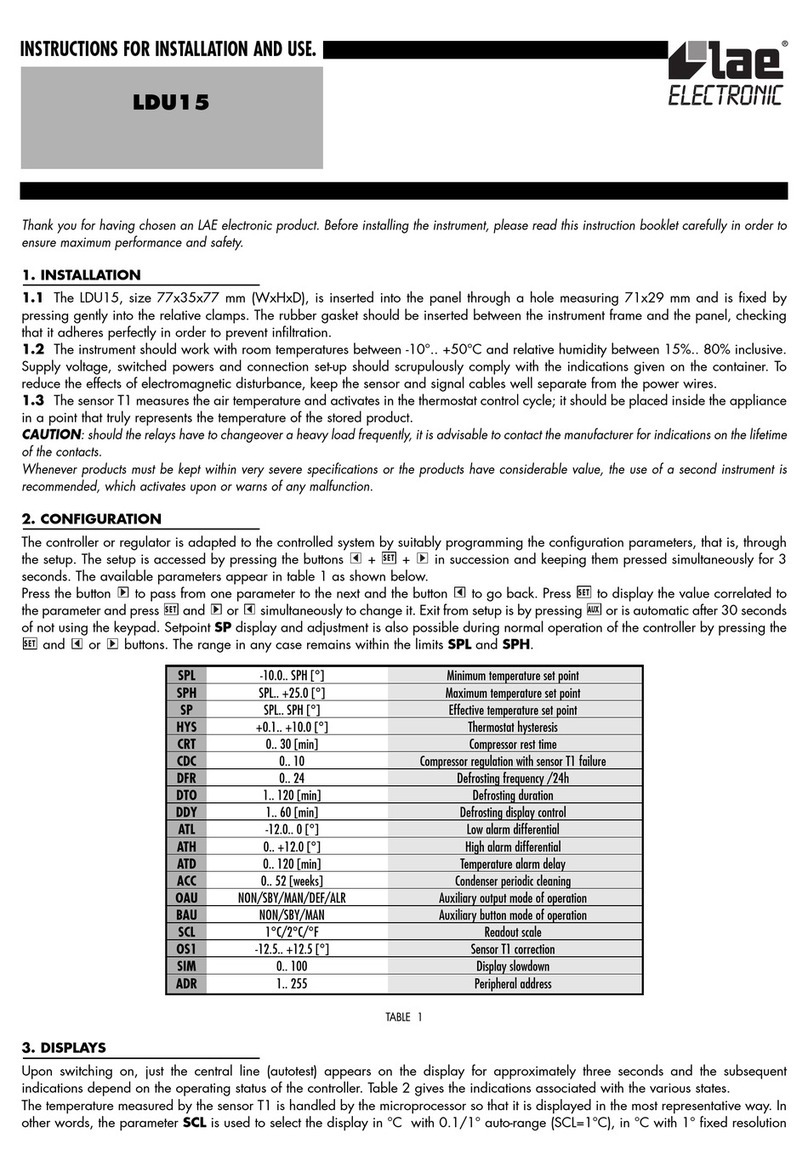

INSTRUCTIONS FOR INSTALLATION AND USE.