The defrost relay status is signalled by illuminating the relevant dot on the display.

7. EVAPORATOR FAN CONTROL

7.1 During temperature control, the fans are controlled by FRC. If FRC=0 the fans run continuously, if it’s greater than 0, then the fans cycle according to the

compressor. Both are switched on simultaneously but the fan run continues for a time proportionate to the compressor run and the FRC parameter. One unit of

FRC corresponds to 20% of the compressor run. For instance, with FRC=2 compressor and fans start simultaneously and, if the compressor runs for 6 minutes,

then the fans are on for 6+2 minutes and 24 seconds (40% of 6 minutes).

7.2 If the SMD is connected to a door switch, you must set the parameter DS to YES to obtain an evaporator fan control according to door opening. This

control takes place during temperature control only.

7.3 After defrost, if probe T2 is active (T2=YES) temperature FDR provides fan re-start. In other words, the fans re-start when the evaporator has a temperature

lower than FDR. If this condition is not met within 3 minutes following defrost termination, the fans will however re-start.

The relay status is signalled by the relevant dot on the display.

8. ALARMS

The SMD90 allows a check on the correct operation of the thermostat, on the door being left open and on the periodic condenser clean warning, in addition

to the functional alarms because of power failure and fault of probes T1 or T2. When an alarm takes place, the controller switches on the relevant relay and

buzzer, shows the anomaly by flashing the relevant LED and ALR on the display. Hereinafter we report how the unit works according to the alarm sources.

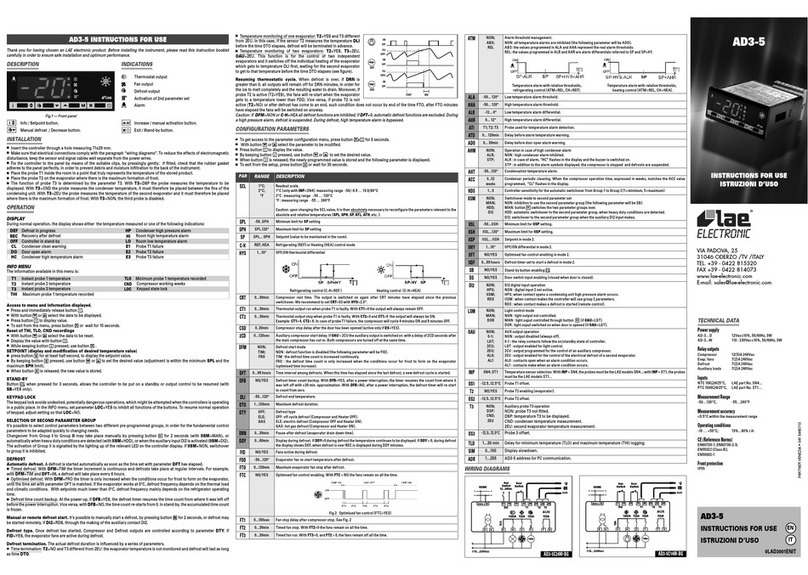

8.1 ATL determines the alarm differential for temperatures lower than setpoint (cooling) or setpoint + hysteresis (heating) and ATH is the alarm differential for

temperatures higher than setpoint (heating) or setpoint + hysteresis (cooling).

Example 1: SP= -20, HYS= 02, ATL= -05, ATH= 05;

the alarm thresholds are set to –25° and –13°.

Example 2: SP= 70, HYS= -04, ATL= -05, ATH= 05;

the alarm thresholds are set to +61° and +75°.

The temperature alarm warning can be immediate or delayed by the time ATD if it’s greater than 0. By setting to 0 one or both differentials, the corresponding

alarm is excluded.

During defrost, the high temperature alarm is excluded.

8.2 By enabling door switch control, DS=YES, the relevant door alarm function is also enabled. Therefore, as described in 7.2, when the door is opened the

fans will be stopped immediately and, after the delay ADD, the compressor will be stopped too and the alarm will be signalled.

8.3 By setting parameter ACL to a value greater than 0 you enable the periodic condenser clean warning. This means that, when the timer counting the

thermostat running time matches the weeks programmed with ACL, the display will show a condenser clean request.

Example: with ACL=16 you will obtain a warning every 16x7x24=2688 hours of compressor operation. In other words supposing that the compressor

runs 5 minutes and rests for 5 minutes, there will be a warning after about 32 weeks.

To reset the timer, enter info menu and get to the display of the indication related to the condenser clean - A C – then press buttons and simultaneously.

8.4 In case of a new alarm, pressing button removes the indication ALR permanently, mutes the buzzer and by pressing button again shows the alarm

cause. The indications on the display are:

A H high temperature; A L low temperature; A D opened door; A C condenser clean; A 1 probe T1 fault; A 2 probe T2 fault; A – no alarm.

By pressing button , the buzzer is muted, after that, if the alarm persists, it’s periodically switched on for 20 seconds every hour until the alarm is over. This

applies to all alarms with the exception of the condenser clean warning.

The alarm LED and relay, on the contrary, remain on as long as the alarm persists.

9. LIGHT SWITCH AND SERIAL COMMUNICATION

9.1 The relay controlling the lights can alternatively be controlled manually by means of button or, if the switch is fitted, automatically when the door is

opened. In this case the parameters DS and LDC must both be set to YES. As described at 2.1 the light function is independent from standby.

9.2 The SMD90 can be fitted with RS485 serial port allowing the controller to exchange information with supervisory softwares like the TAB. The data base

puts all measurement and control data of the controller on line. The identification of every single unit within the network is given by parameter ADR.

WARRANTY

LAE electronic Srl warrant that their products are free of any defects in workmanship and materials for a period of 1 (one) year from date of production

shown on the enclosure. LAE electronic Srl shall only repair or replace those products of which defects are due to LAE electronic Srl and recognised by their

technicians. LAE electronic Srl are not liable for damages resulting from malfunctions of the products.

Defects due to exceptional operating conditions, misapplication and/or tampering will void the warranty.

All transport charges for returning the product to the manufacturer, after prior authorisation by LAE electronic Srl, and for the return to the purchaser are

always for the account of the purchaser.

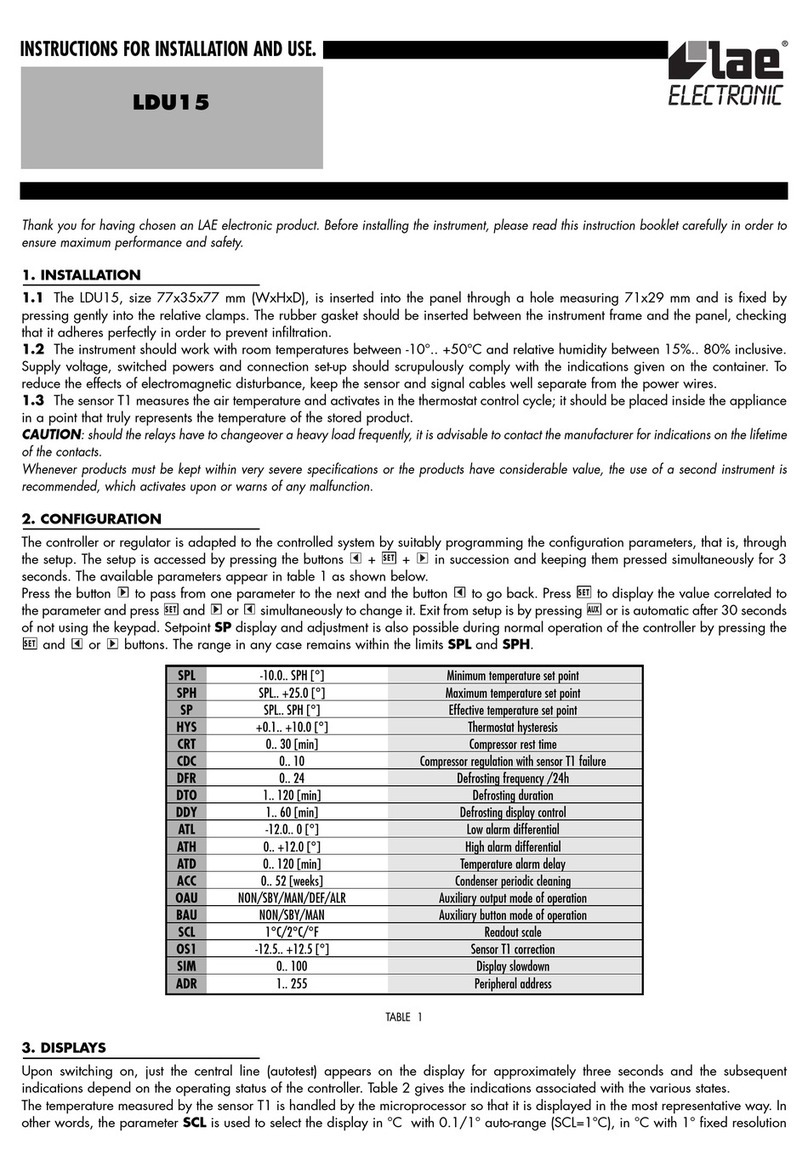

INSTRUCTIONS FOR INSTALLATION AND USE.