(g)

U liser la vitesse la plus lente au démarrage d'une

nouvelle pièce.

RÈGLESDEL'OPÉRATEUR

1.

CONSERVEZ TOUS LES DISPOSITIFS DE

PROTECTION EN PLACE et enbon état de fonc

onnement.

2.

ENLEVEZ LES CLÉS ET OUTILS. Prenez l'habitude

de vérifier si les clés et autres ou ls ne sont pas trop

près de la machine avant de la démarrer.

3.

CONSERVEZ LA SURFACE DE TRAVAIL PROPRE

ET LIBRE D'ENTRAVES. Les endroits encombrés

augmentent le risque d'accident.

4.

NE PAS UTILISER DANS LES ENVIRONNEMENTS

DANGEREUX. N' lisez pas d'ou ls électriques dans

les endroits humides, détrempés, ou sous la pluie.

Conservez l'espace de travail bien éclairé.

5.

TENEZ LES ENFANTS À L'ÉCART. Tous les visiteurs

doivent être tenus à une distance sécuritaire de l'aire

de travail.

6.

RENDEZ L'ATELIER À L'ÉPREUVE DES ENFANTS

avec des verrous, des interrupteurs principaux ou en

enlevant les clés de démarrage sur les

7.

NE FORCEZ PAS L'OUTIL. L'ou l effectuera un

meilleur travail et de façon sécuritaire s'il est u lisé

au rythme pour lequel il a été conçu.

8.

UTILISEZ L'OUTIL APPROPRIÉ. Neforcezpasunou

l ou un accessoire pour effectuer un travail pour

lequel il n'a pas été conçu.

9.

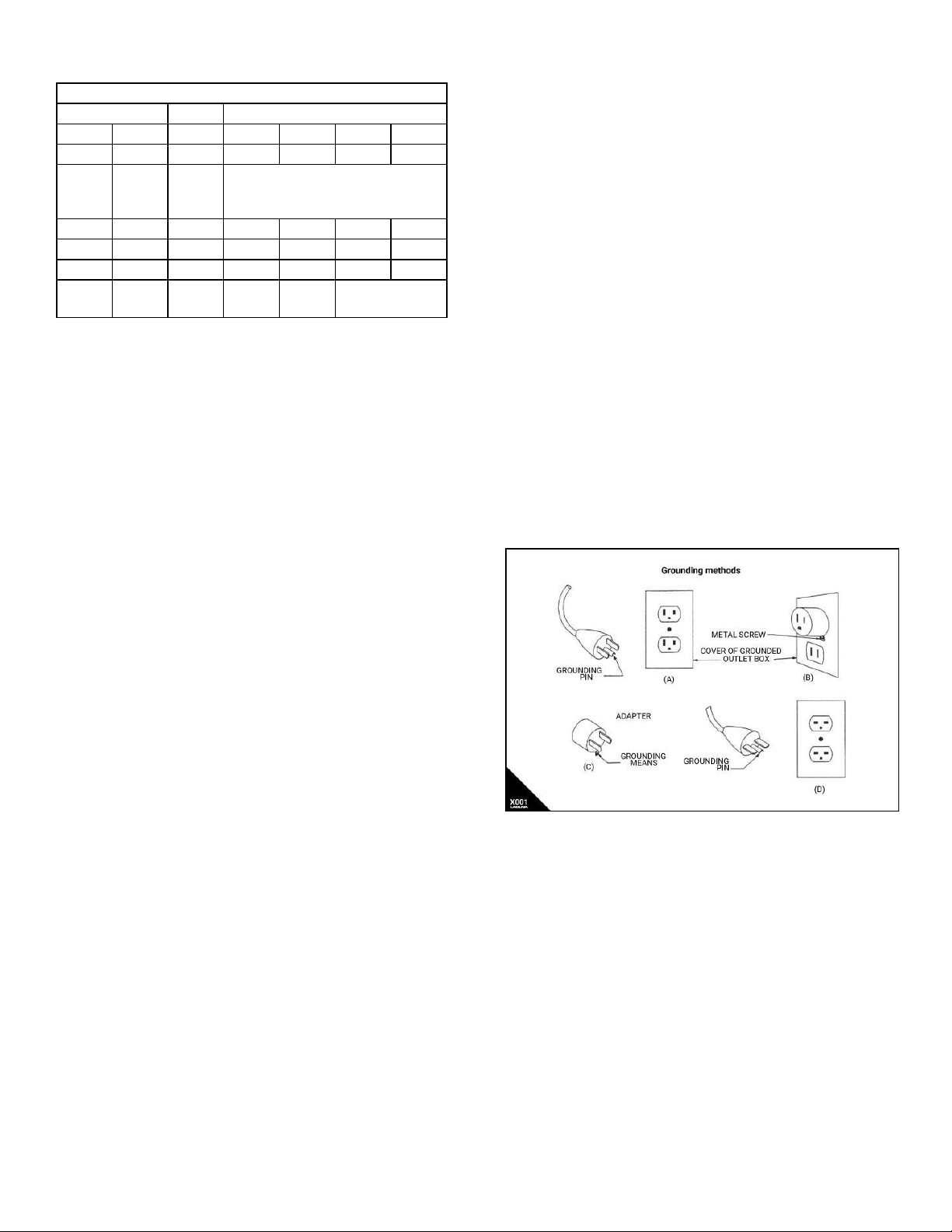

UTILISEZ UNE RALLONGE ÉLECTRIQUE

APPROPRIÉE. Assurez-vous que votre rallonge

électrique est en bon état et que le calibre du filage

soit adéquat pour transporter le courant que la

machine a besoin. Une rallonge de trop faible calibre

induira une perte d'intensité du voltage, ce qui

provoquera une surchauffe et une perte de

puissance. Le tableau A indique le bon calibre à u

liser en fonc on de la longueur de la rallonge et de la

demande en intensité du moteur. En cas de doute, u

lisez la rallonge de calibre plus fort. Plus le numéro

est pe t, plus la rallonge est de fort calibre.

10.

PORTEZ DES VÊTEMENTS APPROPRIÉS. Ne portez

pas de vêtements amples, des gants, des colliers,

des bracelets, ou tout autre bijou ou accessoire qui

pourrait être entraîné par des pièces mobiles. Des

souliers à semelle an dérapante sont également

recommandés. achez les cheveux longs et portez un

bonnet pour contenir la chevelure trop abondante.

11.

PORTEZ DES LUNETTES DE PROTECTION. Portez

également un masque contre la poussière si le

travail exécuté dégage de la poussière. Veuillez

prendre note que les lune es de prescrip ordinaire

ne résistent pas aux impacts et qu'elles ne sont pas

homologuées à re de lune es de sécurité.

12.

IMMOBILISEZ VOTRETRAVAIL. lisez des serres ou

un étau pour immobiliser votre travail lorsque c'est

possible. C'est plus sécuritaire que d'u liser votre

main, et ça permet de libérer vos deux mains pour

opérer l confortablement.

13.

NE VOUS ÉTIREZ PAS AU-DESSUS DE LA

MACHINE. Demeurez solidement enéquilibre sur

vos pieds en tout temps.

14.

ENTRETENEZ LES OUTILS AVEC SOIN. Gardez les

ls de coupe tranchants et propres pour en rer les

meilleures performances. Suivez les ins du fabricant

pour la lubrifica on et l'entr en des accessoires.

15.

DÉBRANCHEZ LES OUTILS avant d'en effectuer

l'entr en ou lors du changement d'accessoires tels

que lames ou couteaux.

16.

RÉDUISEZ LES RISQUES DE DÉMARRAGE NON

INTENTIONNEL. Assurez-vous que l'interrupteur est

en posi on fermée avant le branchement d'un ou l.

17.

UTILISEZ LES ACCESSOIRES RECOMMANDÉS.

Consultez le manuel d'instru pour connaître les

accessoires recommandés. L'u lisa on d'accessoires

inappropriés pose des risques de blessures aux

lisateurs.

18.

NE VOUSTENEZ JAMAIS DEBOUT SUR UNE

MACHINE. Des blessures graves pourraient survenir

si la machine bascule ou si les ls coupants sont

touchés accidentellement.

19.

VÉRIFIEZ LES PIÈCES ENDOMMAGÉES. Avant de

poursuivre l'u lisa on d'un l, tout disposi f de prot ou

toute pièce endommagée devra être inspecté pour

déterminer si elle peut fonc onner correctement et

selon l'u lisa on qui en est prévue. Vérifiez

l'alignement des pièces mobiles à savoir s'il y a

blocage, un bris, ou toute autre co on qui nuirait à

son lisa on. Une pièce ou un protecteur endommagé

doit être réparé ou remplacé.

20.

SENS D'ALIMENTATION. Alimentez la pièce vers la

lame ou le couteau dans le sens contraire de sa rota

on seulement.

21.

NE LAISSEZ JAMAIS UN OUTILFONCTIONNER

DANS SURVEILLANCE–ÉTEIGNEZ L'OUTIL. Ne

laissez pas l'ou l sans surveillance jusqu'à cequ'il

s'arrête complètement.