Instructions,

Platinum Resistance Thermometer Installation

Form Number F022-00-00 Revision F — ©2017 Lake Shore Cryotronics, Inc. — 2 May 2017 — Page 4

HEAT SINKING/THERMAL ANCHORING

1. Since the area being measured is read through the

body of the sensor, heat flow through the connecting

leads can create an offset between the sensor and

the true sample temperature. Thermal anchoring of

the connecting wires is necessary to ensure that the

sensor and the leads are at the same temperature as

the sample.

2. Connecting wires should be thermally anchored at

several temperatures between room temperature and

cryogenic temperatures to guarantee that heat is not

being conducted through the leads to the sensor.

Two different sizes of copper bobbins are available

from Lake Shore for heat sinking connecting leads:

P/N 9007-900 (large) and 9007-901 (small).

3. If connecting wires have a thin insulation such as

Formvar or polyimide, a simple thermal anchor can be

made by winding the wires around a copper post,

bobbin, or other thermal mass. A minimum of five

wraps around the thermal mass should provide

sufficient thermal anchoring. However, if space

permits, additional wraps are recommended for good

measure. To maintain good electrical isolation over

many thermal cycles, it is good practice to first varnish

a single layer of cigarette paper to the anchored area,

and then wrap the wire around the paper and bond in

place with a thin layer of IMI 7031 varnish. Formvar

wiring insulation has a tendency to craze with the

application of IMI varnish. If used, the wires cannot be

disturbed until the varnish is fully cured and all

solvents have evaporated (typically 12 to 24 h).

4. A final thermal anchor at the sample itself is good

practice to ensure thermal equilibrium between the

sample and temperature sensor.

CALIBRATED SENSORS

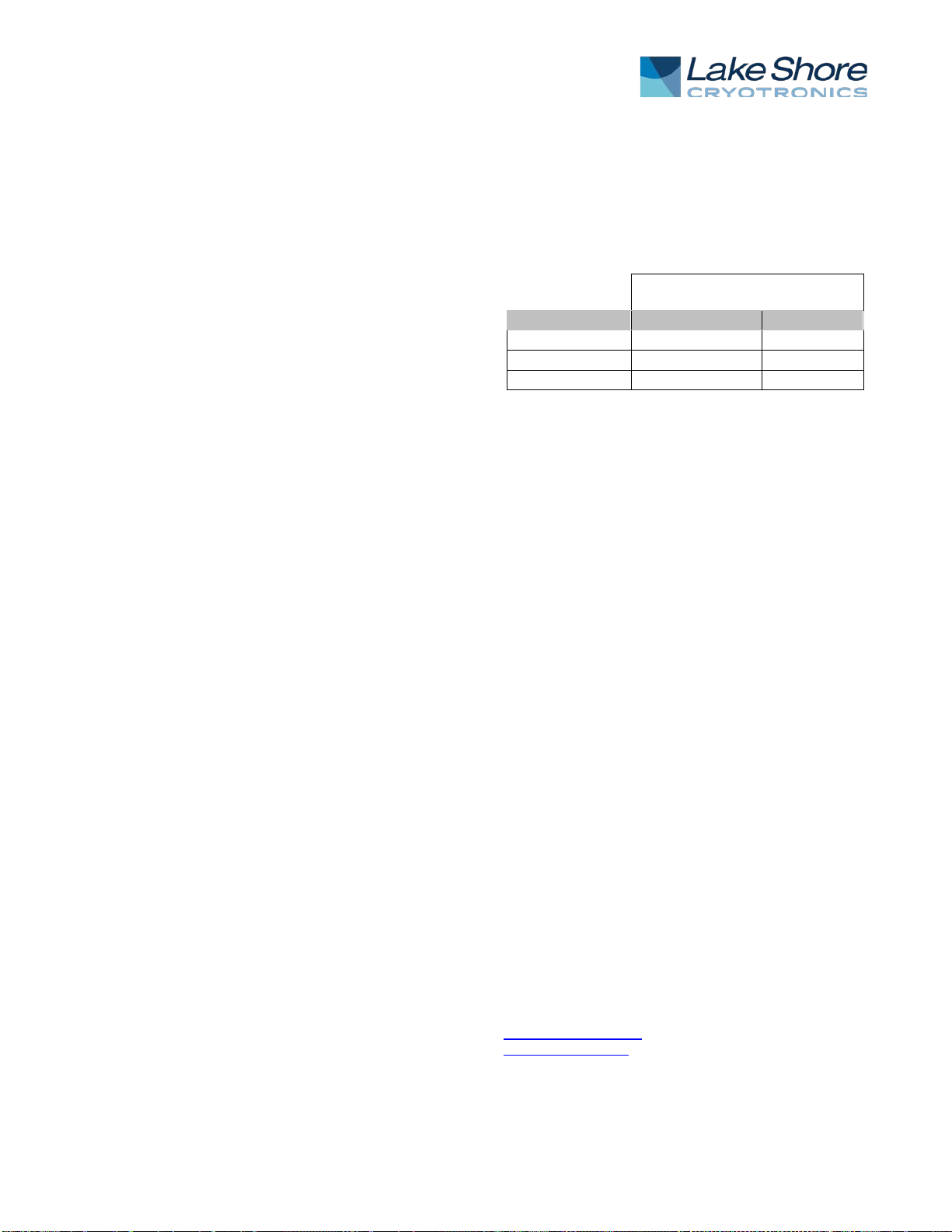

As a 2-lead device, the resistance of a platinum sensor’s

leads is included in the measured resistance during

calibration. Cutting the leads to a shorter length, tinning a

greater portion of the lead length with solder, or otherwise

changing the point of lead attachment will affect the overall

measurement even if a 4-lead measurement is made to

the point of connection with the sensor leads. Additionally,

the lead material is not pure platinum, but rather an alloy

or coated wire used to increase solderability and provide a

more robust lead. The lead material is Pt-Rh (5%) alloy

wire for the PT-103, platinum-coated palladium wire for the

PT-102, and platinum-coated nickel wire for the PT-111.

During calibration at Lake Shore, contact to each lead is

made within 1 mm of the lead end. An estimate of the

calibration shift for each 1 mm lead length change is given

below for each of the three models. For the PT-103 sensor

(which shows a relatively significant lead error below

30 K), the two sensor leads are branched into four leads

prior to calibration, and the sensor is delivered with the

four leads attached. The extensions are bare nickel wire

brazed to the sensor leads using Fusion Inc. LHK-1235-

701 silver brazing paste.

Calibration shift (mK) per 1 mm

CRYOGENIC ACCESSORIES — Recommended for

proper installation and use of platinum sensors

Stycast®Epoxy 2850FT (P/N 9003-020, 9003-021):

Permanent attachment, excellent low temperature

properties, poor electrical conductor, low cure shrinkage.

Apiezon®N Grease (P/N 9004-020): Low viscosity, easy

to use, solidifies at cryogenic temperatures, excellent

lubricant.

IMI 7031 Varnish (P/N 9009-002): Nonpermanent

attachment, excellent thermal conductor, easy to apply

and remove.

Indium Solder (P/N 9007-002-05): 99.99% pure, excellent

electroplating material, foil form.

90% Pb 10% Sn Solder (P/N 9008-001): Greater lead

content for higher temperature applications no greater

than 200 °C.

Phosphor Bronze Wire (P/N 9001-00X): Available in

single, duo, and quad strands, no magnetic attraction, low

thermal conduction.

Manganin®Wire (P/N 9001-00X): Low thermal

conductivity, high resistivity, no magnetic attraction.

Heat Sink Bobbin (P/N 9007-900 large, 9007-901 small):

Gold-plated oxygen-free high-conductivity (OFHC) copper

bobbins.

Instruments: Lake Shore sells a complete line of

instrumentation for use with platinum sensors, including

current sources, cryopump monitors, temperature

controllers, monitors and thermometers, temperature

scanners and transmitters.

For complete product description and detailed

specifications on the above accessories and instruments,

consult the Lake Shore Temperature Measurement and

Control Catalog, call (614) 891-2243, e-mail

sales@lakeshore.com, or visit our website at

www.lakeshore.com.