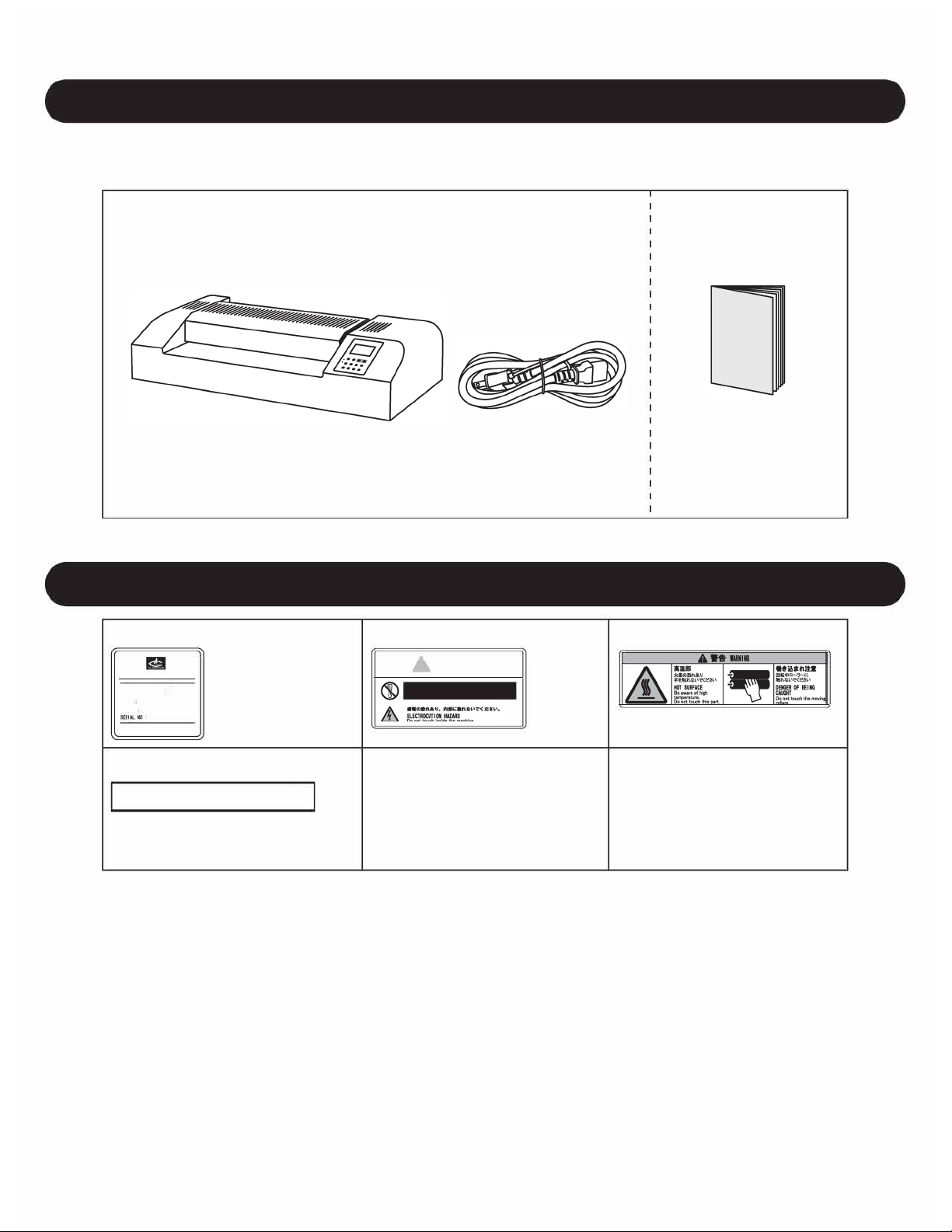

Precautions for use

& Warning

To remove the plug from the receptacle, hold the plug housing.

Do not use other power ratings than that specified.

No multiple connections from a single receptacle are permissible. Make sure that the power plug is inserted to

the deepest position.

Electric shock or fire may otherwise occur. To handle a power cord, fol low the precautions

shown below

.

Do not modify power cords.

Do not subject the cord to heavy loads.

Avoid excessive bend. Twist. Or pull.

Avoid placing the power cord near heating elements or apparatuses.

*If the power cord fails. Contact your dealer.

Clean the power plug periodically. Remove the power plug from the receptacle and clean the root part of

and between the electrodes (blades).

Do not place flammables on the equipment. Do not drop the equipment.

Avoid high temperature or humid, ill-ventilated, or dusty environment.

@

No dismantling or modification permissible.

Do not use the equipment when it is abnormal e.g. smoking or smelling. The equipment may

disconnect the power plug. Contact the seller or our company. For reason of safety, no repair by the

customer is permissible.

&caution

sure that the power connection is already removed.

For long disuse. Remove the power plug from the receptacle.

®

Do not use wet hand to remove or insert the plug.

Before power connection, ground connection should

be made. To remove the ground make

Do not install or store the equipment in such a place that can be accessed by children.

The

Avoid

equipment

unstable

may

(shaking o

otherwise

r

fa

inclined)

l I or tu

floor.

mble down, leading to injury.

Do not ride on or place a heavy material on the equipment.

During the machine's operation or your action for inserting a film, your accessories such as

necktie and necklace or hair may be caught in the rol Iers assembly, leading to exposing you to

deformation of the rubber rol Iers at the contact part.

great danger.

Glue or other contaminants on the surface of the laminate rol Iers should be removed. Wipe with a wel I-

squeezed, neutral detergent soaked cloth.

*Do not use solvent (benzene). thinner, brush. etc.

When not in use, keep the upper rol Ier of the laminate rol Ier assembly at the raised position. Leaving

the pair of upper and lower rollers in contact with each other may lead to the

Avoid direct sunlight.

The rollers are made of rubber and may otherwise be degraded quickly. When not in use, cover the

equipment to prevent it from being directly exposed to the sun or fluorescent I ight.

To move the equipment, turn off the power switch and remove the power plug from the receptacle.

03

Do not use damaged power cords.

Do not leave metallic things, flammables, or liquid in the equipment.

otherwise cause electric shock or fire to occur. Immediately turn off the power switch and

Leon13DX