Characteristics of Product

Lotus-14LK-H is a pack-type laminator that supports up to 3 size. It can be used for wide range of

uses from black-and-white photocopy to menu. lso, stable outcomes and high quality laminate

processing can be secured during continuous use for long time.

Major characteristics of this product are as follows.

Stable thermal following characteristic

Stable thermal following characteristic was embodied by selecting external heating roller.

High quality laminate process is made possible during mass processing and post processing.

High speed processing with 10 rollers

6 external heating rollers are included. Heat is accurately delivered to the laminate film during

high speed processing.

lso, 4 tension rollers on the back polish the processed object.

Temperature and speed setting function included

Temperature and speed can be independently configured for optimal design for different

laminates according to laminate film thickness and paper type.

Simple operation using LCD

convenient LCD operation panel is placed on the front side. Current process setting can be

checked at a glance, and setting can be simply changed using a button.

Safe design

Once processing work is done, COLD button is used to cool the laminate roller heated to high

temperature. COLD function substantially improves durability of the roller.

Immediate response to urgent processing

「ST NDBY」 button is available on the operation panel. This button is used to maintain standby

status while preheating (about 80℃).

Immediate shutdown using up-down le er

When processing work is complete, top roller and bottom roller can be dropped down to the

side lever, allowing immediate shutdown.

※ If this function is used frequently without using COL function, lifetime of the roller can be shortened.

Please only use this function during emergency.

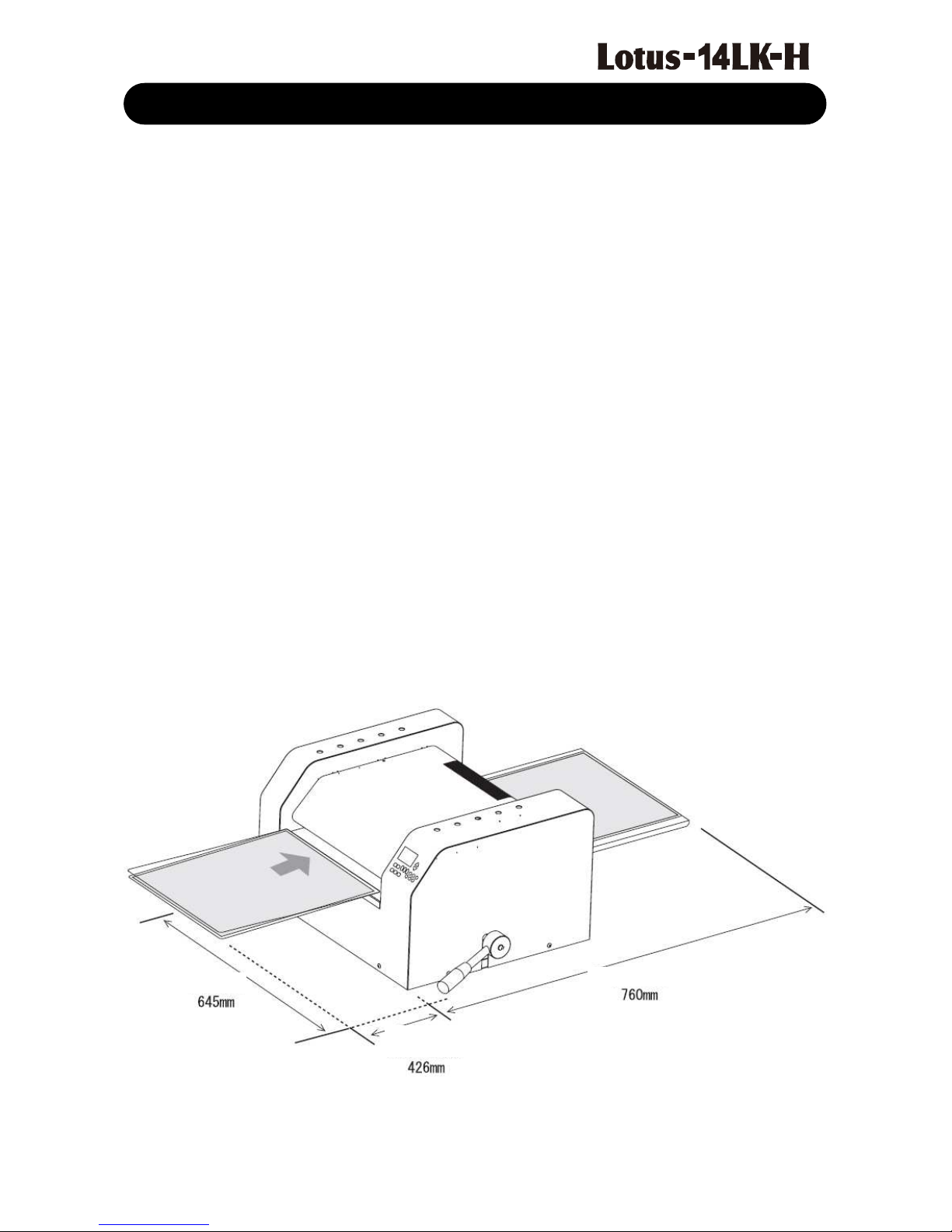

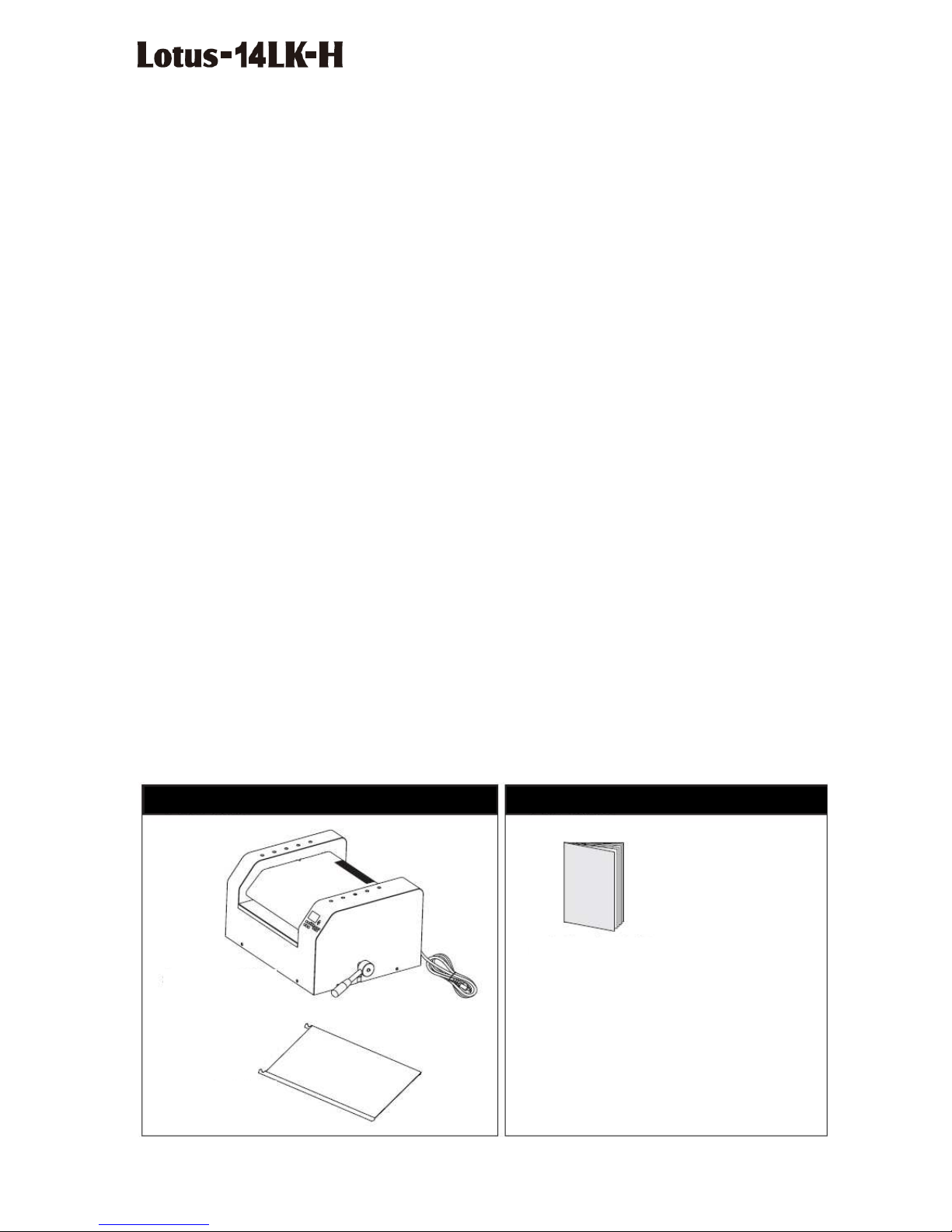

Confirmation of Parts

The main body includes the following parts and documents.

If the product is missing a part, contact a nearby branch of our company or the store of purchase.